🌟 Directional Fabrics: A Guide for Designers and Pattern Makers

✂️ What Are Directional Fabrics?

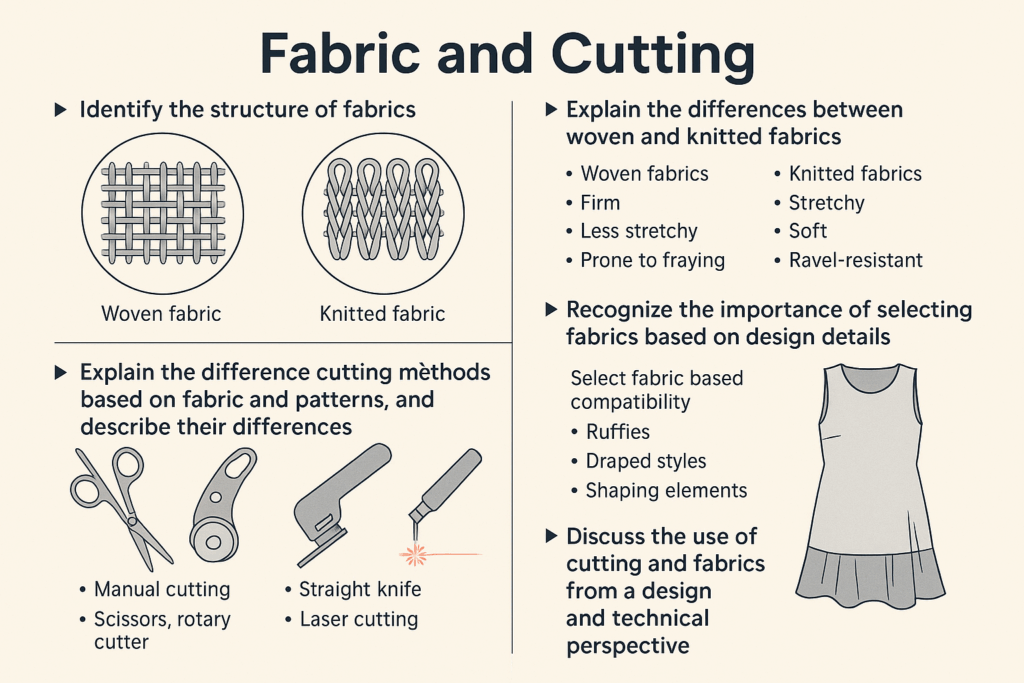

Directional fabrics refer to textiles that exhibit a distinct direction due to elements like prints, naps, textures, or sheen. Cutting such fabrics incorrectly can disrupt the garment’s appearance and reduce its quality. Understanding fabric direction is essential for cost control, alignment, and achieving a professional finish.

📐 Common Types of Directional Fabrics

1. Bias Weaves

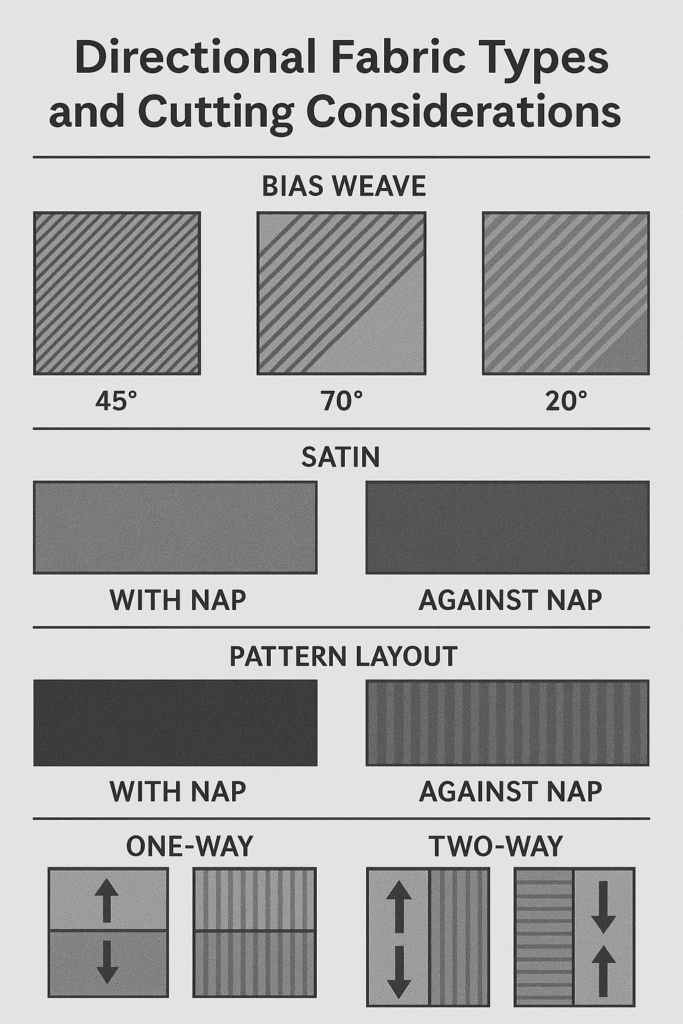

Bias weaves such as twill, denim, gabardine, and herringbone tweed have a diagonal rib or grain that runs across the fabric, typically at 45°, but can vary (e.g., 20° slow twill or 70° sharp twill). These angles affect:

- Color perception: Colors may appear darker or lighter depending on the angle.

