Bottom Seam in Knitted Garments: Structure, Stitching, and Applications

🧵 What is a Bottom Seam?

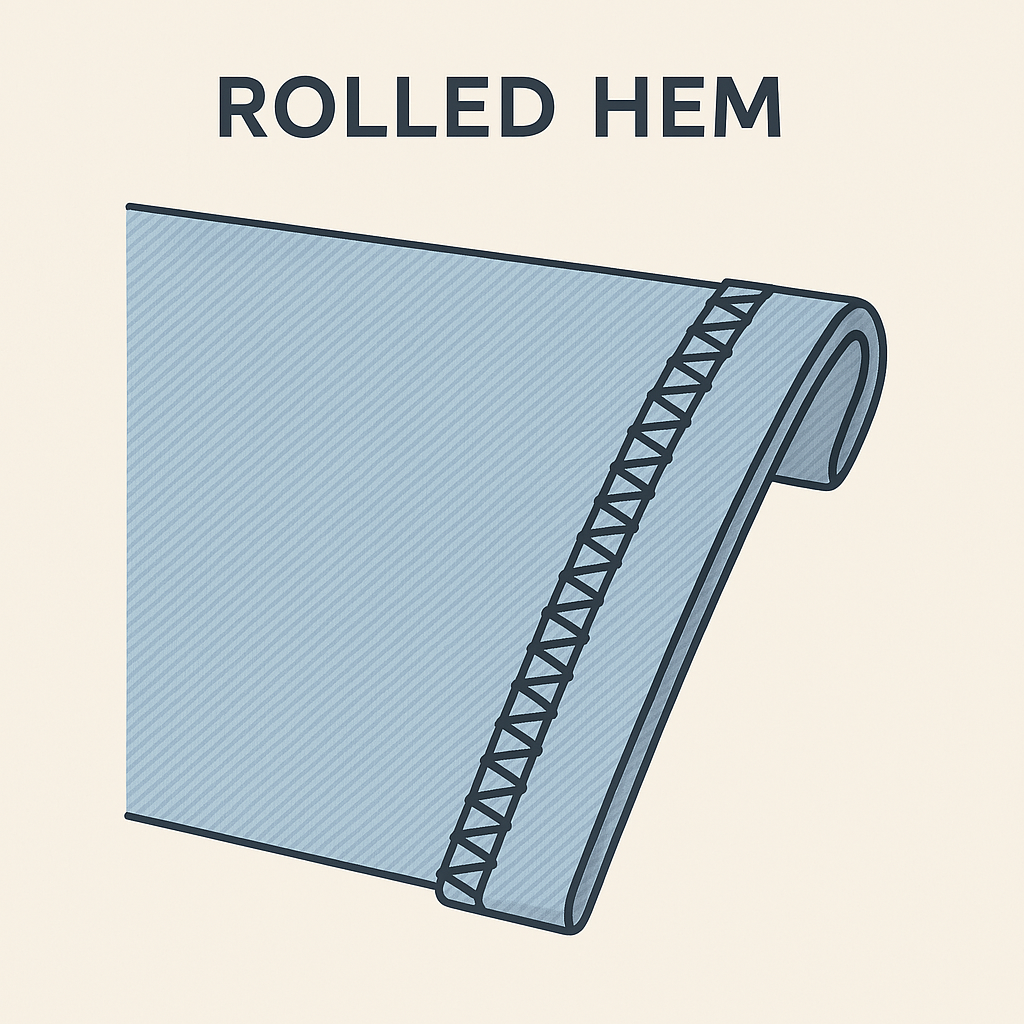

A bottom seam is a common hem treatment in knitwear construction, especially used in T-shirts, knit skirts, and other lightweight stretch garments. Unlike traditional hemming methods that may cause fabric bulk or stiffness, the bottom seam offers flexibility and preserves the fabric’s original elasticity.

This seam style involves two layers of knit fabric stitched together—making it slightly less raised or “fluffy” than a typical hem seam. It’s known for its clean appearance, stretch compatibility, and efficient construction using coverstitch machines.

