Technical Back: Understanding the Reverse Side of the Plain Stitch

Meta Description: The technical back refers to the reverse side of a fabric woven with the plain stitch. Learn how the technical back differs from the technical face and its impact on fabric quality and appearance.

What is the Technical Back?

The technical back of a fabric refers to the reverse side of the fabric woven using the plain stitch (also known as the basic weave or simple weave). While the technical face is the smooth, visible side of the fabric, the technical back is often slightly rougher or less organized, with the warp and weft yarns more exposed.

In a plain stitch fabric, the technical back is typically not meant to be seen in the final product, as it is the side that faces the inside of a garment or the reverse of any home textiles. However, understanding the technical back is important for fabric manufacturers, designers, and textile enthusiasts, as it influences the fabric’s construction and performance.

Key Features of the Technical Back

✔ Rougher Texture: The technical back of a plain stitch fabric is often less smooth than the front, with yarns more visible.

✔ Unfinished Appearance: The back side typically has a less polished appearance, with floating threads and sometimes uneven yarn placement.

✔ Durable: While not as visually appealing as the front, the back is still structurally strong and can withstand wear.

✔ Hidden from View: In most garments, the technical back is hidden inside, but it can occasionally be used in certain designs like reversible fabrics or unfinished looks.

How the Technical Back Differs from the Technical Face

| Feature | Technical Face | Technical Back |

|---|---|---|

| Appearance | Smooth, even surface | Rougher, uneven surface |

| Thread Visibility | Evenly woven threads | Threads may float or show more |

| Use | Visible side of the fabric | Hidden side of the fabric |

| Texture | Flat and polished | Slightly textured |

| Functionality | Used for aesthetics | Used for durability and structure |

The technical face is generally the preferred side for aesthetic purposes, while the technical back provides the structural integrity needed for the fabric.

How Plain Stitch Forms the Technical Back

In a plain weave, the warp threads (the vertical threads) alternate over and under the weft threads (the horizontal threads). This simple interlacing creates a strong, balanced fabric. On the technical back, the interlacing can result in exposed yarns, and there may be slight unevenness in the placement of threads.

- The front side of the fabric (technical face) shows an even pattern, while the back shows the reverse interlacing of the threads.

- The technical back may also display floating threads where the weft yarns are not tightly interwoven, leading to an irregular surface.

Applications of the Technical Back

The technical back is typically not visible in most garments but still plays an essential role in fabric construction. Here’s how it impacts various textile applications:

📌 Shirts and Casual Clothing

- The technical back of plain weave fabrics is usually hidden inside garments like shirts, blouses, and casual wear.

📌 Upholstery Fabrics

- For upholstered furniture, the technical back may not be visible but contributes to the durability and strength of the fabric.

📌 Reversible Fabrics

- Some designs use the technical back as part of the reversible design, where both sides of the fabric are meant to be exposed.

📌 Home Textiles

- Bed linens, tablecloths, and curtains may use the technical back in areas where durability is needed, like on the inside or the underside of the fabric.

Advantages of the Technical Back

1. Durability and Strength

The technical back contributes to the structural integrity of the fabric. The rougher texture and tight interlacing of threads ensure the fabric holds together well and resists wear and tear.

2. Cost-Effectiveness

Since the technical back is not visible in most garments, designers often focus on creating high-quality, aesthetically pleasing technical faces, while the back side remains simple and functional. This helps in cost-efficient production.

3. Enhanced Comfort

In garments where the technical back is used (like reversible fabrics or unfinished seams), it may provide additional comfort by offering a softer or more flexible side for wear.

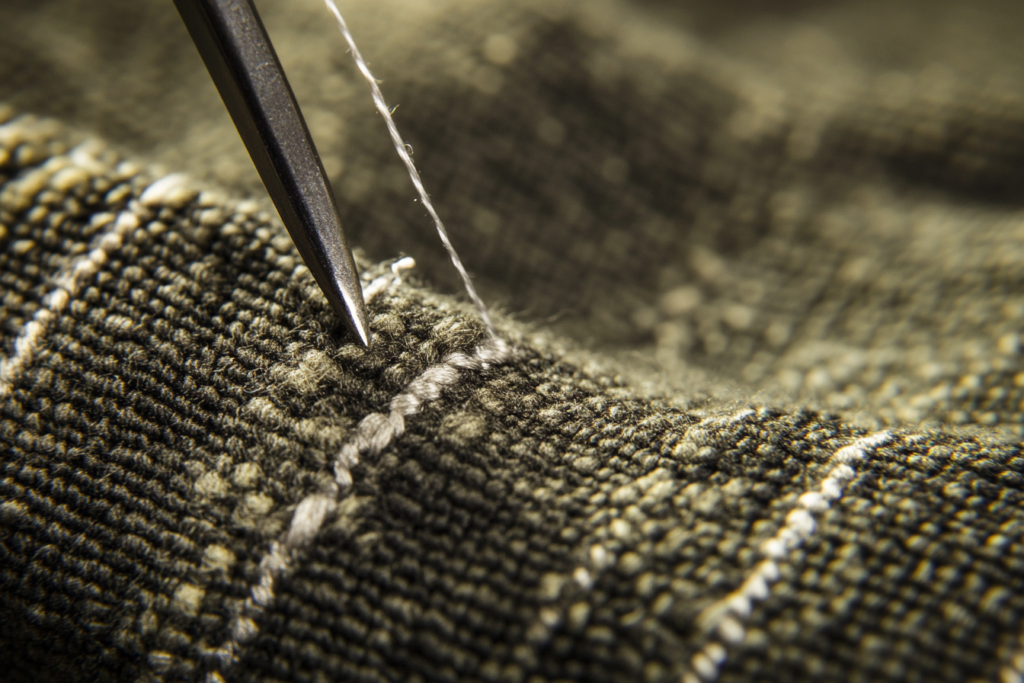

Illustration of the Technical Back of Plain Stitch Fabric

Below is an illustration showing the technical back of a fabric woven using the plain stitch. It highlights the rougher, uneven surface of the back side, showing how the threads are interwoven and sometimes float freely, creating a more textured appearance compared to the smooth front side of the fabric.

Conclusion: The Importance of the Technical Back in Plain Stitch Fabrics

The technical back is an essential part of the plain stitch fabric, contributing to the structure and strength of the textile. While not typically seen, the back side ensures that the fabric is durable, strong, and functional.

Understanding the technical back and how it contrasts with the technical face is key for fabric manufacturers and designers. It helps ensure that garments and textiles are made from fabrics that are not only visually appealing but also functional and long-lasting.