Key Elements Included in the Fitting Records and Sample Evaluation Section

Fitting Session Documentation

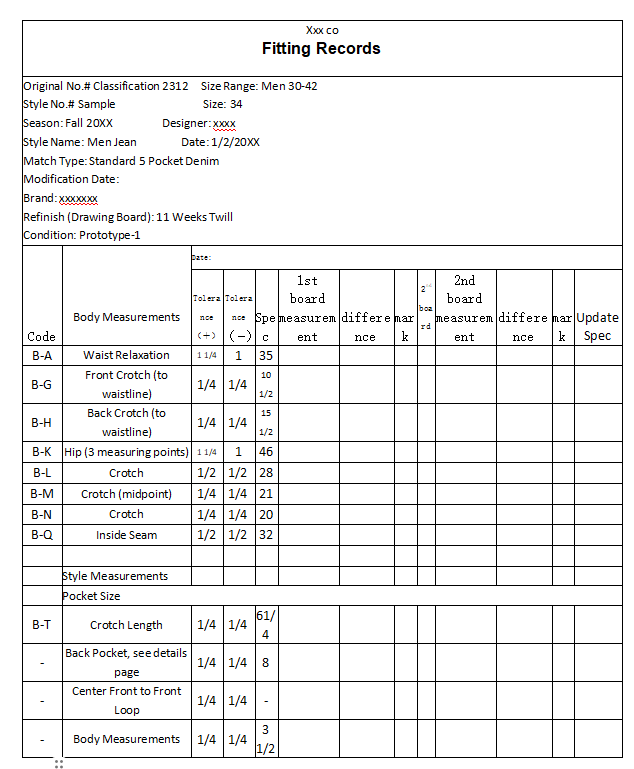

- Fitting sessions are crucial for assessing the garment’s fit on a real body, not just in theory. These sessions typically involve a sample of the garment being tried on by a model or fit model who represents the target customer. The Fitting Records section provides a detailed log of each fitting session, including the fit model’s measurements and any observed issues or changes that need to be made.

Key information typically recorded during fitting sessions includes:

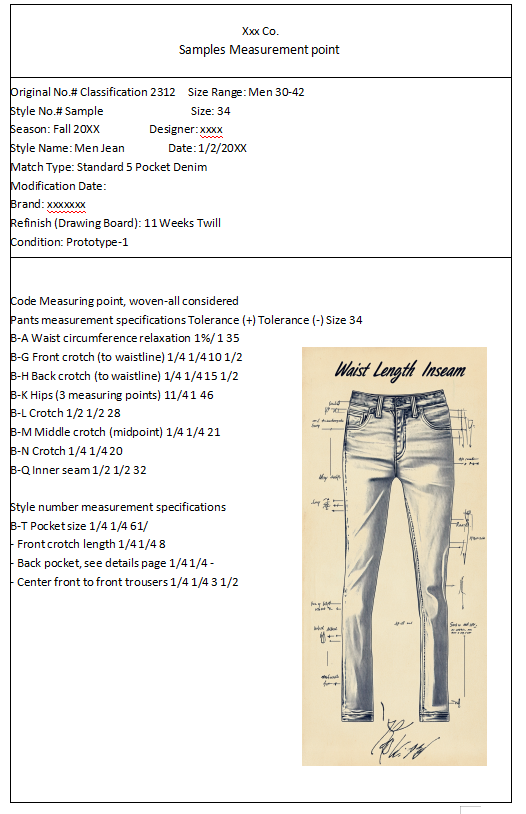

- Fit Model Details: This includes the fit model’s body measurements, size, and any specific characteristics that are relevant to the garment’s fit. This information helps assess how well the garment fits a representative person.

- Fit Observations: The technical team and designer make observations about the garment during the fitting session. This includes how the garment fits around the bust, waist, hips, shoulders, arms, and length.

- Loose Areas: Any areas where the garment is too loose or lacks structure (e.g., loose shoulders, baggy waist, etc.).

- Tight Areas: Any parts that feel tight or uncomfortable (e.g., tight armholes, constricting waistbands).

- Fabric Behavior: How the fabric responds to movement, stretch, or body shape. Certain fabrics may stretch out or wrinkle excessively, which could require adjustments.

- Overall Fit: General comments on how the garment fits overall and if it aligns with the desired silhouette (e.g., slim fit, relaxed fit, tailored fit).

Example Fit Observation:

- Bust: Garment fits well around the bust, but the armholes feel too tight. Recommend adjusting armhole size by 0.5 inches.

- Waist: Waistband fits snugly, but the garment would benefit from 1 inch more ease at the waist to allow for more comfort.

These observations help create a clear, actionable plan for making the necessary adjustments to the sample.

Sample Evaluation Notes

- After the fitting session, the Sample Evaluation provides an in-depth assessment of the garment based on the designer’s standards, functionality, and aesthetic qualities. The evaluation focuses on various aspects, including the construction, stitching, fabric, design features, and overall appearance.

