Other Types of Vents and Cuffs in Garment Construction: Lightweight and Elastic Finishes

🧵 Overview

Vents and cuffs are critical elements in sleeve construction, contributing to both functionality and appearance. For lightweight fabrics, alternative vent methods can simplify production, while elastic cuffs provide comfort and adaptability—especially in children’s wear and casual outerwear.

This article covers low-cost slit techniques, pleated sleeve finishes, and specification methods for elastic cuffs

✂️ Other Types of Vents for Lightweight Fabrics

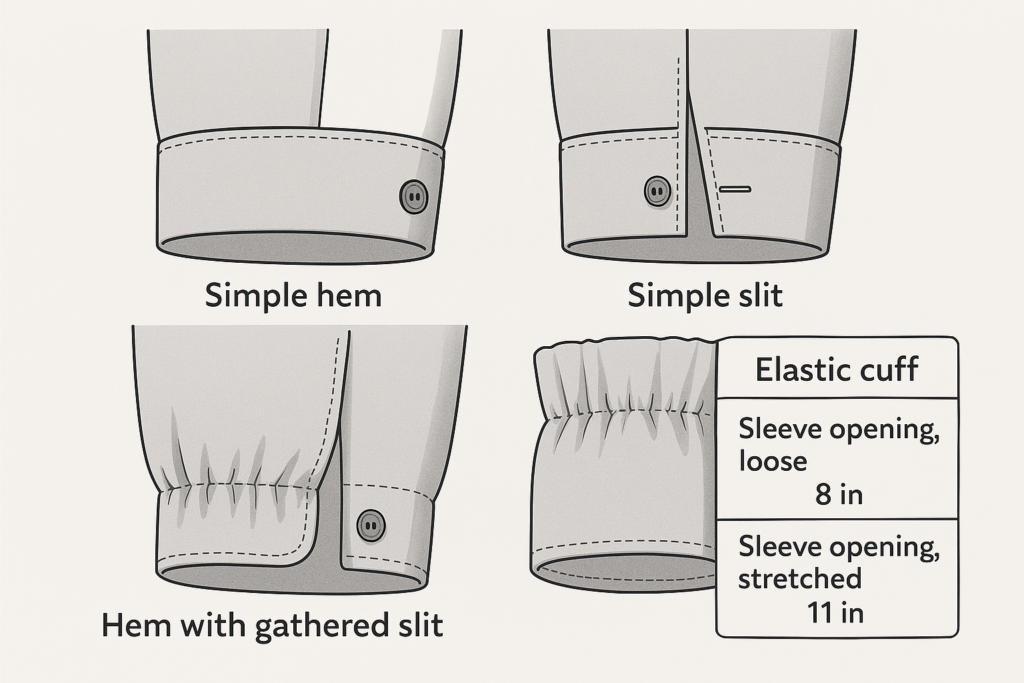

🔸 Sewing Line Vents

- A vent created as a clean seam line, typically at the underside of the sleeve

- Offers a subtle slit opening without extra placket pieces

- Ideal for lightweight, woven fabrics

- Can be paired with buttons, but often avoided at the underside to prevent discomfort when the arm rests on a surface

🔸 Basic Vent with Button Tab

- Simplified slit without additional folds or plackets

- Efficient and suitable for cost-sensitive garments like school uniforms or fast fashion

- Clean inside finishing is essential for comfort and durability

📌 Even basic slits must be carefully dimensioned and recorded in the specification sheet for accurate sampling and sizing.

🌬️ Wrinkle-Gathering Slits for Thin Fabrics

🔸 Slit Gathering Technique

- When sleeve width is generous, it may naturally gather or pleat at the wrist

- Gathering near a slit adds visual interest while conserving cost

- Often used in women’s blouses and light woven tops

🔸 Simplest Slit Finish

- Very low-cost slit treatment with a basic seam and slight backing

- Used in children’s clothing or fluffy woven garments like brushed cotton

- When tied, pleats may form, giving a casual or playful shape

🧷 Elastic Cuffs

- Elastic cuffs are ideal when stretch and ease are needed at the wrist

- Common in children’s shirts, windbreakers, and casualwear

- Eliminates the need for a slit, offering fast construction and flexibility

🧮 How to Specify Elastic Cuffs

In a specification sheet, two critical measurements are used:

| Measurement Name | Description | Example Value |

|---|---|---|

| Sleeve Opening (Loose) | Circumference when elastic is relaxed | 8 inches |

| Sleeve Opening (Stretch) | Maximum circumference when elastic is stretched by hand | 11 inches |

🧷 These values help pattern makers determine cuff width, elastic length, and appropriate sizing across different garment sizes.

