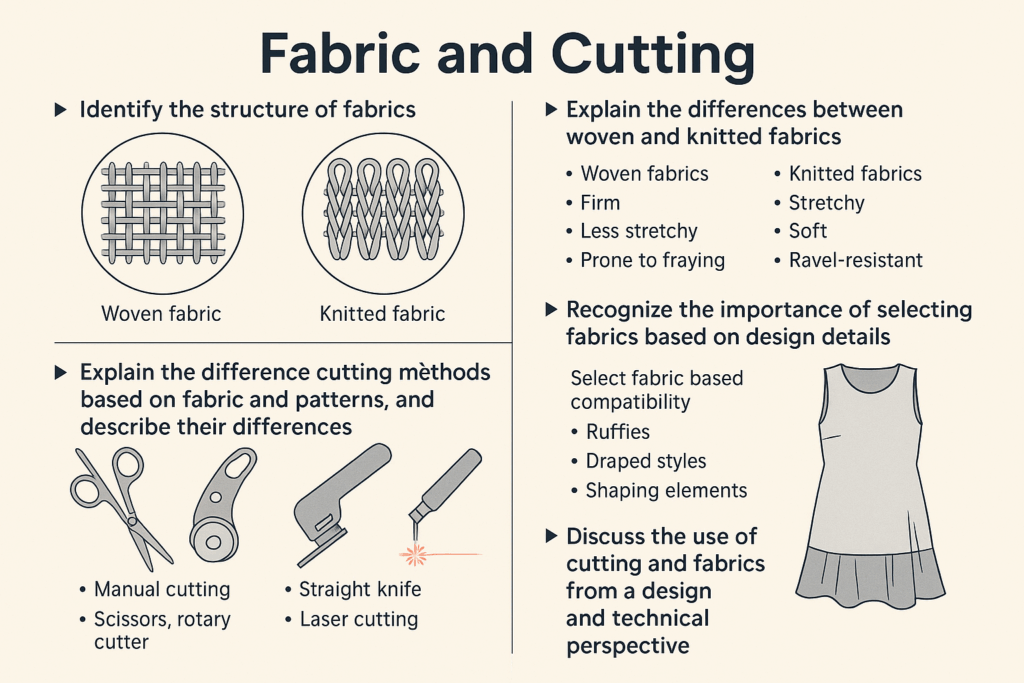

Fabric and Cutting: Structure, Methods & Design Considerations

🧵 Understanding Fabric Structure

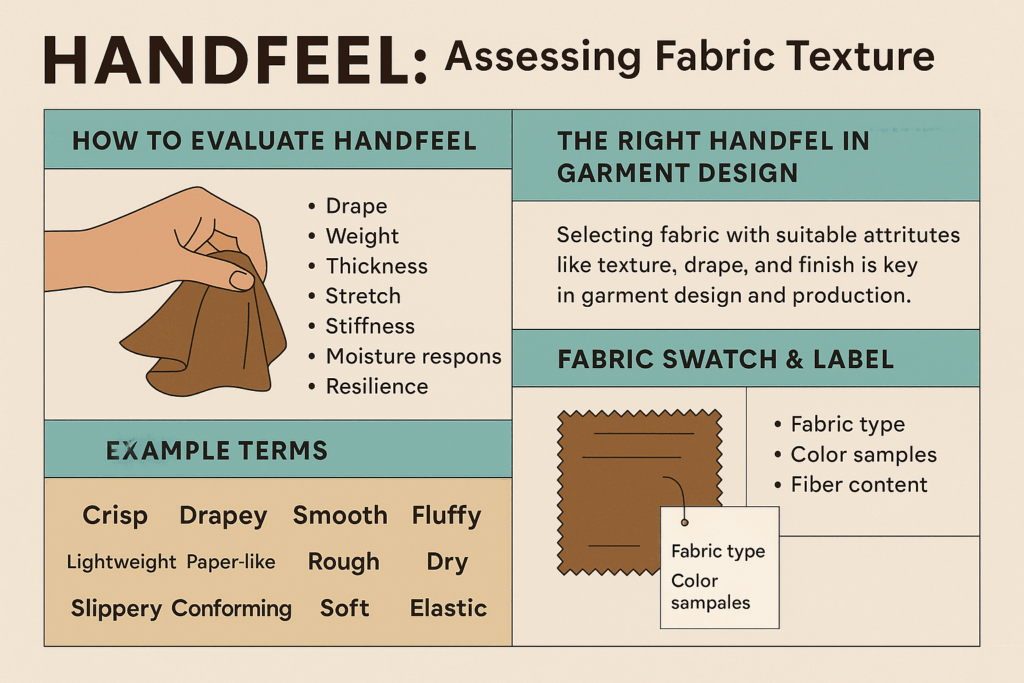

Fabric structure is the foundation of garment performance and appearance. It influences drape, stretch, durability, comfort, and how a fabric responds during cutting and sewing.

🔸 Types of Fabric Structures

- Woven Fabrics

- Created by interlacing warp (vertical) and weft (horizontal) yarns

- Firm, stable, and ideal for structured garments

- Examples: Cotton poplin, denim, twill, organza

- Knitted Fabrics

- Constructed by interlooping yarns

- Stretchy, soft, and ideal for casualwear, activewear, and lingerie

- Examples: Jersey, rib knit, interlock, pique

📌 Understanding the structure helps predict how a fabric behaves during cutting, seaming, and wearing.

✂️ Woven vs. Knitted Fabrics: Key Differences

| Feature | Woven Fabrics | Knitted Fabrics |

|---|---|---|

| Construction | Interlaced yarns | Interlooped yarns |

| Stretch | Low (unless elastane added) | Naturally stretchy |

| Drape | Crisp or structured | Fluid and soft |

| Fray Risk | High – requires seam finishes | Low – edges curl instead |

| Cut Direction | Critical (grainlines matter) | More flexible with orientation |

| Application | Shirts, pants, jackets | T-shirts, leggings, sportswear |

🎯 Cutting and finishing methods depend heavily on whether fabric is woven or knit.

✂️ Cutting Methods Based on Fabric and Patterns

🔸 Manual Cutting

- Ideal for small production or sample rooms

- Uses scissors or rotary cutters

- Suitable for delicate fabrics or one-off designs

🔸 Die Cutting

- Uses metal templates (dies) to stamp out shapes

- Precise and fast for repeat shapes, like accessories or trims

- Best for non-stretch woven materials

🔸 Straight Knife & Band Knife Cutting

- Automated or semi-automated; used in mass production

- Multiple layers of fabric stacked and cut together