Key evaluation criteria may include:

- Construction Quality: The sample is assessed for construction quality, including the accuracy of stitching, seam finishes, and overall durability. Any areas with poor stitching or unfinished seams should be noted.

- Fabric Choice: The fabric’s performance is evaluated. For example, does it have the right drape? Does it stretch, shrink, or wrinkle excessively? Does it match the designer’s vision?

- Design Accuracy: The sample is checked to ensure it matches the design specifications in the process sheet, such as design lines, trims, embellishments, and overall silhouette.

- Fit Evaluation: This part of the evaluation looks at how well the garment fits, especially in critical areas like the bust, waist, hip, sleeve, and inseam. The evaluator checks that the fit aligns with the intended design.

- Comfort and Wearability: Is the garment comfortable to wear? Are there any areas that could cause discomfort, such as tight armholes, stiff collars, or irritating seams? Wearability is particularly important for garments that will be worn for long periods.

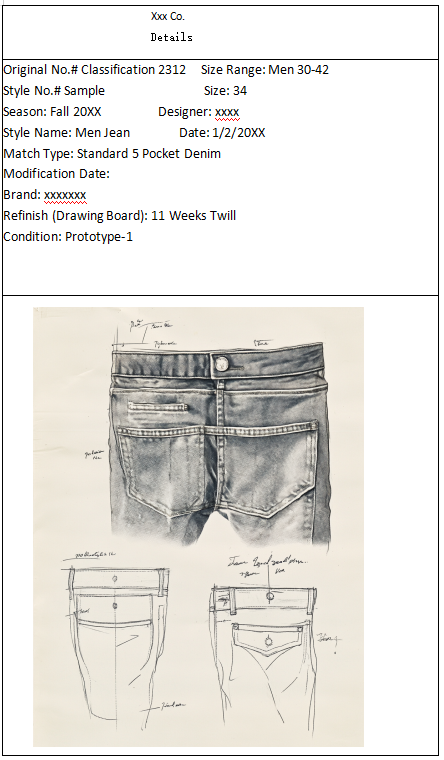

- Functionality: This is particularly important for garments with functional elements like pockets, zippers, or buttons. The ease of use, placement, and durability of these features are evaluated.

- Aesthetic Appeal: The garment is assessed for overall aesthetic appeal. Does it look as expected? Are there any visual discrepancies? Does it achieve the intended look and feel (e.g., casual, formal, athletic)?

Example Sample Evaluation:

- Stitching Quality: The stitching is even and consistent, but the side seams need reinforcement as they may fray over time. Recommend using a French seam for added durability.

- Fabric Performance: The fabric looks good, but it wrinkles easily after sitting. Suggest switching to a blend with wrinkle-resistant properties.

- Fit: The fit is good around the bust and waist, but the sleeves feel too tight. Increase sleeve width by 0.75 inches and add 1 inch of ease in the upper arm.

These evaluations help the design team make the final adjustments needed to refine the garment before it moves into full-scale production.

Modification and Adjustment Instructions

- Following the fitting and sample evaluation, the process sheet will include specific instructions for any required modifications or adjustments. This ensures that the garment’s design and fit meet both the designer’s standards and the manufacturer’s production capabilities.

Common modification instructions may include:

- Adjusting Seam Allowances: If a garment needs more room in certain areas, such as the bust or waist, the pattern may need to be adjusted by altering the seam allowances.

- Revising Measurements: If the fit model’s feedback indicates that the garment is too tight or too loose in certain areas, measurements may be adjusted accordingly.

- Changing Construction Techniques: The construction technique may need to be altered based on feedback. For example, if a certain seam is not durable enough, it may be replaced with a more robust stitching method.

- Fabric Change: Based on the sample evaluation, the fabric may be swapped for one that better aligns with the intended design, durability, or comfort level.

Example Modification Instruction:

- Bust: Increase bust circumference by 1 inch and add 0.5 inch of ease across the chest.

- Sleeves: Widen the sleeves at the armhole by 0.75 inches for more comfort and mobility.

- Fabric: Change from 100% cotton to a cotton-polyester blend for a more wrinkle-resistant finish.

These adjustments are critical to perfecting the fit and overall design before production begins.

Approval and Sign-off

- Once all the adjustments have been made and the sample is re-evaluated, the garment is ready for final approval. The Approval and Sign-off process ensures that the designer, technical team, and manufacturer are all aligned on the final product.

Key components of this process:

- Designer Approval: The designer reviews the final sample and approves it for production. This is the final check to ensure that the garment meets the original design vision.

- Manufacturer Approval: The manufacturer also signs off on the sample to confirm that it meets production standards and is feasible for large-scale manufacturing.

- Fit Model Approval: If applicable, the fit model may be asked to review the final sample to confirm that the adjustments provide a better fit.