👗 Use Table for Vents and Cuffs

| Garment Type | Vent Type | Cuff Type | Best For | Cost Efficiency |

|---|---|---|---|---|

| Light Blouse | Basic seam slit | Hemmed or Tie | Daily wear | ✅✅✅ |

| Children’s Top | Simple cut slit | Elastic cuff | Comfort & play | ✅✅✅ |

| Thin Windbreaker | No slit | Elastic casing | Quick fit, weather wear | ✅✅ |

| Women’s Tunic | Gathered slit vent | Decorative hem | Volume & shape styling | ✅ |

| School Uniform | Under-sleeve vent | Folded cuff | Practical, neat | ✅✅ |

🌟 Key Takeaways

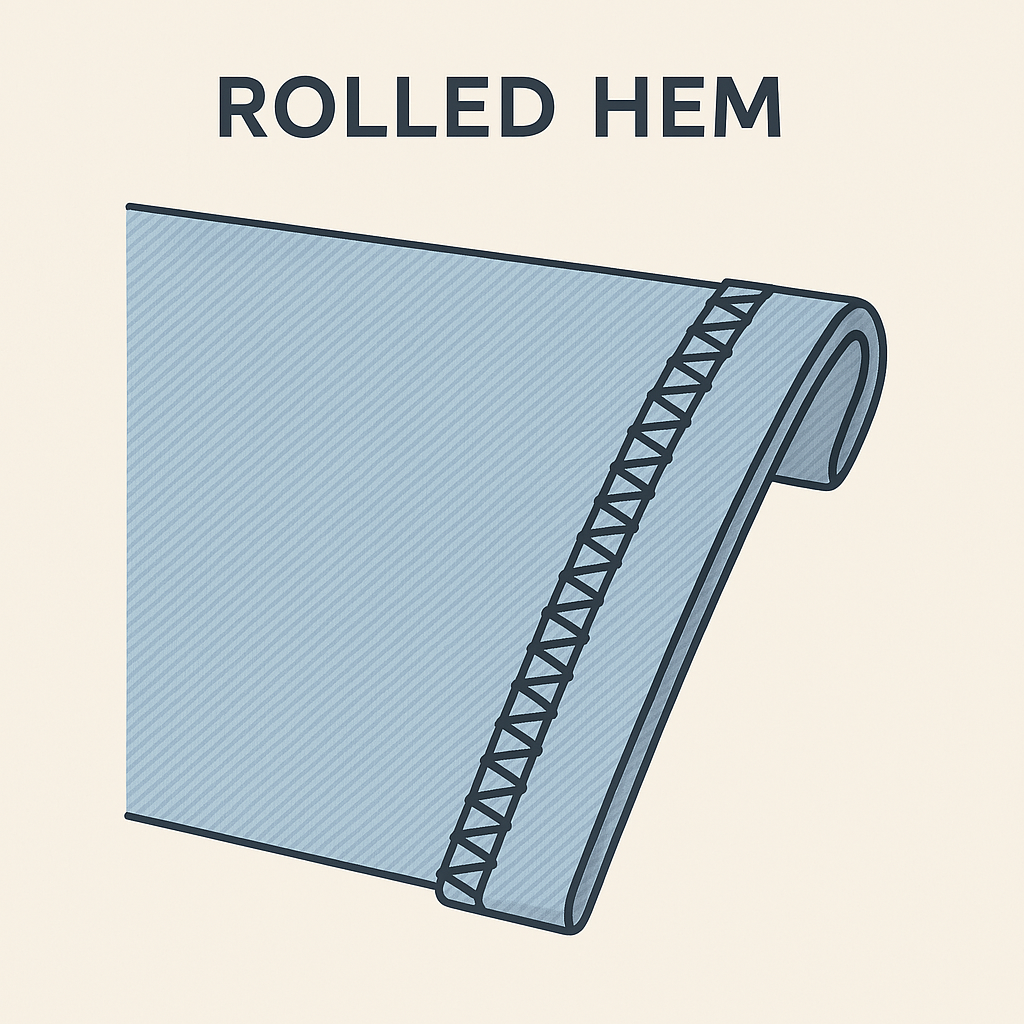

✔️ Simplified vents reduce bulk and cost in lightweight garments

✔️ Elastic cuffs provide comfort and easy dressing, especially for children

✔️ Slit finishing still requires precise measurements and clean stitching

✔️ When done correctly, these methods balance efficiency and design intent

✔️ Proper spec sheet details are vital for repeatable, quality production

📌 Summary

In lightweight garments, vent and cuff designs must strike a balance between function, comfort, and cost. From stitched slit vents to gathered sleeve finishes and elastic cuffs, these construction methods offer manufacturers versatile, low-bulk solutions. Whether creating a casual blouse or a school uniform, early attention to sizing specifications and finishing techniques ensures a consistent, quality garment.