Learn about the role of a process sheet in garment production, the essential components it includes, and how it ensures smooth communication between designers and manufacturers in the fashion industry.

In the garment production process, clear communication between designers and manufacturers is crucial. One of the most important documents that facilitate this communication is the process sheet (also known as a technical specification package or tech pack). While the name may vary between companies, the purpose remains the same: to provide detailed guidance for manufacturing the garment from concept to final production.

In this article, we’ll dive into the function, content, and structure of a process sheet, explaining how it helps streamline the product development cycle and ensures that garments meet design specifications, quality standards, and deadlines.

What is a Process Sheet in Garment Production?

The process sheet is a comprehensive document that outlines all the necessary details for manufacturing a garment. This document serves as the main communication tool between the brand’s designers and the manufacturing team, helping them understand every aspect of the product’s creation. Whether you’re a designer, a manufacturer, or someone in the garment production industry, the process sheet ensures that everyone is aligned, from initial design to the final product.

Key Functions of the Process Sheet

The process sheet plays several vital roles in the garment production process:

Clear Production Method:

The process sheet specifies the exact production methods and steps required to create the garment. This includes the fabrics, materials, and accessories used, ensuring the final product aligns with the design vision.Color Matching and Specifications:

It details the color scheme for each style, ensuring that manufacturers use the correct shades of fabric, dye, and trim.Fit Specifications and Grading Principles:

This section covers sizing and fit instructions, including how the garment should be graded for different sizes.Labeling, Tags, and Ancillary Information:

The process sheet provides guidance on where to place labels and tags, along with any other relevant information required for packaging and branding.Packaging Information:

Details about how the finished garment should be packaged for distribution are also included, from folding instructions to how each item is labeled and boxed for shipment.

Essential Components of a Process Sheet

While each company may have its own format for a process sheet, the general structure includes the following key sections:

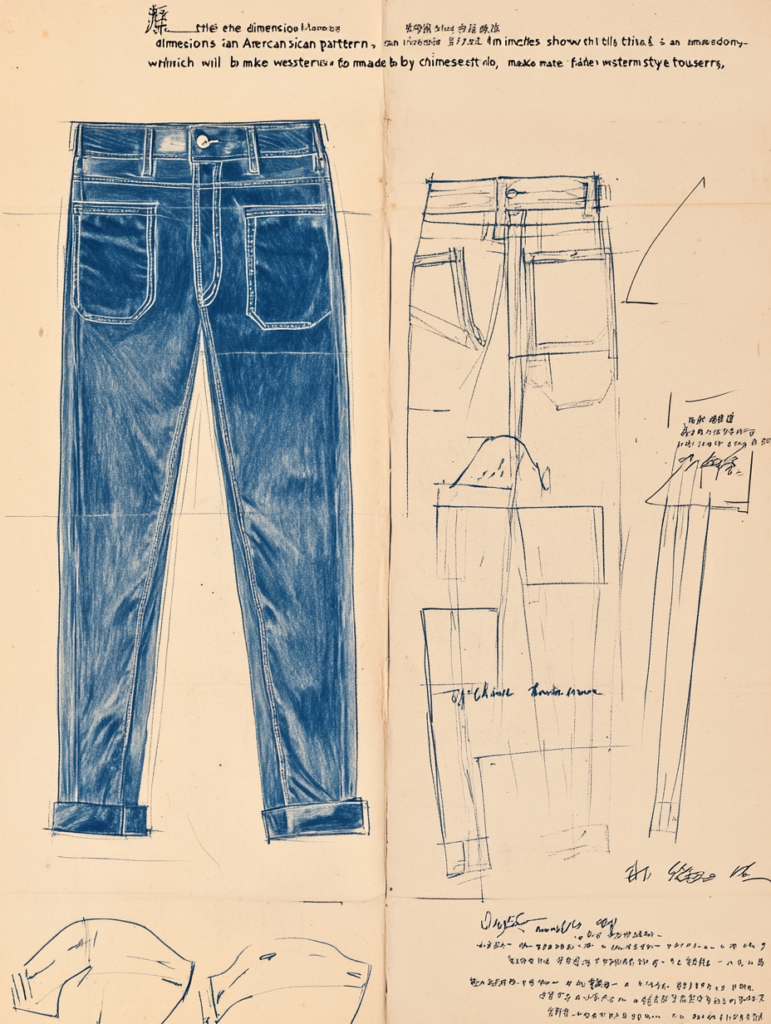

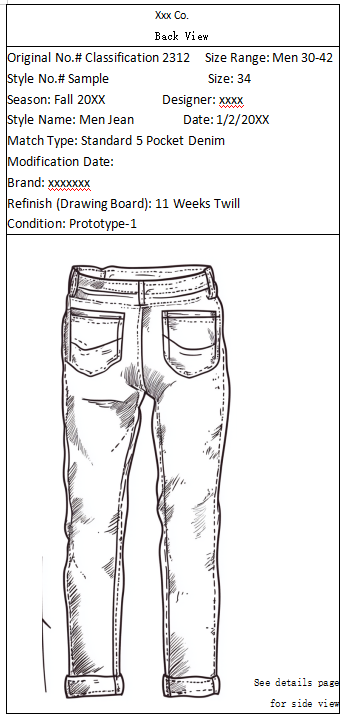

1. Front and Back Views

- The process sheet typically includes clear visual representations of the garment, showing both the front and back views of the design. These sketches help manufacturers visualize the garment’s structure and key design elements.

