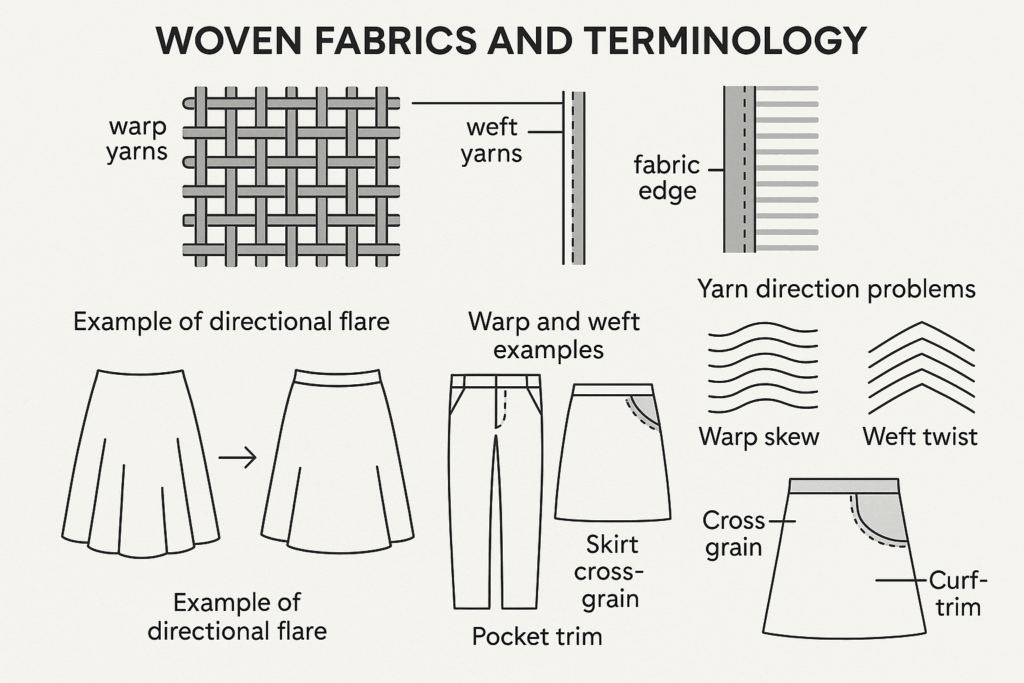

Woven Fabrics and Terminology: Warp, Weft, Yarn Direction, and Garment Construction

🧵 Understanding Woven Fabrics

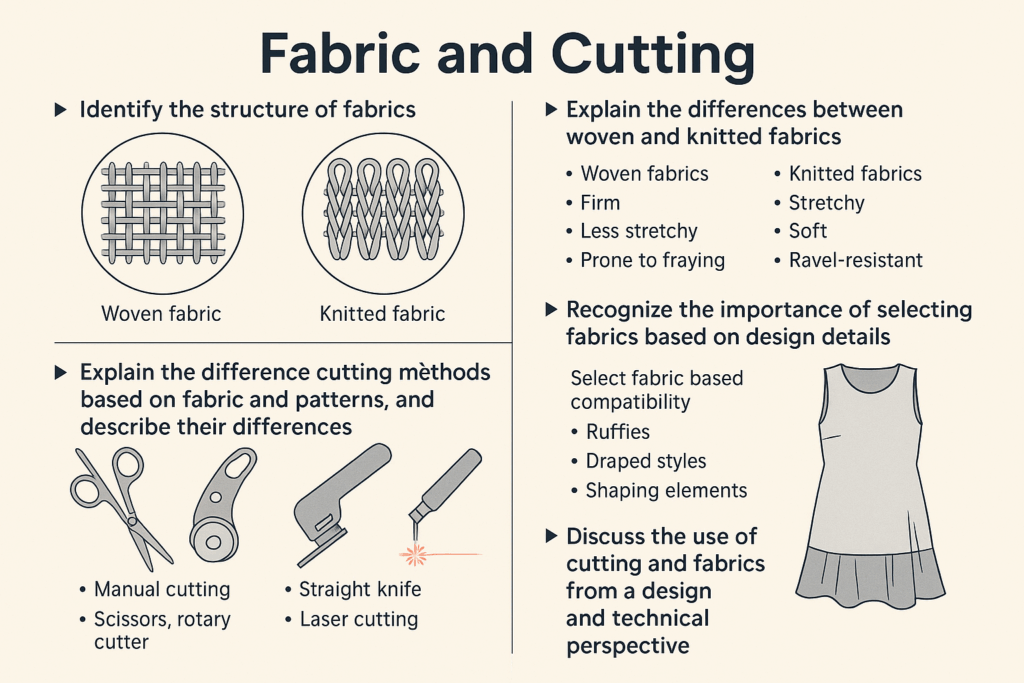

Woven fabrics are made by interlacing warp and weft yarns at right angles. They offer stability, structure, and durability, making them ideal for garments that require form retention, such as trousers, blazers, skirts, and shirts.

