Piping in Garment Construction: Decorative and Functional Edge Finishing

🧵 What Is Piping?

Piping is a decorative and functional edge finish that wraps raw edges using a fabric strip, often cut on the bias to handle curves. It is especially common in collars, waistbands, hems, plackets, and armholes—primarily in knitwear, woven garments, and children’s clothing.

Piping may be made from woven, ribbed, or elastic fabric, and sewn using various stitch techniques, such as double needle, chain stitch, blind stitch, or Z-stitch.

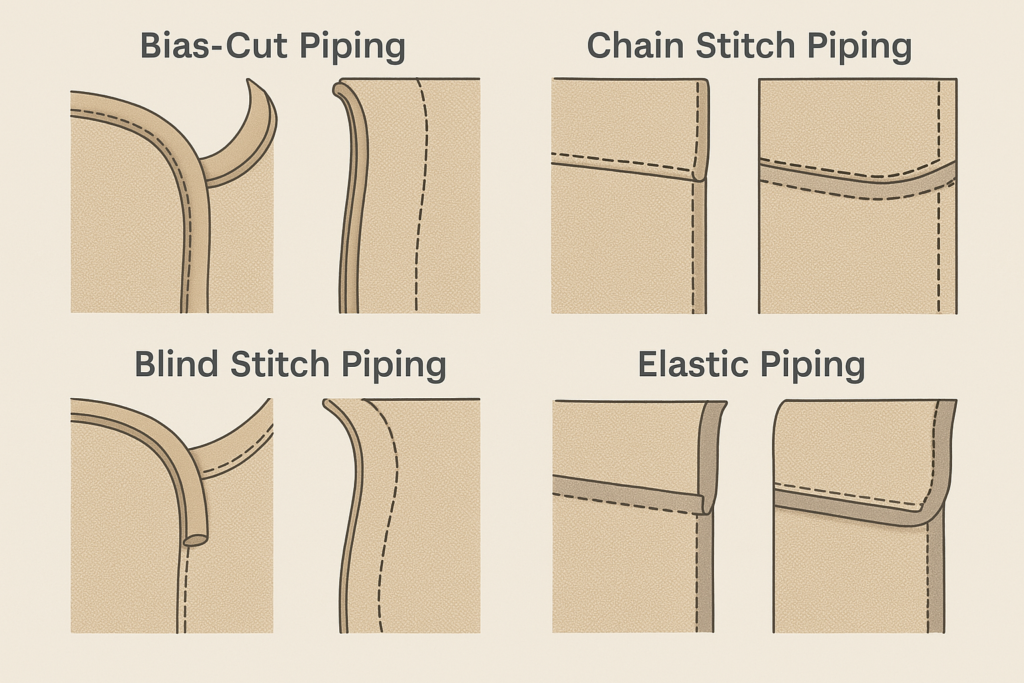

📐 Piping Construction Techniques

🔸 Bias-Cut Double-Fold Piping

- Used on collars and curves for a clean finish

- Cut on the bias to conform to round edges

- Can be pre-folded and pressed (store-bought or handmade)

🔸 Chain Stitch Piping

- Long pre-cut strips are attached with a seam stacker

- Sewn using a chain stitch machine, ideal for bulk production

🔸 Double Needle Stretch Stitch

- Best for knitted garments or stretch piping

- Ensures strong hold while maintaining elasticity

🔸 Ribbed Knit Piping

- Used for comfortable, elastic edge finishing

- Common in casualwear and sportswear collars

🪡 Special Stitching Styles for Piping

🔹 Blind Stitching or Drop Needle

- Stitch is sewn between piping and garment, remaining invisible from the outside

- Suitable for formal garments or clean design finishes

🔹 Single-Stitch Piping

- A minimal approach used for woven garments, plackets, or internal waistband edges