🔍 How Bottom Seams Are Constructed

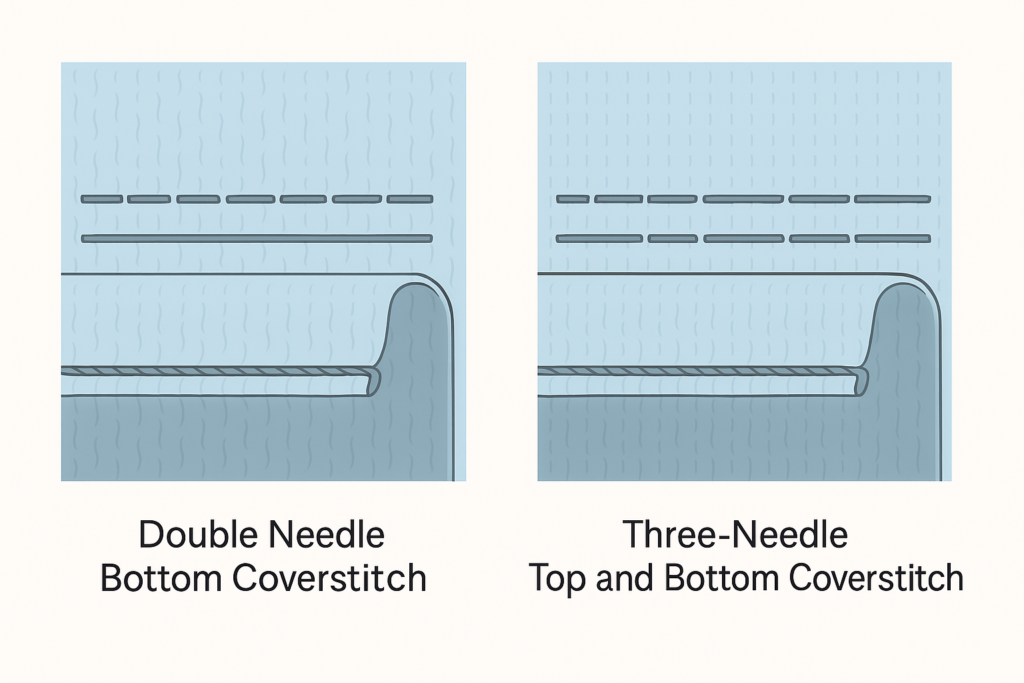

🔹 Double-Needle Bottom Coverstitch

- Visible Side (Front): Displays two parallel lines of stitching.

- Underside (Back): Features a serpentine or spiral stitch.

- Function: Secure enough to act as both a seam and a finished raw edge.

- Benefit: Maintains stretch and shape of the garment without puckering.

📌 Commonly used for: T-shirt hems, knitwear sleeves, casual dresses.

🔹 Three-Needle Top & Bottom Coverstitch

- Structure: Includes three needles on top with interlocking loops underneath.

- Advantage: Provides extra durability and flexibility in high-stress areas.

- Application: Often used on activewear or thicker knits for added strength.

⚙️ Recommended Machines

Bottom seam construction is best executed on coverstitch machines equipped with a differential feed system. This allows multiple layers of knit fabric to feed through at different speeds, helping prevent:

- Stretch distortion

- Fabric puckering

- Uneven seams

💡 Common Models Used:

- Model 600: Excellent for double-needle bottom seam operations

- Model 406: Suitable for both light and medium weight knits

👗 Garment Use Table for Bottom Seam

| Garment Type | Seam Type | Machine Model | Fabric Type | Purpose / Notes |

|---|---|---|---|---|

| T-shirts | Double-Needle Bottom Seam | 600 | Cotton, Jersey | Clean hem finish, retains stretch |

| Knit Skirts | Double or Triple Needle Seam | 406 | Rib Knit, Interlock | Flat finish at the hemline |

| Sweatshirts | Three-Needle Coverstitch | 406 | French Terry, Fleece | Durable for heavier knit hems |

| Sportswear Tops | Double-Needle Bottom Seam | 600/406 | Lycra, Polyester | Flat, stretchable seam that won’t deform |

| Casual Dresses | Double-Needle Coverstitch | 600 | Rayon Spandex | Maintains shape and elasticity at bottom hemline |

🌟 Key Advantages of Bottom Seams

✅ Perfect for stretch fabrics

✅ Clean, professional finish

✅ Eliminates the need for separate raw edge finishing

✅ Compatible with industrial machines for mass production

✅ Prevents fabric deformation during stitching

🔧 Tips for Perfect Bottom Seam Stitching

- Use differential feed settings correctly to avoid stretching.

- Match thread type with fabric for optimal flexibility.

- Always test-stitch on fabric scraps before production.

- Maintain proper needle spacing for even, professional results.

- Use ballpoint needles to prevent knit snags.

📌 Summary

The bottom seam is an essential construction method in the world of knit garments, offering a smooth, stretch-compatible finish. With the right machine (Model 600 or 406) and proper differential feed settings, manufacturers can achieve high-quality seams that not only look professional but also enhance garment comfort and longevity.