🧷 Button Attachment Methods in Garment Manufacturing

Button attachment is not just a minor detail — it plays a critical role in garment quality, durability, and safety. Whether you’re producing fashionwear, workwear, or children’s clothing, how a button is sewn determines both the performance and perceived value of the final product.

This article explores machine and hand-sewn button attachment techniques, preferred stitches, and quality control tips — especially important for high-traffic or safety-critical garments.

🔹 Importance of Proper Button Sewing

- 🧵 Prevents detachment during use

- 👕 Extends garment lifespan

- ⚠️ Reduces risk of choking in children’s garments

- ✅ Improves customer satisfaction and brand trust

🔸 Common Stitch Types for Button Machines

1. Lock Stitch (Stitch Type 304)

✔️ Recommended for strong, durable attachment

✔️ Thread interlocks inside the fabric, minimizing fray

✔️ Great for medium to heavy fabrics

🔁 Creates secure, balanced tension on all button holes

2. Chain Stitch (Stitch Type 101)

⚠️ Not recommended for button sewing

❌ Can unravel from one loose thread

🧵 Often used for temporary attachments or low-load applications

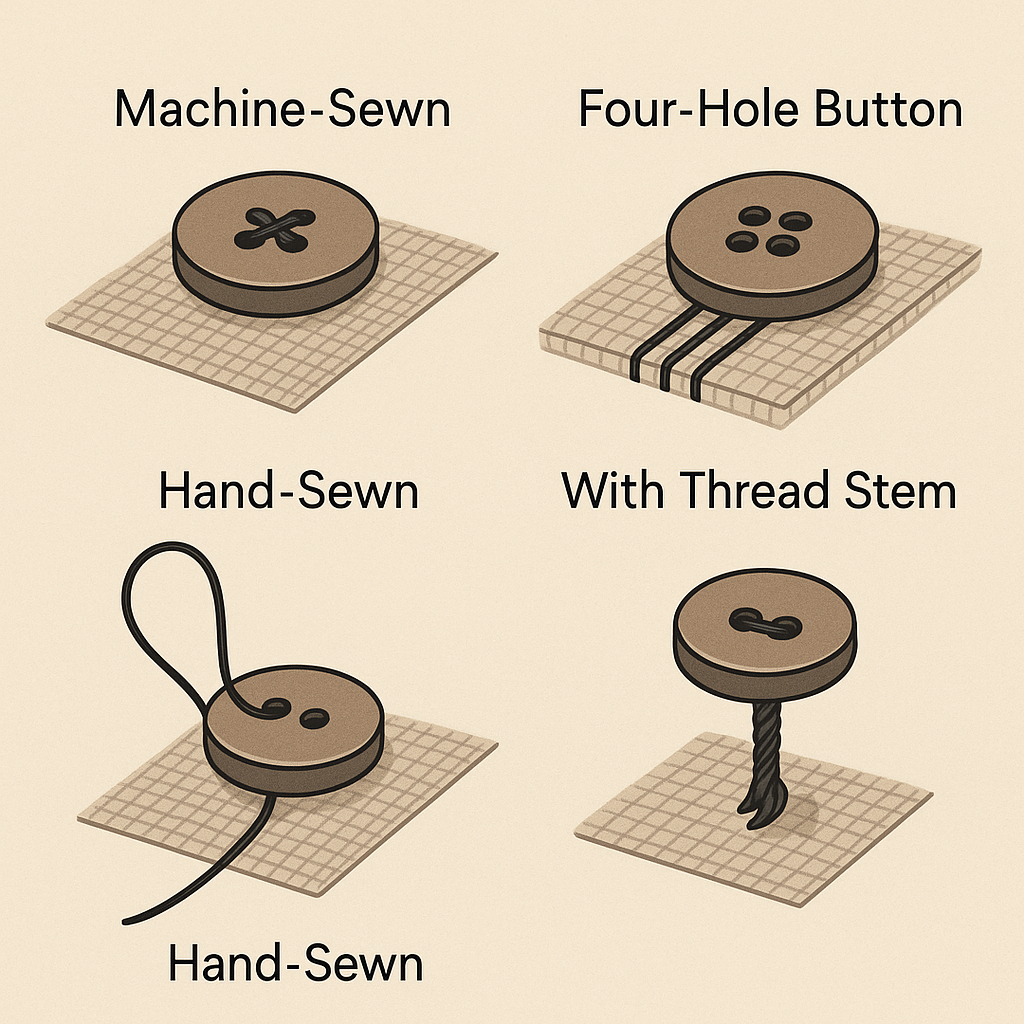

🧷 Button Hole Configurations and Sewing Techniques

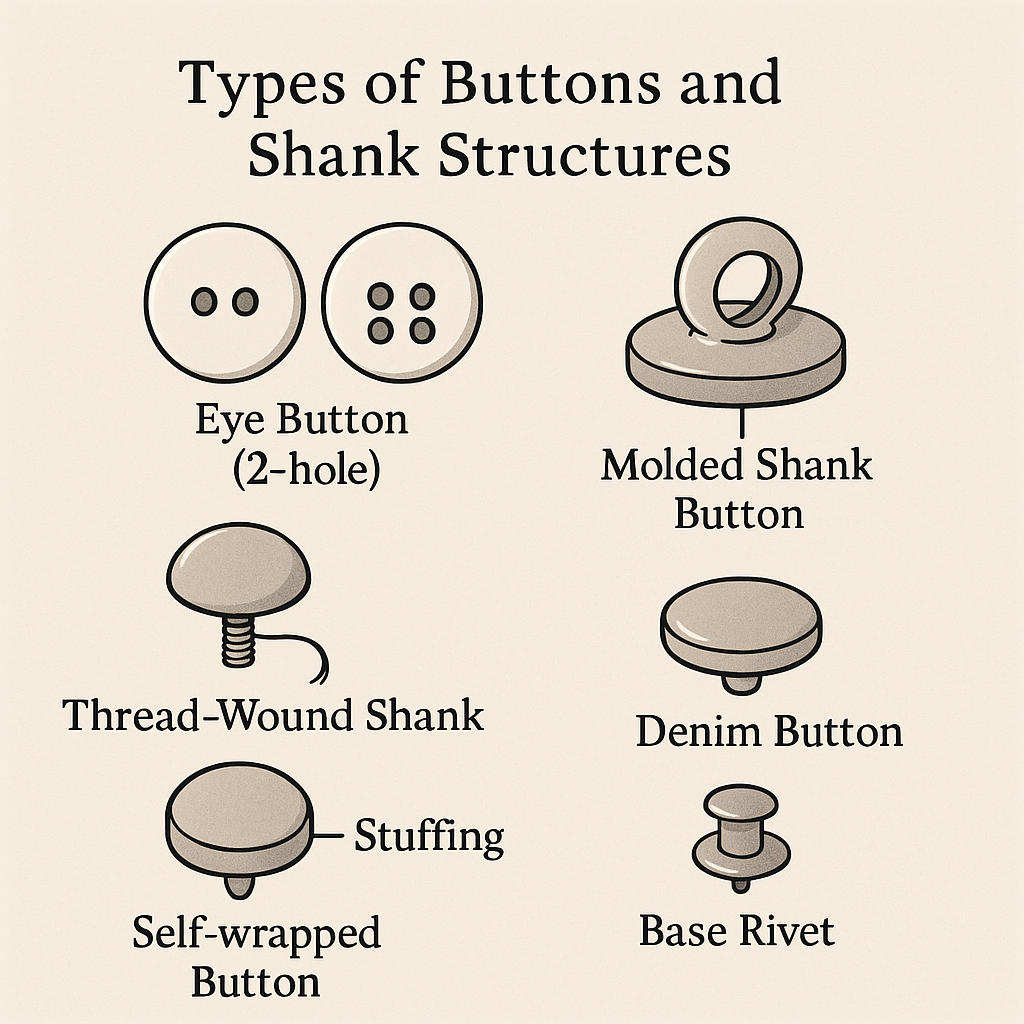

🟤 Two-Hole Buttons

- Can be sewn with or without a thread stem for spacing

- Suitable for lightweight fabrics

- Hand sewing allows better control over shank height

🟤 Four-Hole Buttons

- X-shape stitch: Classic, with double thread

- Parallel stitch: Creates a square or box shape

