Superimposed Seam (SS): Understanding This Overlapping Stitching Method

Meta Description: A superimposed seam (SS) is a type of seam where two or more garment pieces overlap at one end, with edges neatly stacked and sewn. Learn more about its applications, advantages, and how it adds durability to garments.

What is a Superimposed Seam (SS)?

A superimposed seam (SS) is a type of seam in which two or more garment pieces are overlapped at one end, and the edges of the garment pieces are neatly stacked before being sewn together. This technique is commonly used in garment construction to join fabric layers, adding both strength and a clean finish.

Unlike other types of seams, the superimposed seam keeps the edges aligned and allows for neat, strong stitching, which is essential for maintaining the garment’s shape and integrity.

Key Features of a Superimposed Seam (SS)

✔ Overlapping Garment Pieces: The fabric layers are overlapped, making it an effective way to join two or more layers of material.

✔ Neatly Stacked Edges: The edges of the garment pieces are aligned or stacked neatly before being stitched, creating a clean appearance.

✔ Secure Stitching: The overlapping fabric is stitched together, providing strength and ensuring the seam remains intact over time.

✔ Versatile Application: Superimposed seams are used in both fashion design and industrial garment manufacturing.

✔ Durable: This type of seam ensures that the garment has a strong construction, suitable for high-stress areas like armholes and side seams.

How a Superimposed Seam (SS) Works

In a superimposed seam, two pieces of fabric are stacked on top of each other, with the edges aligned. The pieces are then sewn together using a straight or zigzag stitch. The goal is to make sure that the edges remain neatly aligned during stitching, which results in a secure, durable seam.

Here’s the process:

Step 1: Prepare the Fabric Pieces

Lay out the two fabric pieces that need to be joined. One piece will be placed on top of the other, slightly overlapping at the edges.

Step 2: Align the Edges

Ensure that the edges of the fabric are aligned perfectly before stitching. This is important for achieving a neat, clean look at the seam line.

Step 3: Sew the Seams

Sew through both layers of fabric, making sure the edges stay aligned as you stitch. The stitch should be secure enough to hold both pieces together.

Step 4: Finishing the Edges (Optional)

For a cleaner finish, the raw edges of the fabric can be serged or bound to prevent fraying. In some cases, a topstitch or coverstitch can also be applied to give the seam a more polished look.

Advantages of Superimposed Seams (SS)

1. Strong and Durable

Superimposed seams are especially strong, making them ideal for garments that experience a lot of stress, such as outerwear, activewear, and uniforms. The overlapping layers increase the seam’s resistance to tearing.

2. Neat Appearance

The stacked edges result in a clean, professional finish. This is particularly important in high-end garments, where the construction details are just as crucial as the design.

3. Prevents Fabric from Unraveling

Since the edges are neatly aligned and stitched together, this method prevents fabric edges from fraying and unraveling, ensuring that the garment maintains its shape over time.

4. Ideal for Certain Garment Types

This seam is perfect for garments that require overlapping fabric, such as jackets, coats, blouses, and even dresses. It’s especially useful for stress points like armholes and side seams.

Applications of Superimposed Seams

Superimposed seams are widely used across various types of garments and textile applications:

📌 Casual Wear and Outerwear

- Superimposed seams are common in jackets and coats, where the fabric layers need extra strength and durability.

📌 Workwear and Uniforms

- This seam is also used in workwear, such as overalls, aprons, and uniforms, to withstand the rigors of daily use.

📌 Activewear

- For sportswear or activewear, superimposed seams provide flexibility and comfort while ensuring that the garment can endure frequent movements.

📌 Home Décor and Upholstery

- Superimposed seams are used in upholstery, where the seams need to be strong and clean to support wear and tear.

