Cutting Technique Design: Balancing Aesthetic and Cost

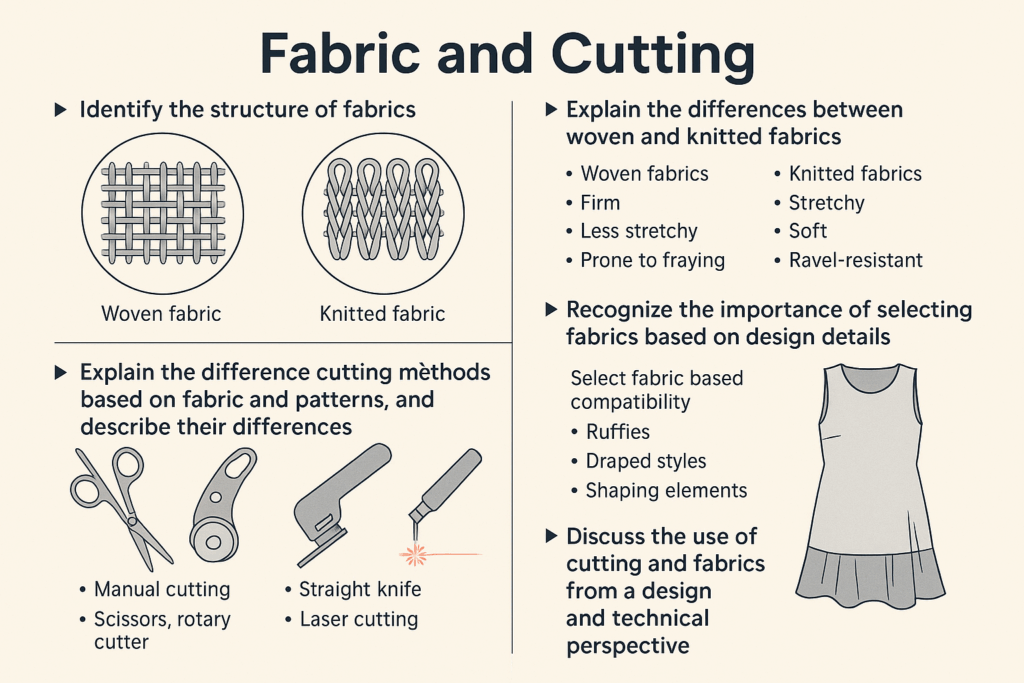

In garment manufacturing, the cutting technique plays a critical role in determining both the final look of the product and the overall production cost. Designers must make intentional decisions about how to cut fabric to maximize visual appeal, maintain garment quality, and control expenses. This is especially crucial when it comes to detailed features like patch pockets, plackets, and aligned elements in plaid or striped fabrics.

✂️ Why Cutting Techniques Matter

Cutting is more than just slicing fabric into shapes. It’s a strategic process influenced by:

- Fabric characteristics (print, plaid, nap)

- Garment construction details (pockets, cuffs, linings)

- Desired visual effects (alignment, symmetry)

- Budget constraints

Failing to optimize cutting can result in mismatched patterns, fabric waste, or increased labor time—all of which add cost without improving quality.

