Heat-Cut Edges in Fabric Finishing: Techniques, Applications & Advantages

🔥 What Are Heat-Cut Edges?

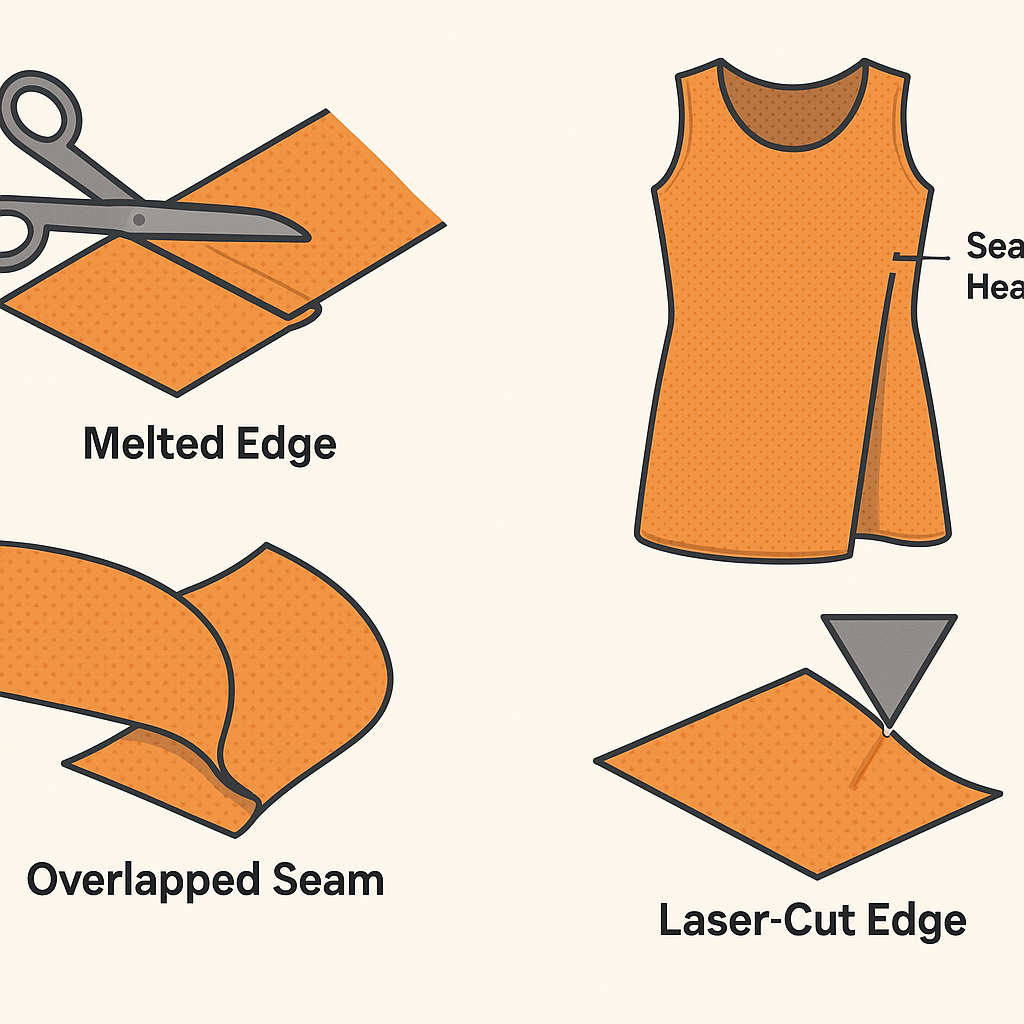

Heat-cutting is a fabric edge finishing technique that uses heat to melt the edges of synthetic fibers—like nylon and polyester—to prevent fraying and unraveling. This method is especially useful for fabrics with low melting points, producing clean, sealed edges without the need for additional stitching or binding.

Heat-cutting can be used in both manual and automated applications—from heat scissors to laser-cutting machines—to achieve durable, maintenance-free edges.

✂️ How Heat-Cut Edge Finishing Works

🔸 Heated Scissors / Hot Knife

- Melts synthetic fibers like nylon, polyester, or acetate while cutting

- Seals the edge simultaneously, preventing fraying

- Commonly used for clothing labels, ribbons, and flags

🔸 Laser-Cut Edges

- High-precision lasers cut and melt edges in a single pass

- Useful for complex curves and fine detailing

- The edges bond during cutting, eliminating the need for stitching

- Popular in technical textiles, decorative overlays, and performance wear

🧷 Best used on thermoplastic synthetic fabrics that melt cleanly instead of burning.