- Uses bias-cut strips for flexibility and fit

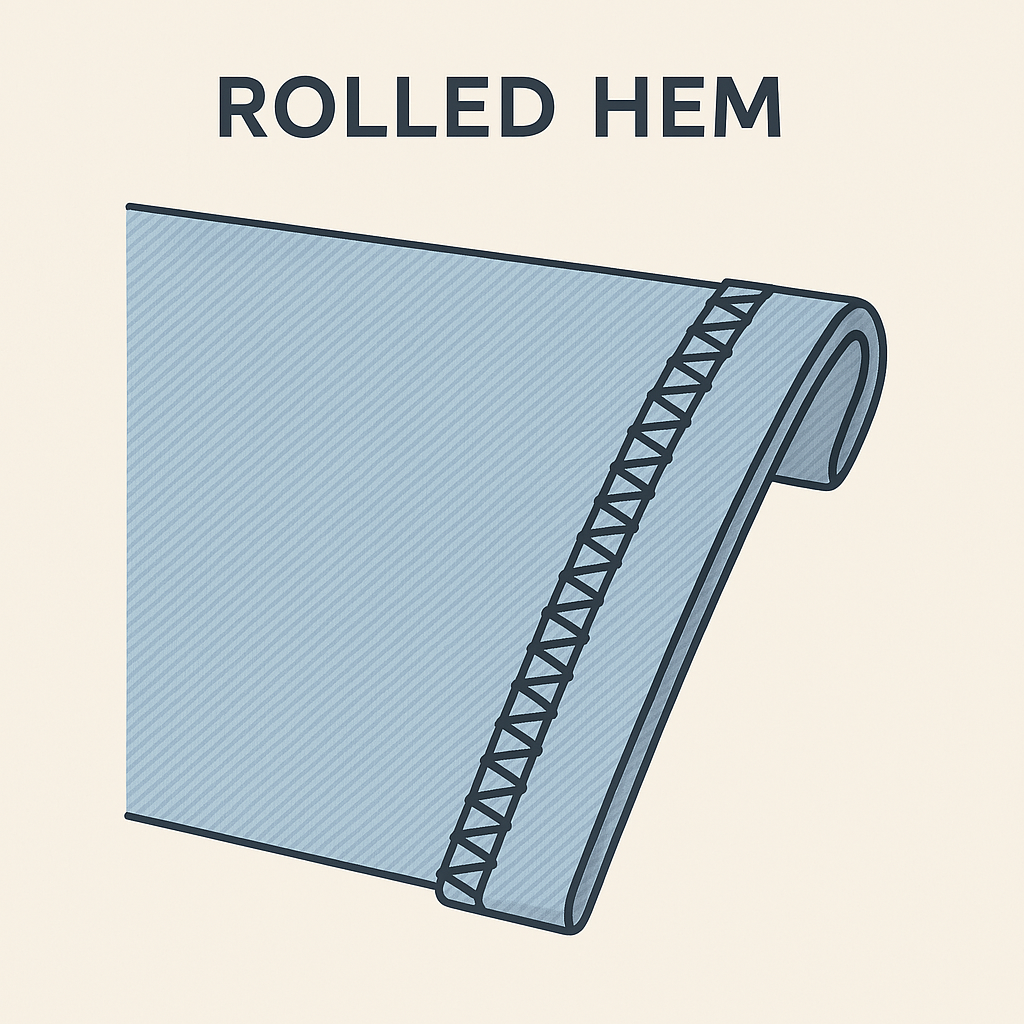

🧵 Piping on Hems, Straps & Bibs

🔸 Tape or Ribbon Piping

- Used for hem finishing, especially where folding seam allowances isn’t ideal

- Three layers are stacked to reduce seam thickness

🔸 Shoulder Strap Piping

- Applied to vests and women’s tops for edge decoration and shape

🔸 Piping Without Edge Treatment

- Suitable only for very thin fabrics to avoid bulk when using five fabric layers

🔸 Decorative Piping for Bibs

- Two types of bias yarn applied via folding machine or double needle stitch

- Edges are folded over and visibly stitched

🧵 Elastic Piping in Stretch Garments

🔸 Elastic Knit Piping

- Pre-finished piping applied without folding inward

- Thin, lightweight, and stretch-compatible

- Common in women’s underwear, knit tanks, and intimates

- Sewn with a “Z” stitch that stretches with the garment

👗 Garment Use Table for Piping

| Application Area | Piping Type | Stitch Method | Fabric Type | Notes |

|---|---|---|---|---|

| Knit Collars | Elastic or Ribbed | Double Needle Stretch | Jersey, Rib Knit | Flat, elastic finish |

| Woven Shirt Plackets | Bias Piping | Blind Stitch / Chain | Poplin, Cotton | Neat, hidden seam |

| Baby Bib Edges | Bias Yarn Piping | Visible Double Stitch | Terry, Woven Cotton | Decorative, high quality |

| Vest Shoulder Straps | Ribbed or Elastic Piping | Chain or Z Stitch | Knit or Stretch Woven | Adds stretch and shape |

| Waistband Interior | Single Stitch Piping | Straight Stitch | Woven | Functional seam clean-up |

| Underwear Leg Openings | Elastic Piping | Z Stitch | Nylon Spandex | Flat, seamless comfort |

🌟 Advantages of Piping in Garments

✔️ Decorative and functional

✔️ Helps define edges and curves

✔️ Offers stretch compatibility for knits

✔️ Reduces seam bulk in multi-layer garments

✔️ Available in pre-folded or custom strips

📌 Summary

Piping is an essential edge-finishing technique in both fashion and utility garments. Whether you’re using bias-cut woven strips or pre-processed elastic piping, it provides a professional look while enhancing seam strength, shape retention, and comfort. From baby bibs and sportswear to delicate necklines and structured hems, piping adds both durability and design.