- Four-thread method: Highly secure and more durable than 2-hole versions

- Recommended for outerwear, uniforms, or children’s clothing

📌 Tip: Stitch each pair of holes separately for extra strength.

🪡 Hand Sewing Buttons: When & Why

While machine-sewn buttons are common, some garments still require hand-sewn buttons, particularly:

- French plackets with hidden buttons

- Heavy fabrics (e.g., wool coats, denim)

- Designer or bespoke garments

Creating a Hand-Wound Thread Stem:

- Pass the needle multiple times through the button and fabric.

- Insert a pin or toothpick under the button to create space.

- Remove the pin and wrap the thread tightly around the stem to secure it.

- Knot the thread under the wrap for reinforcement.

✔️ This thread stem acts as a shank, giving the button room to rest naturally above thicker fabrics.

🚸 Safety Note: Button Strength in Children’s Clothing

- Buttons must pass tensile strength tests

- Weak button attachment = choking hazard

- Reinforce all buttons with secure stitching and shank wrapping

- Use lock stitch (304) and inspect every button

📌 Best Practice: Perform pull testing on children’s garments as part of quality control.

✅ Summary of Best Practices

| Button Type | Preferred Stitch | Method | Application |

|---|---|---|---|

| 2-Hole (light fabric) | Lock stitch 304 | Machine/Hand | Shirts, blouses |

| 4-Hole (medium fabric) | Lock stitch 304 | Machine | Jackets, school uniforms |

| Decorative/Hidden | Hand sewing | With thread stem | French plackets, designer pieces |

| Children’s Buttons | Lock stitch 304 | Machine | Must pass strength testing |