🧥 Application Example: Transparent Nylon Dress

- A vintage dress made of sheer nylon

- Seam allowances were heat-cut, providing a clean, fused edge

- Ensures long-term durability—edges remain smooth and unchanged for decades

- Ideal for preserving delicate, transparent fabrics without bulky seam finishes

⚙️ Where Heat-Cut Edges Are Commonly Used

| Application Area | Heat-Cut Method | Fabric Type | Purpose/Benefit | Additional Notes |

|---|---|---|---|---|

| Clothing Labels | Hot Knife / Laser | Nylon / Polyester | Sealed edges, no fraying | Easy to apply during production |

| Transparent Garments | Heated Scissors | Sheer Nylon | Prevents fraying, keeps fabric clear | Preserves appearance long-term |

| Irregular Seams | Heat Cut + Overlap | Lightweight synthetics | Time-saving, no edge treatment needed | Especially good for curves (Figure 10.19) |

| Flags & Kites | Hot Knife | Nylon Ripstop | Wind-resistant, sealed edges | Lightweight performance textiles |

| Decorative Badges | Laser-Cut Edge | Woven Polyester | Smooth, bonded cut | Often used in embroidery patches |

🧵 Advantages of Heat-Cut Edging

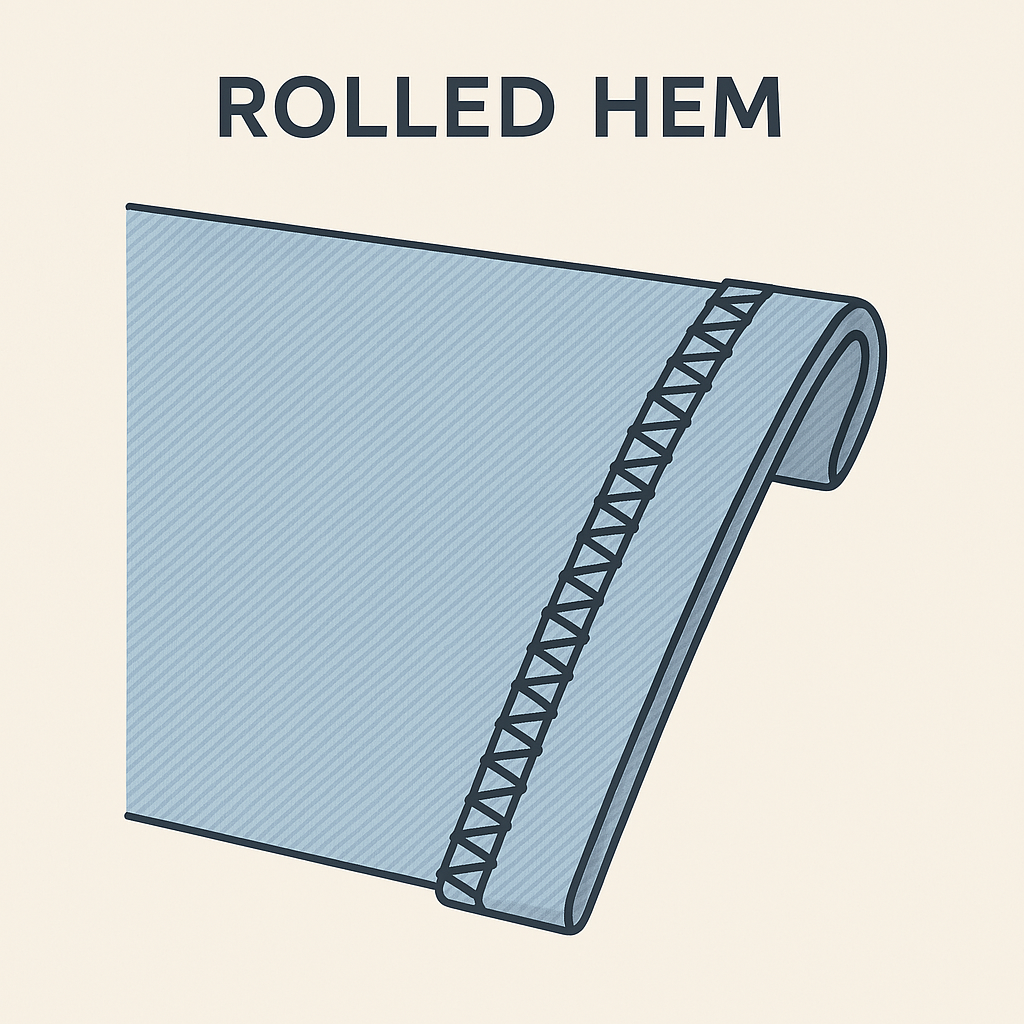

✔️ Prevents fabric from fraying without sewing

✔️ Clean, smooth finish with no seam allowance bulk

✔️ Ideal for curved or complex edge shapes

✔️ Long-lasting, non-degrading sealed edges

✔️ Reduces production time for synthetic garments and accessories

⚠️ Limitations and Considerations

- Only suitable for synthetic fabrics like nylon, polyester, acetate

- Not recommended for natural fibers like cotton or wool

- Requires special equipment (heat knife, laser cutter)

- May discolor light-colored fabrics if overheated

- Not ideal for visible seams in luxury garments

📌 Summary

Heat-cut edges provide a fast, efficient, and clean solution for edge finishing on synthetic fabrics. Whether applied manually with heated scissors or precisely by laser, the method offers fray-free seams, clean curves, and long-term durability—ideal for garments like sheer dresses, technical sportswear, and accessories such as labels or patches. When used appropriately, heat-cutting can dramatically reduce sewing time and enhance garment performance.