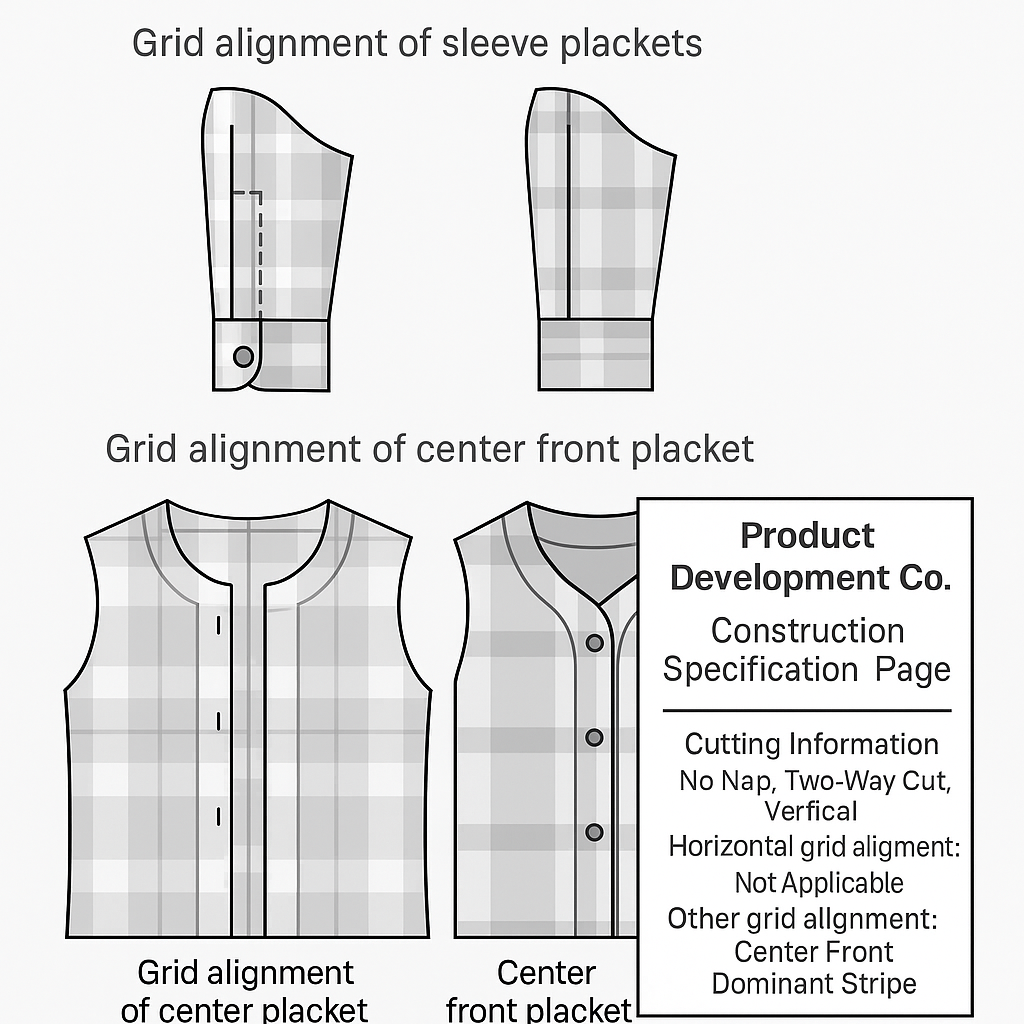

Grid Alignment in Plaid Garments: Sleeve Slits and Center Front Plackets

In fashion design and garment manufacturing, grid alignment in plaid fabrics is a critical quality marker. Even minor misalignments can visibly disrupt the overall aesthetics of a plaid garment. Two specific areas that require extra attention are sleeve slits and the center front placket. Aligning the plaid grid at these construction points enhances the visual appeal and communicates craftsmanship and quality to discerning consumers.

