Lapped Seam (LS): A Durable and Clean Sewing Method for Structured Garments

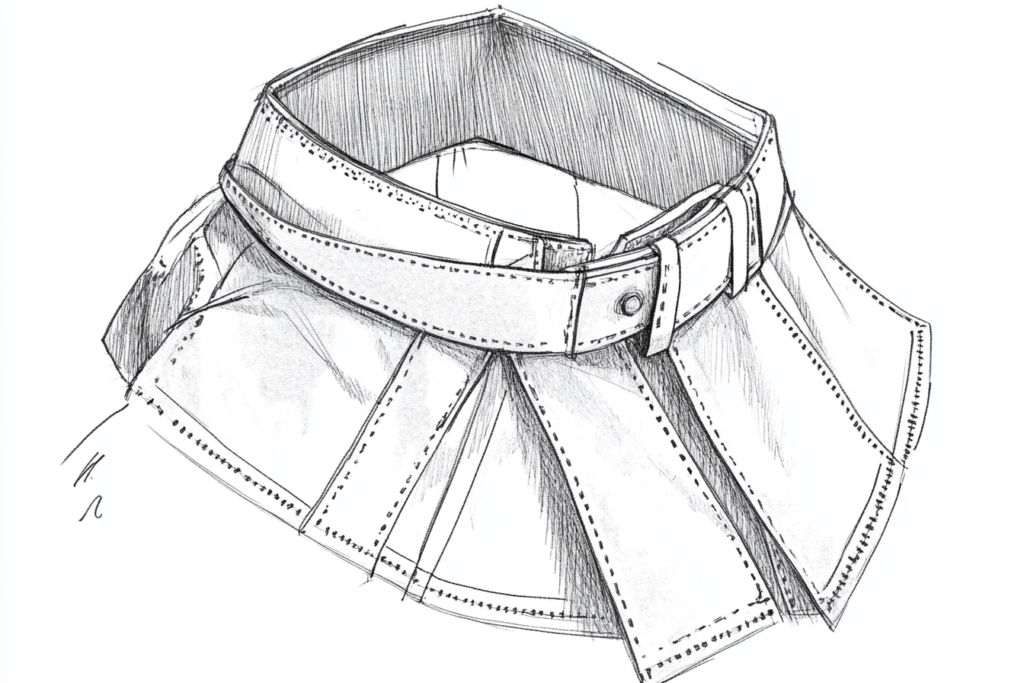

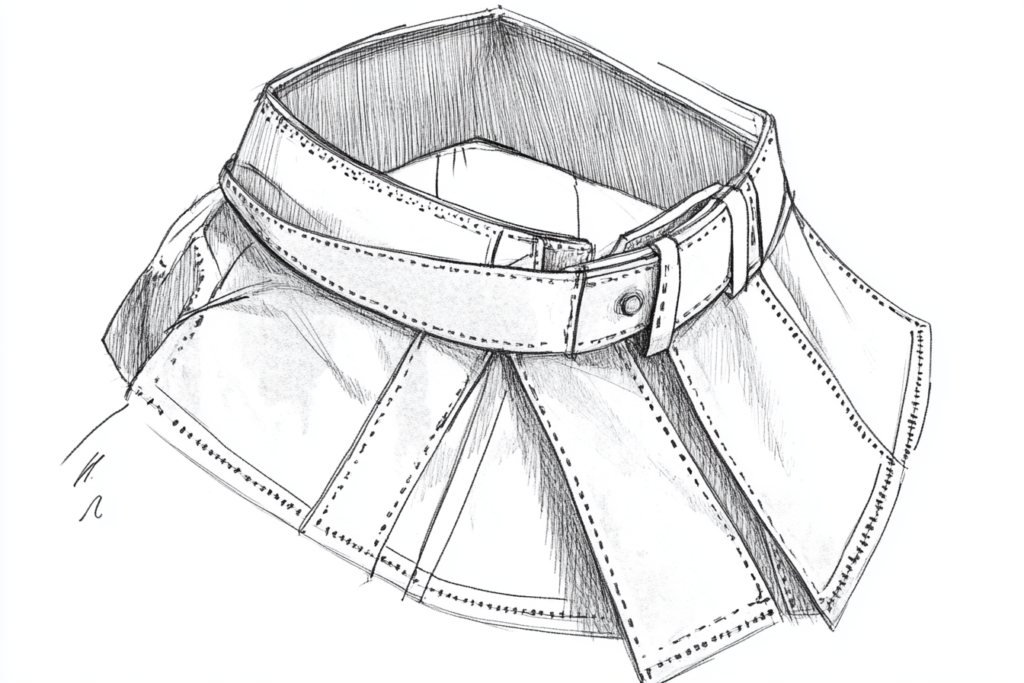

Meta Description: A lapped seam (LS) is a sewing technique that wraps raw fabric edges inside for durability and a clean finish. Commonly used in collars, shirt sleeves, and waistbands.

What is a Lapped Seam (LS)?

A lapped seam (LS) is a sewing method where one fabric layer overlaps another, enclosing the raw edges for a clean, reinforced finish. This technique is widely used in structured garments such as collars, shirt sleeves, trouser waists, and skirt waistbands.

Lapped seams are valued for their strength, durability, and neat appearance, making them ideal for casual and formalwear, as well as workwear and outerwear.

Key Features of a Lapped Seam

✔ Encloses Raw Edges – Prevents fraying and ensures a smooth interior finish.

✔ Stronger Than Basic Seams – Provides extra reinforcement, reducing seam stress.

