Marker: The Blueprint for Efficient Fabric Cutting in Garment Production

Meta Description: A marker is a paper layout that arranges all garment panels in the most fabric-efficient way for batch cutting. Learn how markers optimize material use in the fashion industry.

What is a Marker in Garment Manufacturing?

A marker is a paper layout that contains all the garment panels arranged in an optimal way to minimize fabric waste. It is placed on multiple layers of fabric before cutting, ensuring efficient material utilization and accurate pattern placement in mass production.

Markers are essential in apparel manufacturing, tailoring, and textile production, helping to reduce fabric costs and improve cutting precision.

Key Features of a Marker in Fabric Cutting

✔ Contains All Garment Panels – Shows the most efficient fabric layout.

✔ Used for Batch Cutting – Guides mass production cutting processes.

✔ Optimizes Fabric Usage – Reduces material waste and production costs.

✔ Ensures Pattern Accuracy – Prevents fabric misalignment and inconsistencies.

✔ Can Be Manually or Digitally Created – Designed by hand or using CAD software.

Types of Markers in Fashion Production

1. Manual Marker

- Created by hand using paper and a tracing process.

- Common in small-scale or custom production.

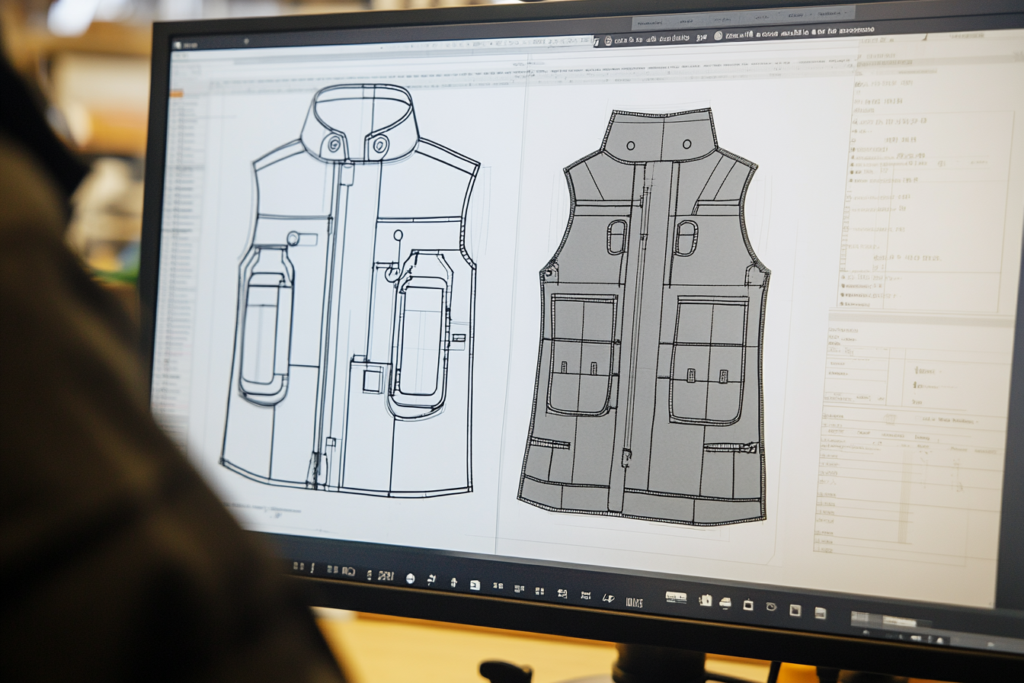

2. Computerized (CAD) Marker

- Designed using CAD (Computer-Aided Design) software.

- More precise and fabric-efficient than manual methods.

- Used in high-volume manufacturing.

3. Mixed Marker

- Combines manual and digital techniques.

- Used when some garment parts require manual adjustment for better efficiency.

Where Are Markers Used in the Apparel Industry?

📌 Mass Production Factories – Guides bulk fabric cutting for consistent sizing.

📌 Tailoring & Custom Garment Making – Helps maximize fabric use in custom designs.

📌 Textile Mills & Cutting Rooms – Ensures precise and uniform cutting processes.

📌 Home Sewing & Pattern Making – Used by designers to plan efficient fabric cutting.

📌 Eco-Friendly & Sustainable Fashion – Reduces fabric waste in sustainable clothing production.

How a Marker Improves Fabric Cutting Efficiency

1️⃣ Garment panels are arranged on the marker to fit within the fabric width.

2️⃣ The marker is placed on stacked fabric layers for batch cutting.

3️⃣ Cutters follow the marker outline to ensure precise, consistent garment pieces.

4️⃣ Any excess fabric is minimized, reducing waste and production costs.

💡 Tip: Digital markers improve accuracy and efficiency, reducing material waste by up to 15% compared to manual layouts.

Marker vs. Fabric Layout vs. Lay-Up

| Feature | Marker | Fabric Layout | Lay-Up |

|---|---|---|---|

| Definition | A paper layout of garment panels for cutting | The way patterns are arranged on fabric | The process of layering fabric before cutting |

| Purpose | Ensures fabric efficiency | Maximizes pattern alignment | Prepares fabric for mass cutting |

| Common in | Industrial cutting rooms | Tailoring, garment production | Factory-based mass production |

💡 Tip: Markers ensure efficient cutting, while fabric layouts and lay-ups focus on proper pattern alignment and preparation.

Advantages of Using a Marker in Fashion Production

✔ Saves Fabric & Reduces Waste → Maximizes material efficiency.

✔ Improves Cutting Precision → Ensures consistent garment sizes.

✔ Increases Production Speed → Speeds up cutting room operations.

✔ Optimizes Cost Efficiency → Lowers fabric consumption costs.

✔ Works for Both Manual & Automated Cutting → Adaptable to different production scales.

Conclusion: The Role of Markers in Efficient Fabric Cutting

A marker is a crucial tool in garment manufacturing, ensuring fabric efficiency, precise cutting, and cost-effectiveness. Whether manually drawn or digitally generated, it helps manufacturers optimize material use while maintaining garment accuracy and quality.

For businesses looking to improve production efficiency and reduce waste, using well-planned markers is an essential step toward better fabric utilization and cost savings.