- Drape and stretch: Bias weaves stretch diagonally, impacting garment fit.

- Cutting layout: Garments should be cut in one consistent direction for visual harmony.

🔍 Pro Tip: Always inspect a full yard of the fabric—not just a swatch—to judge the directionality and color shifts.

2. Fabrics with Shiny Surfaces

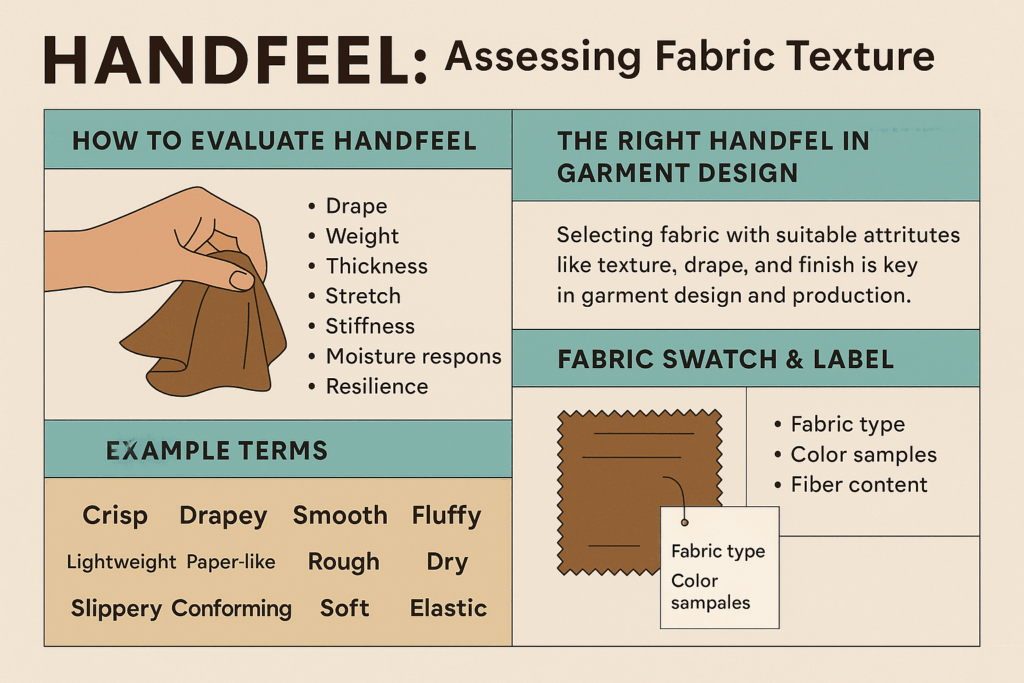

Fabrics like satin, taffeta, calendered cotton, and silk have reflective surfaces that create shadows and highlights depending on lighting and angle.

🌈 These fabrics can:

- Look darker or lighter based on how light hits them.

- Cause inconsistent appearance in garments if cut without directionality.

- Require one-way cutting to maintain uniform sheen.

🧪 Best Practice: Test with both one-way and two-way layouts. Factories may prepare sample garments for buyer evaluation before full production.

3. Napped and Pile Fabrics

Fabrics like velvet, corduroy, and faux fur have a visible nap. When stroked in one direction, the fibers lie flat, appearing shiny; when reversed, they appear darker or matte. Always cut nap fabrics in the same direction to avoid visual mismatch.

🎨 Directional Elements in Printed & Striped Fabrics

Uneven plaids, border prints, and asymmetrical stripes should also be treated as directional. Not aligning these elements during layout may result in unbalanced or distracting visuals.

🧵 How Directionality Affects Garment Design and Cost

| Directional Fabric Type | Cutting Requirement | Cost Impact | Risk if Ignored |

|---|---|---|---|

| Twill / Herringbone | One-way | ↑ Fabric waste (15%) | Uneven drape, color mismatch |

| Satin / Taffeta | One-way preferred | Moderate | Shiny inconsistency |

| Velvet / Corduroy | One-way required | High | Patchy surface tone |

| Uneven Plaids | One-way or symmetrical | High | Visual misalignment |

🛠️ Tips for Working with Directional Fabrics

- 📏 Mark grainline clearly on every pattern piece.

- 🧶 Test layout with mock fabric or muslin before cutting actual material.

- 🧷 Use consistent cutting direction to maintain surface appearance.

- 💰 Include additional fabric waste in cost estimates (especially for one-way cutting).

✅ Conclusion

Directional fabrics bring richness and complexity to garments—but they demand careful planning. Whether you’re working with twill, satin, or velvet, aligning the direction of each piece ensures the final design is cohesive, elegant, and high-quality. Taking the time to test layouts and understand fabric behavior ultimately leads to better results and happier clients.