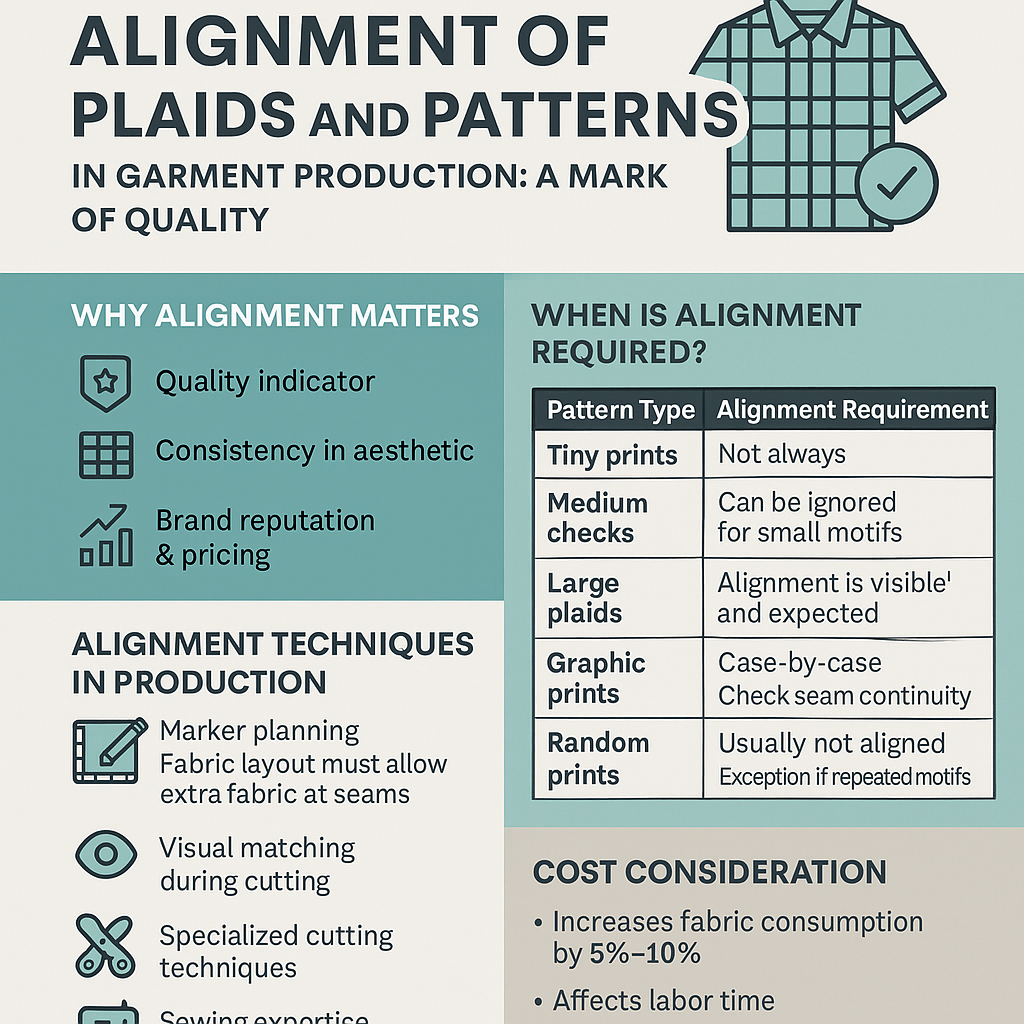

🧵 Alignment of Plaids and Patterns in Garment Production: A Mark of Quality

What Is Pattern Alignment?

Pattern alignment refers to the careful matching of printed designs, plaids, or graphics at seam lines and across garment panels. It’s a meticulous process that ensures aesthetic harmony in finished garments, especially in high-end fashion or tailored clothing.

🟢 Why Alignment Matters

- Quality Indicator

Seam alignment, especially in plaids and printed patterns, is one of the most visible signs of garment craftsmanship. Misaligned seams can make a garment look cheap, even if high-quality fabric is used. - Consistency in Aesthetic

Pattern alignment enhances visual symmetry, which is essential in checks, stripes, florals, and geometric prints. - Brand Reputation & Pricing

High-end brands are expected to maintain alignment. A well-aligned garment demands more fabric and labor, justifying a higher price.

🎯 When Is Alignment Required?

| Pattern Type | Alignment Requirement | Remarks |

|---|---|---|

| Tiny Prints | Not Always | Can be ignored for small motifs |

| Medium Checks | Yes | Alignment is visible and expected |

| Large Plaids | Absolutely Required | Misalignment is obvious |

| Graphic Prints | Case-by-case | Check seam continuity |

| Random Prints | Usually not aligned | Exception if repeated motifs |

🧩 Alignment Techniques in Production

- Marker Planning

Fabric layout must allow extra fabric for alignment at seams. This increases fabric consumption by approximately 5%–10%. - Visual Matching

During cutting, operators align pattern points with notches or gridlines to ensure the final pieces can be sewn seamlessly. - Specialized Cutting

Use of CAD systems (like Gerber AccuMark) helps generate smart markers that account for repeat lengths and fabric shrinkage. - Sewing Expertise

Sewing personnel must be trained to join edges with pattern repeat accuracy — particularly for chest, side seams, and center fronts.

✂️ Cost Consideration

Pattern alignment significantly affects:

- Fabric yield (more waste due to match requirements)

- Labor time (requires precision in cutting and sewing)

- Sampling (additional trial runs for alignment testing)

Pro tip: Always calculate alignment needs in the first tech pack or process order to avoid last-minute surprises.

🔍 Quality Inspection Checklist

✅ Plaid lines match at side seams

✅ Graphics align at center fronts

✅ Collar and pocket placement are symmetrical

✅ Hem alignment is clean and continuous

✅ Repeat patterns flow consistently across panels

📌 Conclusion

Aligning plaids and patterns isn’t just a design choice—it’s a production discipline. Whether you manufacture women’s skirts, men’s shirts, or tailored coats, pattern alignment enhances garment quality, brand image, and customer satisfaction.