🧵 Ribbed Fabric in Fashion: Structure, Benefits, and Applications

Introduction

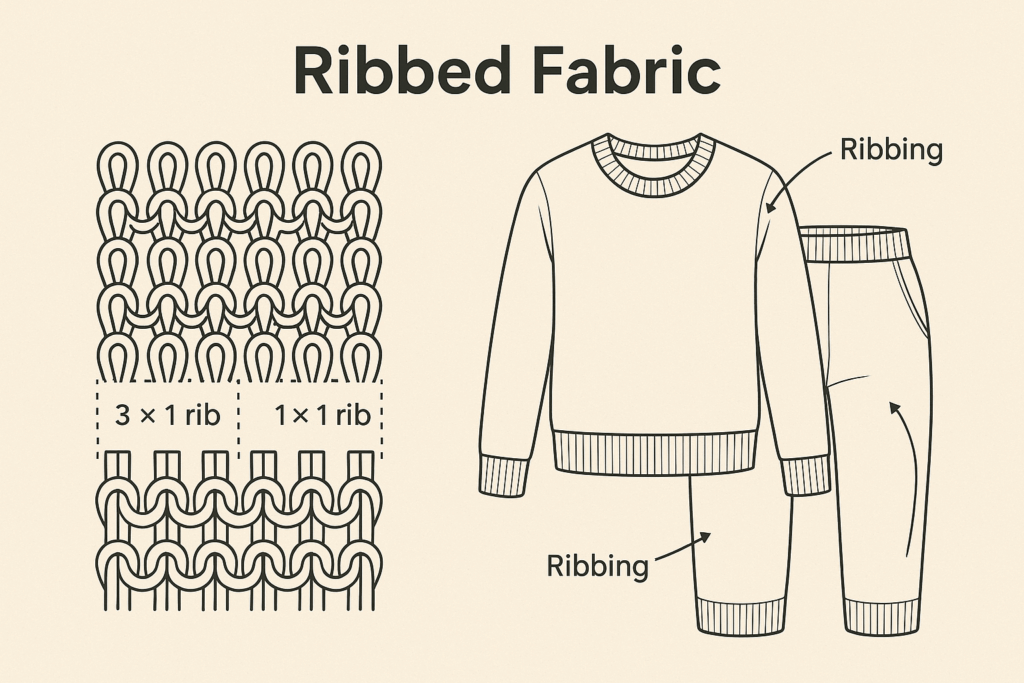

Ribbed fabric is a specialized type of knitted fabric known for its vertical ridges and exceptional stretch, especially in the horizontal direction. This fabric is created by alternating knit and purl stitches, forming rows of raised and recessed lines (ribs). Popular in both functional and decorative fashion applications, ribbed fabrics offer stretch, comfort, warmth, and style versatility.

How Ribbed Fabric is Made

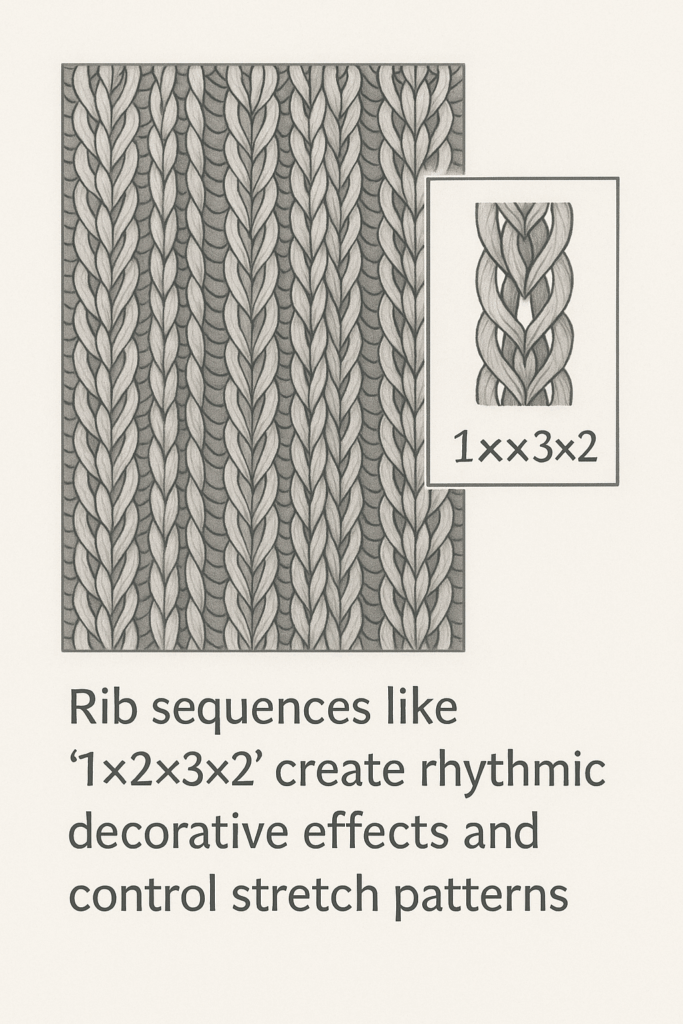

Ribbed knit fabric is produced using alternating front (knit) and back (purl) plain stitches. The result is a longitudinal rib structure that enhances both elasticity and shape retention. One of the most common configurations is the 1×1 rib knit, which is equivalent to “one front stitch, one back stitch” in hand knitting. Variations like 2×2 ribs, 3×1 ribs, or custom sequences (e.g., 1x2x1x2x3x2) allow designers to customize the appearance and stretch of the final product.

