EF (Edge Finishes): A Guide to Edge Treatment in Garment Construction

Edge Finishes (EF) are stitching methods used to complete single-layer fabric edges. Explore types of edge finishes like hems, welts, piping, plackets, and more for clean, professional garments.

🔍 What is EF (Edge Finishes)?

EF, short for Edge Finishes, refers to a group of stitching techniques specifically designed to finish single-layer fabric edges in garment construction. These finishes are applied to visible edges of a garment to prevent fraying, maintain structure, and improve the aesthetic quality of the finished piece.

These techniques are essential for achieving a professional appearance and long-term durability, especially at stress points such as hems, cuffs, waistbands, and plackets.

✅ Edge finishes are not just decorative—they’re functional and structural.

🧵 When Are Edge Finishes Applied?

Edge finishes are typically applied:

- 📌 Before or after garment assembly

- 📌 On exposed single-layer edges

- 📌 On lightweight to medium-weight fabrics

- 📌 To enhance appearance or improve durability

They are especially important in garments where the interior construction is visible or the fabric is prone to fraying.

📚 Edge Finishes Covered in This Guide (EF Types)

Here’s a breakdown of the most common EF types used in modern garment making:

| EF Type | Description | Common Use |

|---|---|---|

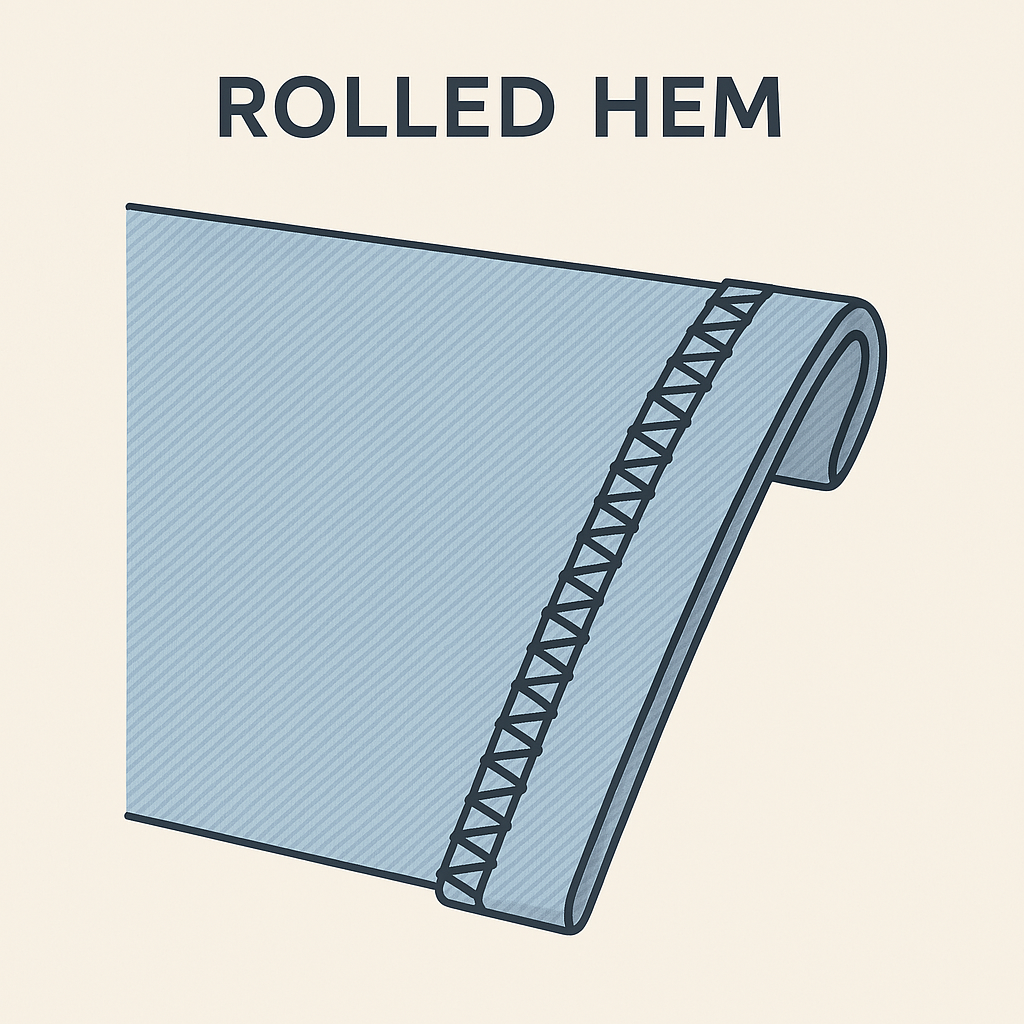

| Hems | Folded fabric edge secured with a line of stitching | Shirts, dresses, trousers |

| Strips & Belts | Narrow fabric pieces applied as edging or decoration | Waistbands, decorative trims |

| Tunnel Elastic | A casing that holds elastic between layers of fabric | Waistbands, sleeve cuffs |

| Piping | Cord enclosed in fabric and sewn into seams or edges | Collars, cushions, decorative clothing |

| Welts | A folded strip of fabric sewn to a garment edge | Pocket openings, front openings |

| Placket Cuffs | A slit and overlapping strip, often finished with buttons | Shirt sleeves, tunic necklines |

| Cuffs/Trims | Finished edge details around sleeves or pant legs | Shirt cuffs, pant hems |

✂️ Why Are Edge Finishes Important?

