Introduction: What is Edge Finish (EF)?

Edge Finish (EF) refers to the techniques used to finish the raw edges of single-ply fabrics to prevent fraying and to give a polished, clean look. It’s an essential step in garment construction, ensuring that the edges of a fabric are neat and professionally finished, which enhances the durability and appearance of the final product.

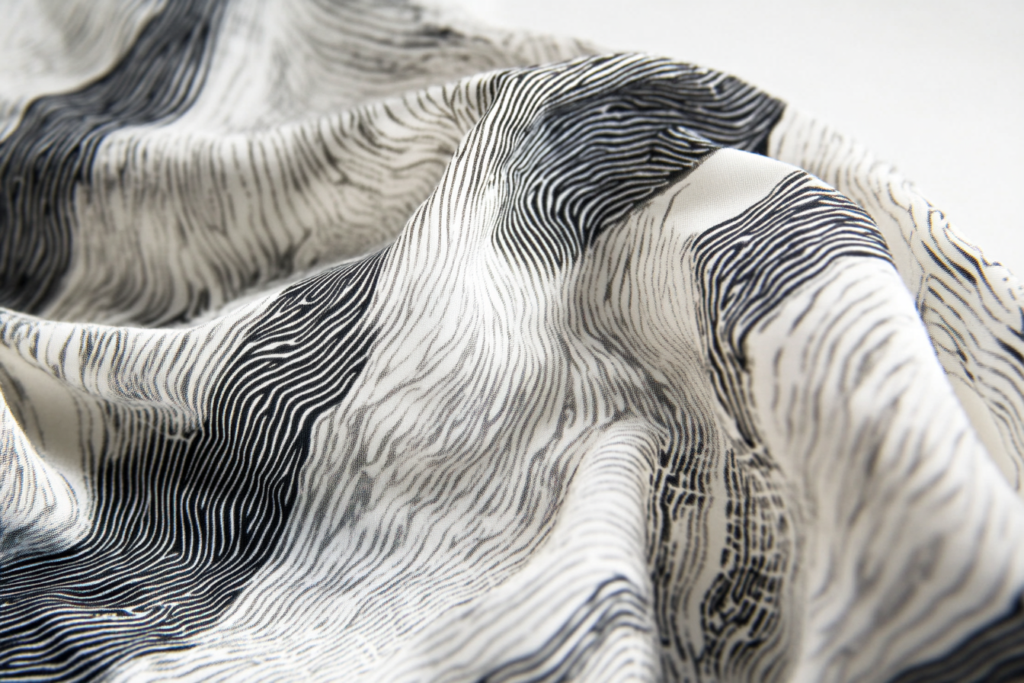

In fashion design, the raw edges of fabrics, especially single-ply fabrics, are vulnerable to unraveling or fraying over time. By applying an edge finish, the fabric is not only secured but also provided with a more aesthetically pleasing appearance. This technique can be used for a variety of fabrics, ranging from delicate materials like chiffon to heavier textiles like cotton and linen.

How is Edge Finish (EF) Applied?

There are several methods for applying Edge Finish (EF), each suited for different types of fabrics and designs. Below are some of the most common techniques used in the industry:

- Overlocking/Serger Stitch:

- Overlocking or using a serger is one of the most popular methods for finishing edges. It’s ideal for fabrics that are prone to fraying. A serger stitches over the raw edge, simultaneously trimming the fabric and sealing the edge to prevent further unraveling.

- Zigzag Stitch:

- The zigzag stitch is a versatile edge finishing method that can be done on a regular sewing machine. It helps secure the fabric’s edge by preventing fraying. This technique works well for lightweight to medium-weight fabrics.

- Bias Tape:

- For more decorative edge finishes, bias tape can be used. This method involves wrapping the raw edge with a strip of bias-cut fabric and stitching it down. It’s commonly used on lightweight fabrics and is a great way to add contrast or decorative detail to a garment.

- French Seam:

- A French seam is often used for delicate fabrics or in situations where the inside of a garment should look as neat as the outside. This method encloses the raw edge within the seam, giving a clean, professional finish.

- Rolled Hem:

- A rolled hem is ideal for lightweight, sheer fabrics, creating a small, neat hem that rolls under the fabric edge. This method is commonly used in garments such as skirts or blouses made from delicate fabrics like silk or chiffon.

Why is Edge Finish (EF) Important?

- Prevents Fraying:

- One of the primary purposes of an edge finish is to prevent the fabric from fraying. Single-ply fabrics, especially those that are woven, are prone to losing threads along the raw edges, which can weaken the garment over time.

- Enhances Durability:

- A well-applied edge finish improves the garment’s durability by ensuring that the fabric edges remain intact. This is especially important in high-stress areas like armholes, hems, and side seams.

- Improves Appearance:

- Edge finishes not only protect the fabric but also contribute to the garment’s overall aesthetic. Clean, well-finished edges provide a professional, polished look, elevating the quality of the final product.

- Prepares for Final Sewing:

- In many garments, especially those made from materials like wool or jersey, the edge finish is the first step before other processes, such as hemming or seam stitching, are completed. It ensures that the fabric can be sewn together without unnecessary bulk or fraying.

Common Applications of Edge Finish (EF) in Fashion Design

- Tops and Dresses:

- For blouses, tops, and dresses, applying an edge finish to armholes, necklines, and side seams ensures that the garment not only fits well but has a clean, finished look.

- Skirts and Pants:

- Edge finishes on the waistlines, hems, and inseams of skirts and pants are crucial to prevent the edges from fraying, especially when using fabrics that tend to unravel easily.

- Outerwear:

- Jackets, coats, and other outerwear garments often use edge finish techniques such as overlocking or bias tape to secure the edges of fabric and ensure they last through prolonged wear.

- Lingerie and Intimate Apparel:

- In lingerie and intimate apparel, edge finishing is vital to ensure that the fabric remains in place, especially around sensitive areas like the waistband or leg openings. Rolled hems and bias binding are often used for a more delicate finish.

Conclusion: Why Edge Finish (EF) is Essential in Garment Construction

An Edge Finish (EF) is an essential step in garment construction that protects raw edges, prevents fraying, and adds a clean, professional touch to the final product. Whether you use an overlocker, bias tape, or rolled hem, this technique ensures that your garments maintain their shape and appearance over time. It’s a small but significant detail that contributes to the overall quality of the garment, making it an indispensable part of the fashion design process.

By incorporating edge finishing methods into your sewing process, you can create garments that not only look polished but also stand the test of time. Understanding how to apply the appropriate edge finish for each fabric type ensures that every garment you make is finished to the highest standards.