✔ Common in Collars, Sleeves & Waistbands – Used in structured and high-movement areas.

✔ Creates a Clean & Professional Look – Seen in tailored shirts, trousers, and uniforms.

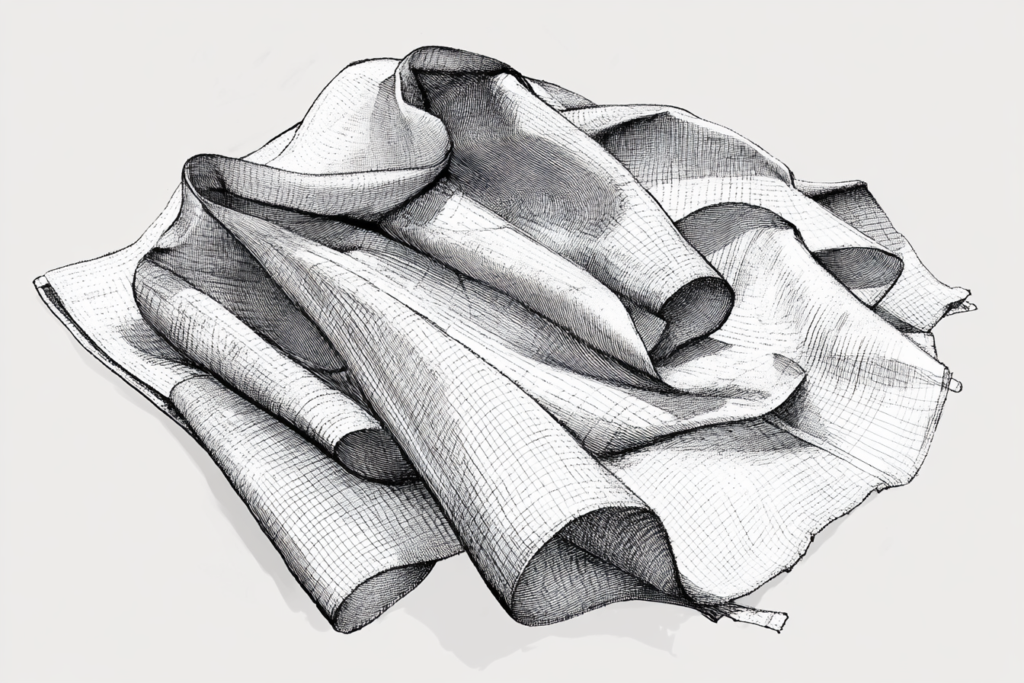

✔ Suitable for Thick & Medium-Weight Fabrics – Works well with denim, cotton, and twill fabrics.

How a Lapped Seam is Constructed

1️⃣ One fabric layer overlaps another – Instead of placing fabric edges together, one piece is folded over the other.

2️⃣ Raw edges are enclosed inside the seam – This creates a neat, finished edge.

3️⃣ Topstitching secures the seam – Provides extra strength and a decorative touch.

Lapped seams can be sewn with single or double stitching, depending on the fabric type and required durability.

Common Uses of Lapped Seams in Fashion

📌 Collars & Shirt Sleeves – Ensures a structured and polished appearance.

📌 Trousers & Skirt Waistbands – Provides stability and durability in fitted garments.

📌 Denim & Workwear – Adds extra strength to seams exposed to frequent movement.

📌 Outerwear & Jackets – Used in heavy fabrics like wool, twill, and leather.

📌 Decorative Stitching in Topstitched Designs – Often seen in casual and tailored styles.

Lapped Seam vs. Other Seam Types

| Feature | Lapped Seam (LS) | Flat-Felled Seam | French Seam | Overlocked Seam |

|---|---|---|---|---|

| Construction | One fabric layer overlaps another | Raw edges are enclosed & stitched flat | Seam is folded inside for a clean finish | Edges are trimmed and overlocked |

| Strength | High | Very high | Medium | Moderate |

| Best For | Structured garments (shirts, trousers, skirts) | Denim, workwear, uniforms | Lightweight fabrics (silk, chiffon) | Stretch fabrics, casual wear |

| Appearance | Visible topstitching | Double-stitched, reinforced | Hidden seam | Finished with overlock thread |

Lapped seams provide a balance of strength and clean finishing, making them versatile for both casual and formal clothing.

How to Sew a Lapped Seam

✔ Step 1: Overlap the two fabric pieces, ensuring the raw edges are enclosed.

✔ Step 2: Pin the layers together, aligning them for a straight, even seam.

✔ Step 3: Stitch along the overlapped edge with a single or double row of stitching.

✔ Step 4: Press the seam flat for a smooth, professional finish.

💡 Tip: Use a twin needle for topstitching to create a decorative effect on denim or casualwear.

Why Choose a Lapped Seam?

✔ Stronger & More Durable Than Basic Seams – Ideal for high-movement areas.

✔ Neat, Professional Finish – Common in tailored and structured clothing.

✔ Prevents Fabric Fraying – Works well for medium to heavyweight fabrics.

✔ Enhances Design & Stitching Detail – Perfect for topstitched garments and workwear.

Conclusion: The Versatility of Lapped Seams in Garment Construction

Lapped seams offer a balance of durability, neatness, and flexibility, making them essential in tailored shirts, structured trousers, and workwear. Their clean finish and reinforced stitching ensure garments maintain both style and strength.

From formal dress shirts to rugged denim jeans, lapped seams continue to be a trusted sewing technique in fashion and textile production.