- Great for bulk woven and knit fabrics

- Requires careful alignment of grain and pattern

🔸 Laser Cutting

- Used for synthetics or complex designs

- Clean edges—especially effective for fabrics like polyester or nylon

- Not ideal for natural fibers (may scorch)

🧷 Importance of Fabric Choice for Design Details

Choosing the correct fabric is critical to achieving the desired silhouette, texture, and functionality of a garment.

| Design Detail | Recommended Fabric Type | Reason |

|---|---|---|

| Sharp pleats | Crisp woven (e.g., taffeta) | Holds pleat definition |

| Drape & flow | Lightweight knit or rayon | Enhances movement |

| Structured tailoring | Twill, suiting wool | Provides shape and durability |

| Soft gathers | Jersey, chiffon, crepe | Allows fluid gathering without stiffness |

| Heat-formed shapes | Synthetic blend (e.g., polyester) | Holds sculpted form with pressing |

📌 Design elements such as darts, gathers, ruffles, and bias cuts rely on fabric behavior to maintain their intended appearance.

🪡 Design Meets Technique: The Role of Fabric and Cutting

From a design and technical perspective, the synergy between fabric selection and cutting precision affects:

- Garment fit – incorrect grain or fabric mismatch can distort the final silhouette

- Sewing quality – stretchy or slippery fabrics require special handling and needle types

- Production efficiency – knowing how a fabric responds to cutting can reduce waste and streamline sewing

✨ Designers must collaborate with pattern makers and cutters to align aesthetic vision with technical feasibility.

📌 Summary

Understanding fabric structure and cutting methods is essential for both creative garment design and technical production accuracy. Woven and knitted fabrics offer different advantages, and choosing the right cutting method depends on fabric behavior and production scale. A well-designed garment begins with the right fabric and a precise cut—balancing beauty, function, and manufacturability.