📌 1. Prevent Fraying

EF techniques seal the edge of the fabric, preventing unraveling, especially in woven fabrics.

📌 2. Improve Aesthetic Appeal

A cleanly finished edge elevates the professional look of the garment—no raw edges or loose threads.

📌 3. Add Strength & Shape

Edge finishes reinforce high-stress areas like pockets, collars, and plackets, helping garments hold their shape.

📌 4. Increase Comfort

EF can smooth or soften edges, reducing discomfort where the garment touches the skin.

📐 Edge Finishes in Practice: Where to Use Each Type

| Garment Area | Suggested EF Method |

|---|---|

| 👕 Hemline | Folded hem, blind hem |

| 👖 Trouser cuffs | Turned-up cuff, tunnel elastic |

| 👚 Sleeve cuffs | Placket cuff, bias bound |

| 🧥 Pocket openings | Welt, piping |

| 🎽 Necklines | Piping, bias facing |

| 🩳 Waistbands | Tunnel elastic, faced band |

📌 Tips for Successful Edge Finishes

- Always press the edge before and after stitching for a neat finish.

- Choose EF types based on fabric weight and garment function.

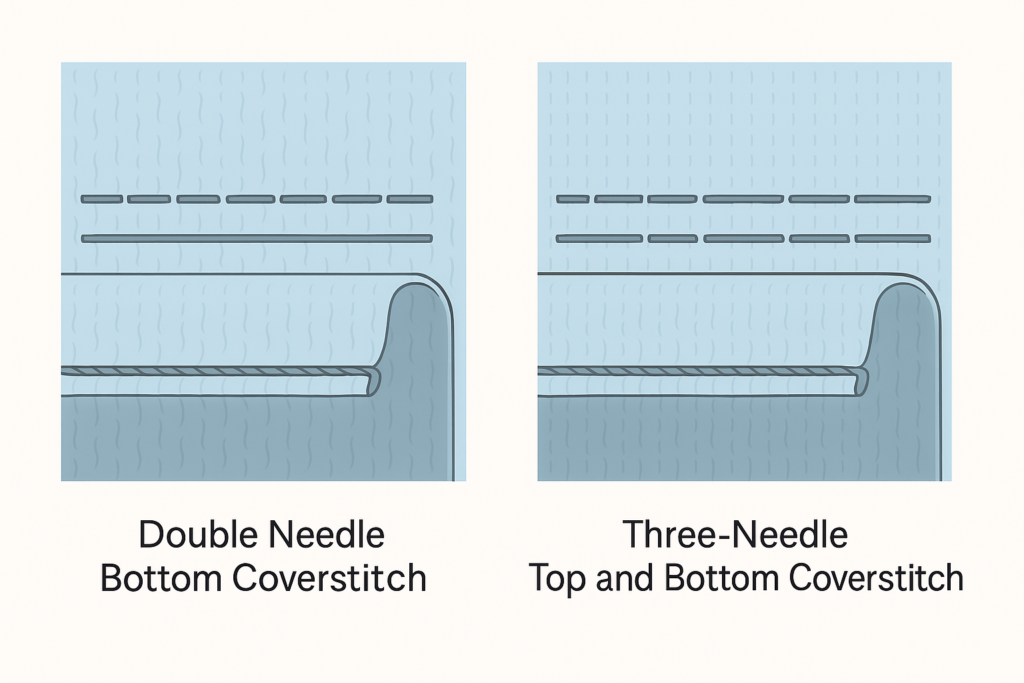

- For stretch fabrics, use EF methods like tunnel elastic or coverstitch hems.

- Use interfacing in plackets or welts for better shape retention.

🖼️ Illustration of Edge Finishes Types

Here’s a visual example of various EF applications, including hems, piping, welts, and placket cuffs.

Note: This image represents similar edge reinforcement techniques; a full EF-specific diagram can follow.

🧶 The Role of Edge Finishes in Quality Garment Making

EF (Edge Finishes) are more than just details—they are essential techniques that blend function and design. Whether you’re reinforcing a hem, adding comfort to a waistband, or enhancing the beauty of a neckline, the right edge finish ensures a garment that’s not only stylish but also long-lasting.