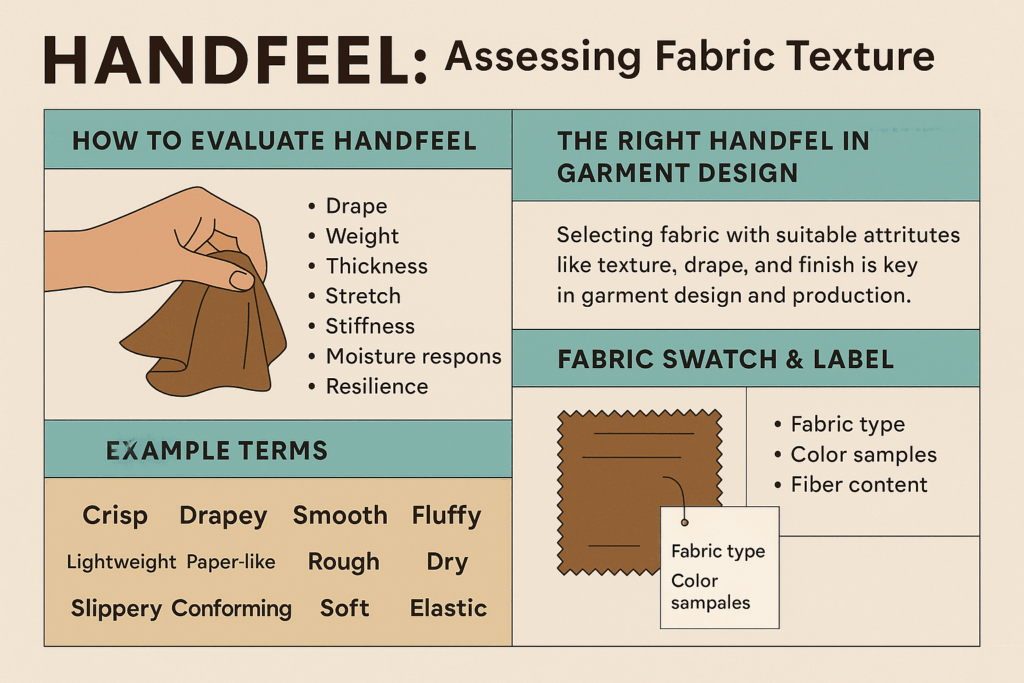

A deep understanding of woven fabric construction—including yarn direction, edge treatment, and weave stability—is essential for fashion designers, technical developers, and manufacturers.

🔸 Key Terms in Woven Fabric Structure

| Term | Description |

|---|---|

| Warp yarn | Vertical threads set on the loom; under tension during weaving |

| Weft yarn | Horizontal threads woven between warp threads |

| Fabric edge | Finished edge running parallel to warp yarns; strengthened and hemmed |

| White fabric | Undyed and unprocessed woven fabric, used as a base for dyeing or printing |

| Straight grain | Direction of the warp yarn; most stable and ideal for cutting major panels |

| Cross grain | Direction of the weft yarn; slightly more elastic than warp yarn |

🔧 Fabric Edge and Stability

The edges of woven fabrics, also known as selvedges, are stronger than the inner body because:

- They are reinforced with thicker yarns

- During production, they are fixed to the stenter machine with needles, leaving small visible holes

- These selvedges guide finishing processes like stretching, flattening, and heat-setting

📌 Proper handling during these steps is crucial. Poor edge treatment can lead to warp skew or bowing, visible in distortion of printed patterns.

⚖️ Yarn Direction: Why It Matters in Garment Cutting

Cutting along the straight grain (warp direction) ensures:

- Maximum shape retention

- Prevents fabric from twisting, curling, or draping unevenly

- Ensures even hem alignment and fit in symmetrical garments

🔺 Misalignment Problems

| Issue | Cause | Impact |

|---|---|---|

| Warp Skew | Improper weaving tension | Visual distortion of stripes |

| Weft Twist | Poor feed rate between fabric edges | Pants legs twist or misalign |

| Directional Flare | Cutting not aligned to warp | Uneven skirt flare or seam twist |

📌 In Figure 7.6, a skirt hem flares more on one side due to inconsistent yarn direction.

🧥 Garment Examples: Warp vs. Weft Usage

| Garment Part | Preferred Yarn Direction | Reason |

|---|---|---|

| Main panels (e.g., pants legs, skirt body) | Warp (straight grain) | Structure, drape, long-term shape retention |

| Back yoke & cuffs of men’s shirts | Bias or cross-grain | Adds slight elasticity for comfort |

| Waistbands of skirts | Cross-grain | Controlled stretch for fit |

| Pocket openings | Bias or straight grain | Reinforces stress areas without adding bulk |

✂️ Cutting along the wrong grain to save fabric may reduce costs, but it often compromises garment symmetry, fit, and quality.

🪡 Handling Weaving Defects

Common structural problems in woven fabric include:

- Warp twist or bowing (Figure 7.8): Distorts linear or stripe designs

- Weft misalignment (Figure 7.7): Results in post-wash puckering or seam distortion

- Printing over flawed yarn alignment can temporarily hide errors—but they often reappear after laundering

📌 Summary

Mastering woven fabric terminology and behavior is essential in garment development. Proper understanding of warp and weft direction, edge structure, and fabric stability ensures that garments maintain their fit, shape, and visual balance over time.

From planning to production, woven fabric direction must be respected—both for aesthetic appeal and functional durability.