Superimposed Seam vs. Other Seaming Techniques

| Seam Type | Superimposed Seam (SS) | French Seam |

|---|---|---|

| Appearance | Clean and neat with stacked edges | Encased edges, providing a polished finish |

| Durability | Strong and resistant to wear | Less durable in heavy-use areas |

| Ideal Use | High-stress areas like side seams, armholes | Light fabrics, delicate garments |

| Production Speed | Fast and efficient in mass production | Requires more time and attention to detail |

| Finish | Simple, with optional edge finishing | Encloses raw edges for a neater look |

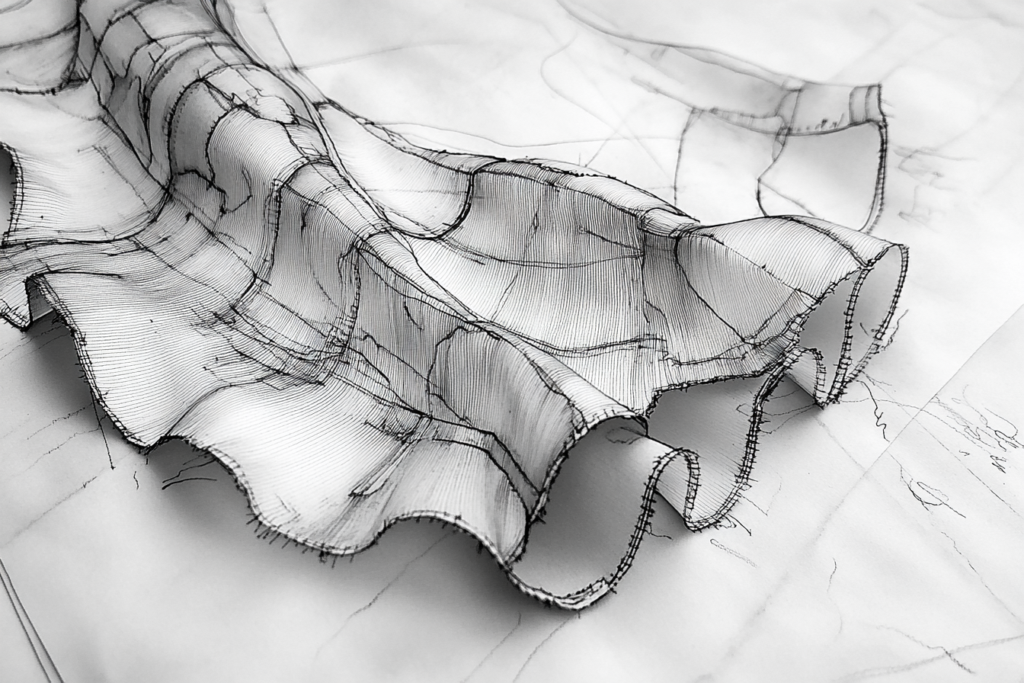

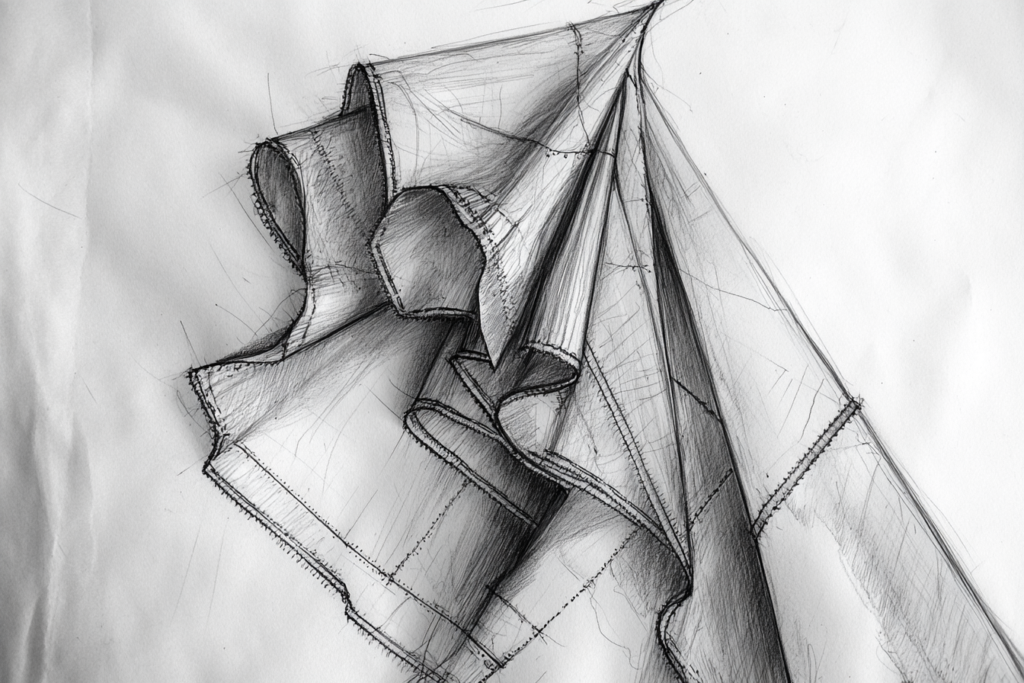

Illustration of a Superimposed Seam

Here’s an illustration showing a superimposed seam where two fabric pieces are overlapped at one end, with the edges neatly stacked and sewn. This method ensures a clean, strong finish for the garment.