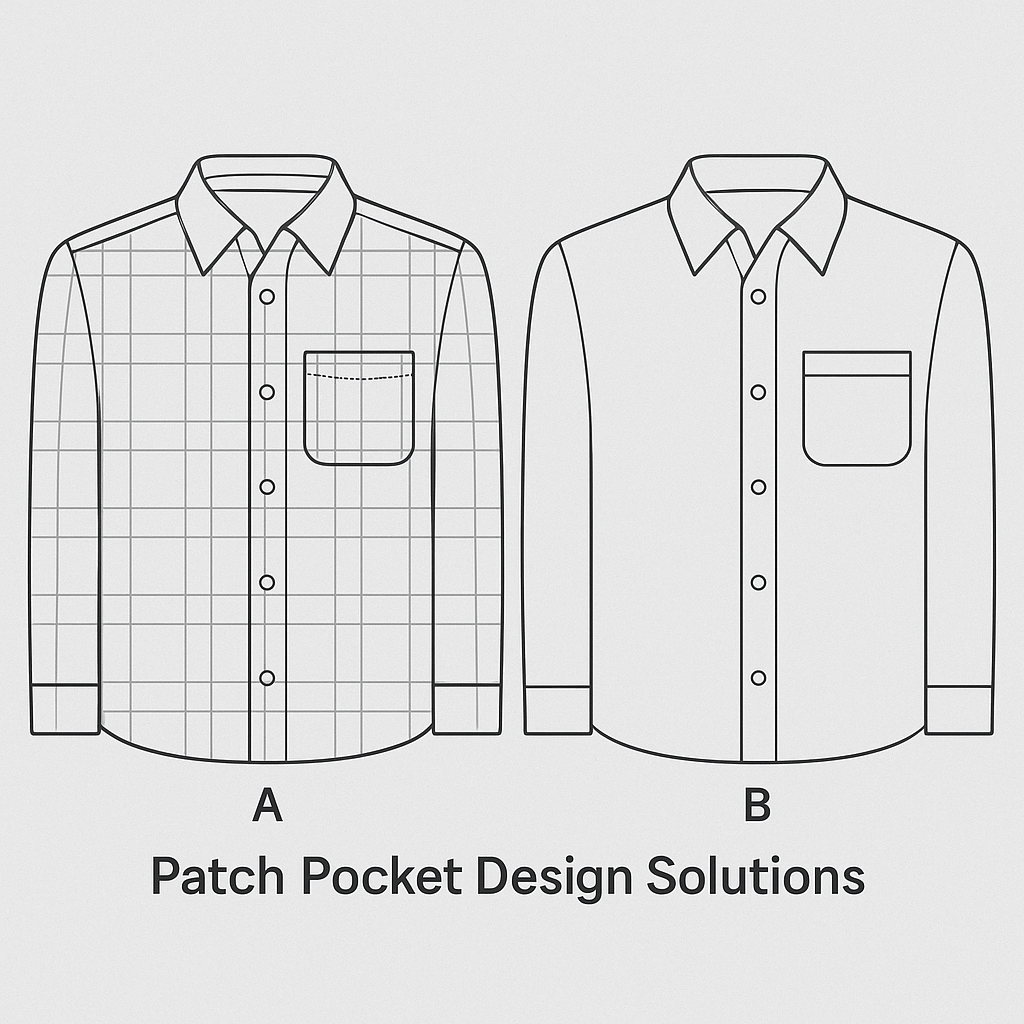

🧵 Patch Pocket Design: A Case Study

Let’s take patch pockets as a key example. A designer may envision a patch pocket that visually integrates with the shirt’s plaid pattern. To achieve this, the pocket must be aligned both horizontally and vertically, which requires additional fabric and precise placement during cutting.

🔹 Option 1: Aligned Patch Pocket (Figure A)

- Pros: Clean visual integration with fabric pattern

- Cons: More fabric waste, higher labor time for alignment

- Application: Premium shirts, fashion-forward brands

🔹 Option 2: Welt Pocket with Seams (Figure B)

- Pros: Eliminates the need for alignment, reduces waste

- Cons: Visual separation from pattern, requires a different sewing technique

- Application: Mid-range to budget-conscious apparel

Despite their differences, both methods achieve a similar functional outcome. The choice depends on how much value the brand places on aesthetics versus cost-efficiency.

📐 Design Decision-Making for Cost Control

To align design with cost targets, consider the following:

- Prioritize alignment for key visual areas (e.g., chest, collar, center front).

- Use functional alternatives (like welt openings) when alignment is cost-prohibitive.

- Communicate clearly with the factory—specify which details require alignment and which can be relaxed.

- Include marking instructions early in the tech pack or process sheet.

💡 Pro Tip:

Alignment adds both fabric usage and cutting time. If the fabric is expensive or the order quantity is high, even small efficiency gains can lead to substantial savings.

👚 When to Choose Function Over Form

Not every garment needs perfect pattern matching. For instance:

- Basic shirts can use welt pockets to cut cost.

- Checkered children’s wear may skip alignment altogether.

- Workwear often favors durability over pattern aesthetics.

Ultimately, cutting technique design is about smart trade-offs that suit the garment’s purpose and price point.