| Rib Type | Appearance | Common Use |

|---|---|---|

| 1×1 | Very elastic, fine ribs | Necklines, cuffs, hems |

| 2×2 | Moderate elasticity | Waistbands, collars |

| 3×1 | Decorative and supportive | Body-shaped garments, leggings |

Key Characteristics of Ribbed Fabric

- 🔄 Superior Elasticity: Offers more horizontal stretch than plain knit.

- ❄️ Thermal Insulation: Traps more air for warmth.

- 🧵 Structure Versatility: Can be used as base fabric or trim.

- ✂️ Shaping Ability: Molds naturally to the body shape.

- 🧶 Comfortable Texture: Often used in next-to-skin garments.

Applications in Garment Design

Ribbed fabric is used in a wide range of garments, particularly where fit and stretch are essential. Common applications include:

✅ Pajamas and Sleepwear

- Soft, breathable, and warm

- Allows full body movement while maintaining shape

✅ Children’s Clothing

- Flexible for growing bodies

- Durable and gentle on sensitive skin

✅ Thermal Underwear and Leggings

- Excellent for cold weather

- Rib structure traps heat and improves insulation

✅ Collars, Cuffs, and Hems

- Used as rib trims to improve fit and comfort

- Adds stretch and visual contrast to T-shirts, jackets, and sweaters

✅ Edge Processing (Piping & Welts)