Here is the illustration of a superimposed seam (SS), showing how two fabric pieces are overlapped at the edges and sewn together for a clean, strong finish.

Seam Types in Garment Construction

Seams are the foundation of any garment, providing both structure and functionality. There are various types of seams used in garment construction, each serving a different purpose and adding specific qualities to the final garment. Below are some common seam types and their applications:

1. Superimposed Seam (SS)

- Description: A superimposed seam involves overlapping fabric pieces and stitching them together with aligned edges. This seam type is commonly used in outerwear, jackets, and coats where strength is important.

- Use: Provides a strong finish and is ideal for high-stress areas like side seams, armholes, and waistlines.

- Example: Often used in denim, blazers, or sportswear.

2. French Seam

- Description: A French seam encloses the raw edges of the fabric within itself, making it a clean and neat seam. It involves sewing the fabric pieces with the wrong sides together initially, then flipping and stitching again to enclose the raw edges.

- Use: Delicate fabrics like silk, chiffon, and lightweight cotton where raw edges need to be hidden.

- Example: Common in lingerie, blouses, and wedding dresses.

3. Flat-Felled Seam

- Description: A flat-felled seam is a strong, durable seam where the raw edges of the fabric are folded over and stitched down, often used in denim and heavy fabrics.

- Use: Ideal for heavy-duty clothing or items that need extra reinforcement, such as workwear and jeans.

- Example: Common in jeans, cargo pants, and outdoor jackets.

4. Overlock Seam (Serger Seam)

- Description: This seam is created using an overlocker machine (serger), which trims the fabric edge and encloses it in one continuous stitch. It is commonly used to prevent fraying and is fast and efficient.

- Use: Widely used for stretch fabrics and casual wear as it provides a clean, professional finish with minimal fraying.

- Example: Found in knit garments, activewear, and t-shirts.

5. Butt Seam

- Description: A butt seam joins two pieces of fabric by aligning the raw edges together and stitching them. This seam is often used when no visible seam allowance is required.

- Use: Ideal for fabrics that are neat on both sides or for areas that do not require heavy construction.

- Example: Found in fine tailoring, specialty garments, or minimalist designs.

6. Bound Seam

- Description: A bound seam involves wrapping the raw edges of a seam with fabric binding. This creates a clean finish and is often used in tailoring and high-quality garments.

- Use: Used for neat finishes in areas where the seams are visible, such as inside jackets, lining, or waistbands.

- Example: Common in custom-made garments and luxury designs.

7. Lapped Seam

- Description: A lapped seam is created by lapping the edges of the fabric over each other and sewing them down. It is often used in sporting apparel and workwear.

- Use: Ideal for garments requiring flexibility and strength, such as sportswear and uniforms.

- Example: Seen in sweatshirts, sports jackets, and activewear.

Choosing the Right Seam for Your Garment

When selecting a seam type, consider the following factors:

- Fabric type: Some seams work better with lightweight fabrics, while others are better for heavy-duty textiles.

- Garment purpose: Think about whether the garment requires strength (workwear, outerwear) or delicate finishes (wedding dresses, blouses).

- Durability: Some seams, like the flat-felled seam, are designed for garments that undergo frequent wear and washing.

Each seam type offers its own unique advantages, and understanding when and where to use them will help ensure that your garment is well-constructed and long-lasting.

Conclusion: The Practicality and Elegance of the Superimposed Seam

The superimposed seam (SS) is an efficient and durable technique used to join fabric layers together. By overlapping fabric edges and sewing them securely, this method ensures that garments are durable, strong, and have a neat, professional finish. Its use in high-stress areas and in garments requiring extra structure and flexibility makes it indispensable in both fashion and industrial garment manufacturing.

Whether you are creating outerwear, activewear, or casual clothing, mastering the superimposed seam technique will ensure that your garments are well-constructed and built to last.