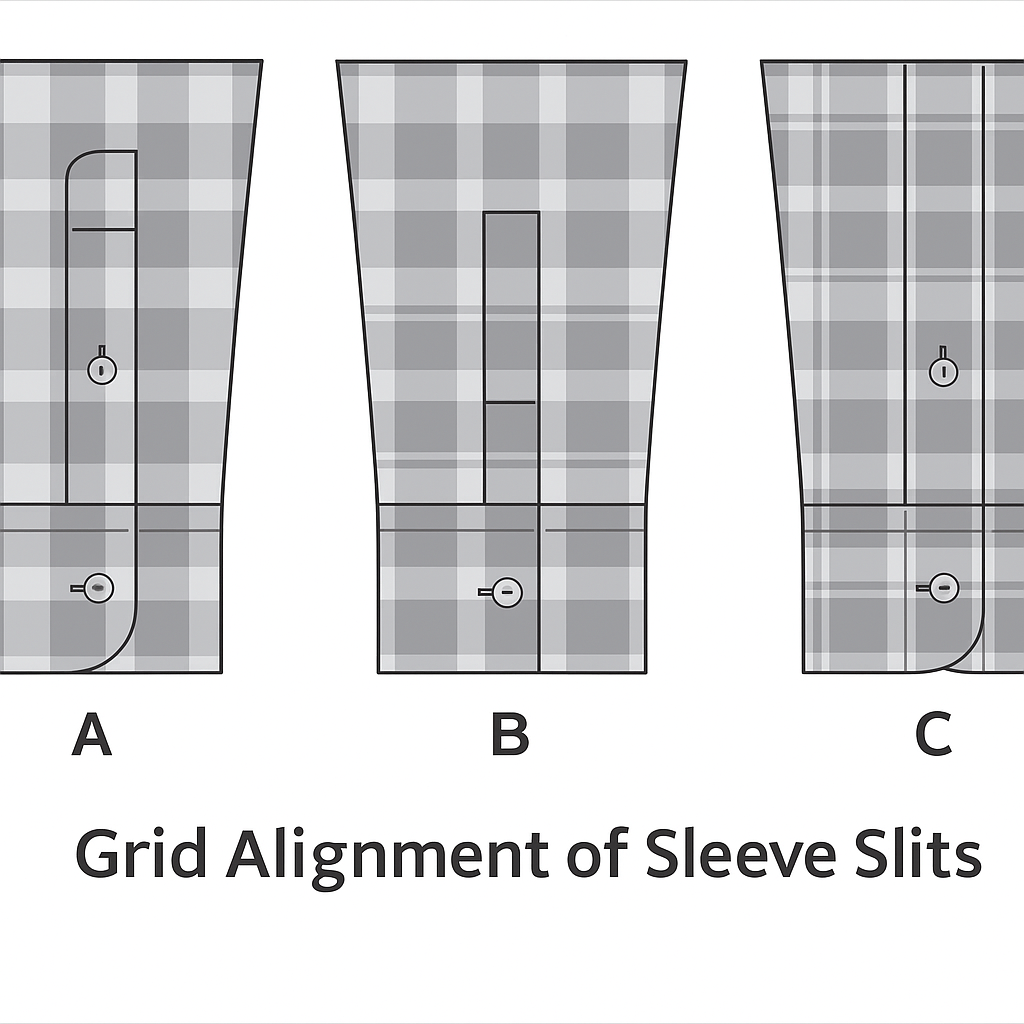

Sleeve Slit Grid Alignment

Sleeve slits—especially on men’s woven shirts—are small but prominent features where plaid matching is highly visible. Three primary approaches to grid alignment are used in industry practice:

- Figure A: No Grid Matching

The sleeve slit does not align with any grid lines. This method is quicker but often results in a disjointed visual, especially in bold or large plaids. - Figure B: Horizontal Grid Alignment Only

The sleeve slit aligns horizontally but not vertically. This is the most commonly accepted practice in mid-range shirts, striking a balance between aesthetics and cost. - Figure C: Full Horizontal and Vertical Grid Alignment

This premium approach ensures the grid matches both horizontally and vertically across the slit. It is the gold standard for luxury shirting and tailored garments.