- Ribbed knits make ideal bindings due to elasticity

- Used in fashion-forward or performance garments

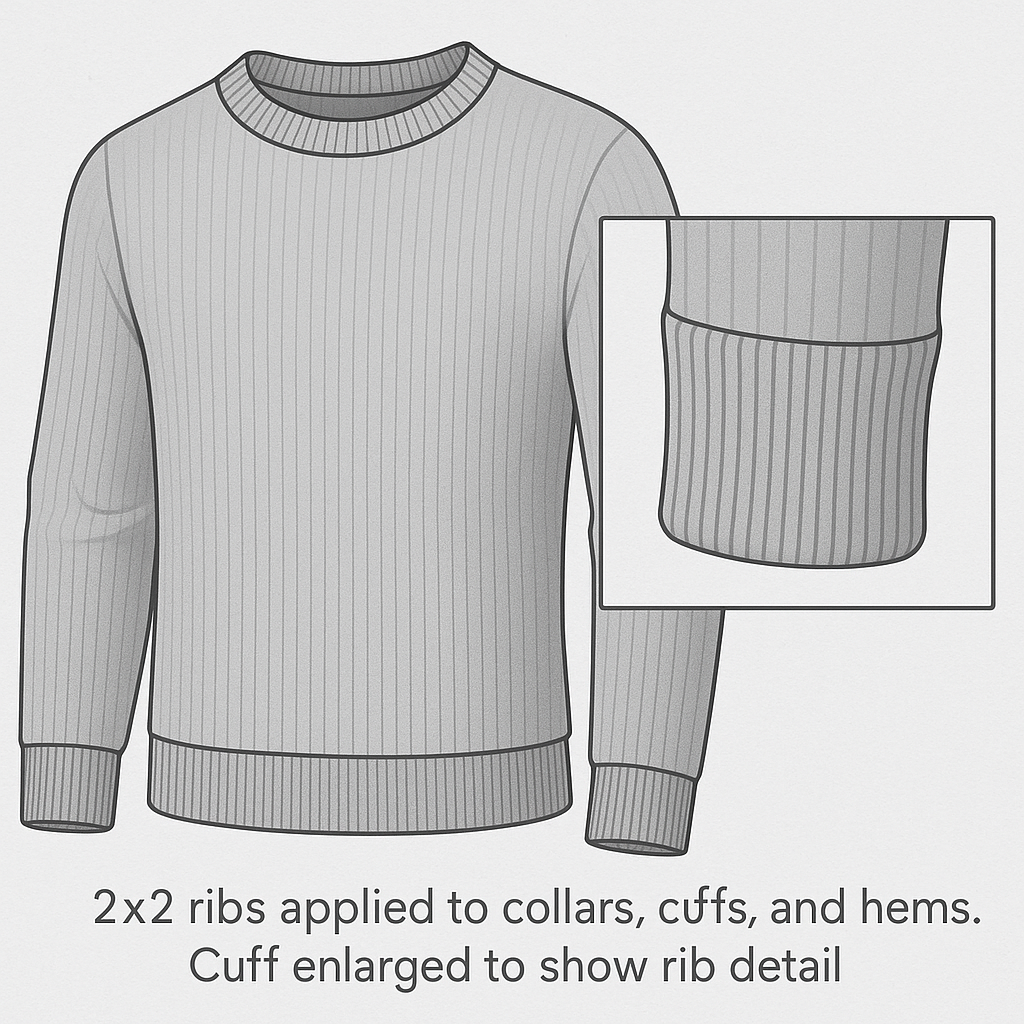

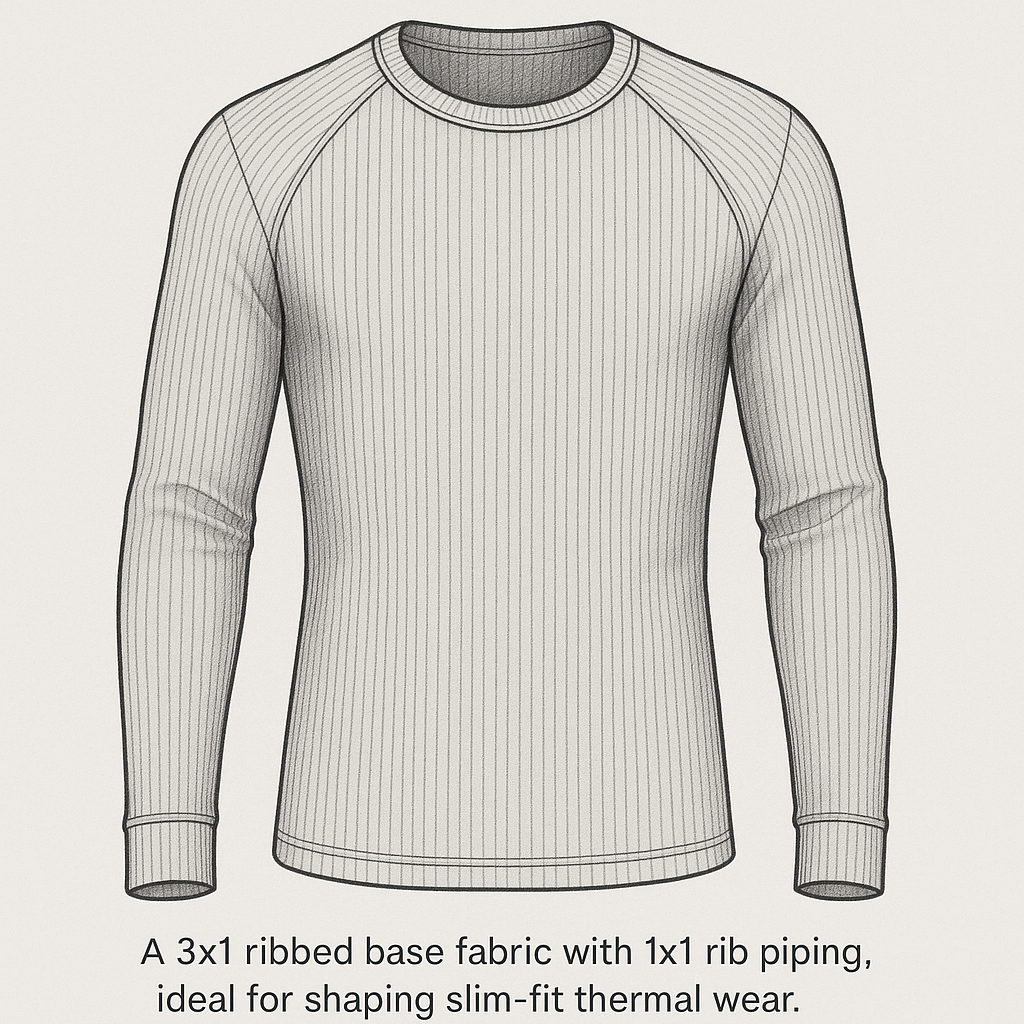

Technical Example: Figure Explained

- Figure a: A 3×1 ribbed base fabric with 1×1 rib piping, ideal for shaping slim-fit thermal wear.

- Figure b: 2×2 ribs applied to collars, cuffs, and hems. Cuffs are enlarged to show rib detail.

- Rib sequences like “1x2x3x2” create rhythmic decorative effects and control stretch patterns.

Ribbed Fabric vs. Jersey Fabric

| Feature | Ribbed Fabric | Jersey Knit |

|---|---|---|

| Stretch | More horizontal stretch | Less horizontal stretch |

| Insulation | Traps more air | Light and breathable |

| Fit | Closer to body | Looser fit |

| Common Use | Cuffs, thermals, trims | T-shirts, dresses |

| Cost per Yard | Slightly higher (more yarn) | Lower |

Production Efficiency & Cost

While ribbed fabric consumes more yarn than plain knit, it allows garments to be cut to smaller dimensions due to its stretch, potentially increasing production volume. For instance, a jersey T-shirt may use an 18-inch half-gauge, whereas a ribbed shirt could use 17 inches or less—an efficient approach in mass production.

Summary

Ribbed knit fabric combines comfort, elasticity, warmth, and aesthetic value, making it a go-to material for everything from base layers to stylish edge trims. Its ability to conform to the body without restriction enhances both wearability and garment performance. Whether used as a base fabric or finishing detail, ribbed fabric continues to be a staple in functional fashion and technical apparel.