Takeaway: The choice of alignment method should reflect the garment’s intended price point and quality level. Higher alignment accuracy requires more fabric and careful cutting, raising production costs.

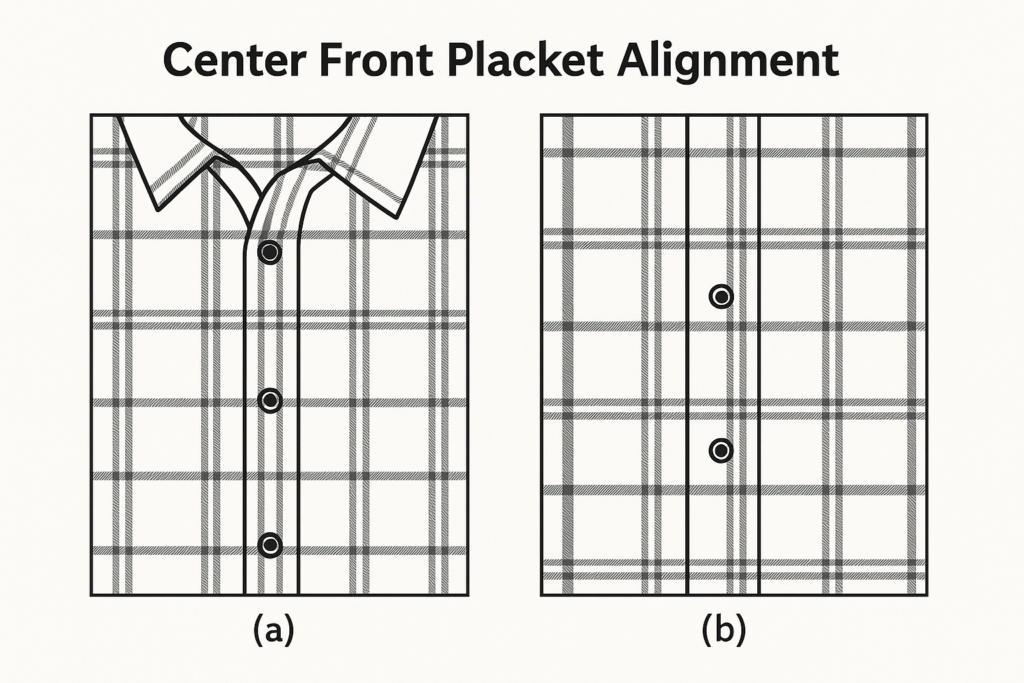

Center Front Placket Alignment

The center front placket is the most visually dominant part of a plaid shirt. Misalignment here is immediately noticeable.

- Figure A: Placket with Seam

This design includes a seam that must be perfectly aligned with the shirt body’s grid. It introduces an extra point of potential misalignment and therefore requires careful attention during cutting and sewing. - Figure B: Open Stitch Placket (No Seam)

This version eliminates the seam, reducing complexity and grid disruption. It typically appears neater but has fewer styling options.

Design Tip: When a center front seam is present, ensure the dominant vertical stripe aligns with the shirt body to create symmetry.

Construction Notes & Best Practices

Garment factories must follow clear construction documentation to achieve alignment. Below is an example of a professional worksheet from a development company:

📄 Product Development Company – Construction Description Page

- Cutting Information: No fluff, two-way cutting, vertical

- Horizontal Grid Alignment: Front panel, side seams

- Vertical Grid Alignment: Not applicable

- Other Grid Alignment: Center front dominant stripe

Why Grid Alignment Matters

| Feature | Without Grid Alignment | With Grid Alignment |

|---|---|---|

| Visual Symmetry | Asymmetrical, unbalanced | Clean and tailored |

| Brand Perception | Low to mid-range | High-quality and premium |

| Production Cost | Lower | Higher due to fabric waste and labor |

| Customer Satisfaction | May go unnoticed | Enhances visual impact and appeal |