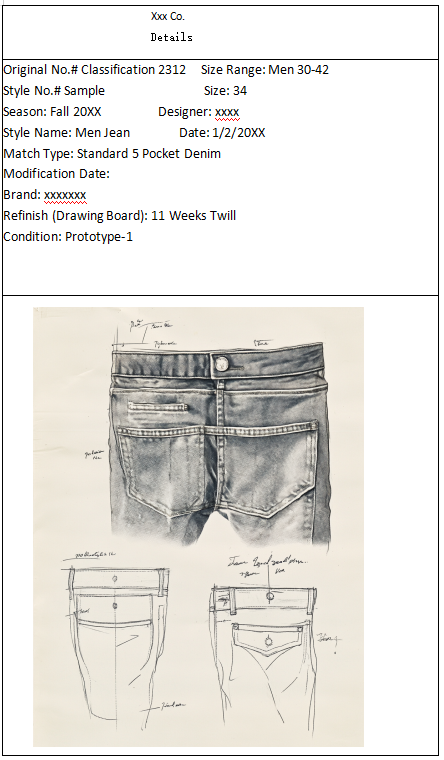

2. Details

- This section provides close-up images or descriptions of key features of the garment, such as buttons, zippers, stitching, or embroidery. The details clarify design specifications and ensure the correct finishing techniques are used.

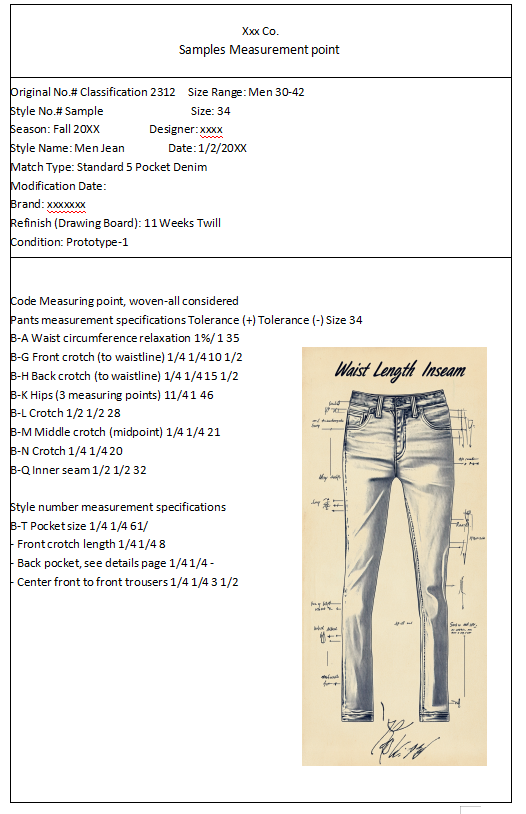

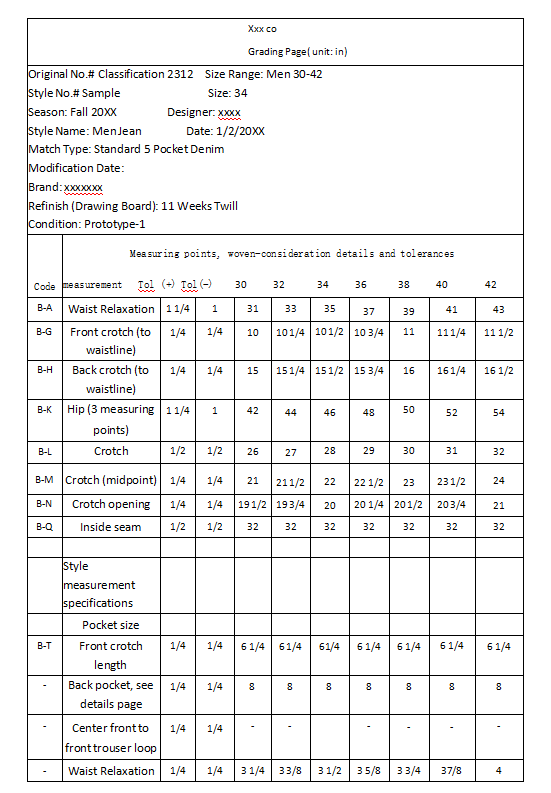

3. Sample Specifications/Measurement Points

- This part of the process sheet lists the specific measurements for each size and the exact points where measurements should be taken on the garment. It ensures the garment is produced to the correct specifications and fits properly across all sizes.

4. Sizing Page

- The sizing page outlines the size range for the garment and provides a size chart. It is essential for manufacturers to know the dimensions for each size, as well as any grading principles for adjustments between sizes.

5. Material List

- The material list is a detailed breakdown of all fabrics, trims, accessories, and other materials required to make the garment. This section also includes information about the composition, color codes, and suppliers for each material.

6. Production Method

- This section provides a step-by-step breakdown of the production process, including the techniques and machinery to be used. It ensures that every garment is made to the desired specifications, whether it requires hand-stitching, machine stitching, or other specialized methods.

7. Labels and Packaging

- Clear instructions on how to attach labels, tags, and any other required markings are provided. This also includes packaging instructions to ensure the garments are stored and shipped correctly, avoiding any damage during transit.

8. Fitting Records and Sample Evaluation

- The process sheet includes records from fitting sessions and sample evaluations. These notes are critical to refining the garment and ensuring that it meets both the designer’s vision and the manufacturer’s standards.

9. Style Summary

- At the top of each page, the style summary provides essential information about the garment. This includes:

- Style number

- Season

- Fabric details

- Size information

- Completion date

- Last modified date

- Sample status

- Development stage

The style summary offers quick reference points for manufacturers and ensures that they are working with the most up-to-date version of the design.

The Role of the Process Sheet in Garment Production

The process sheet is a crucial document that guides manufacturers through the entire garment production process. By clearly defining the materials, measurements, production methods, and other essential information, it helps ensure that the final product aligns with the designer’s vision. This document also helps reduce errors, miscommunication, and delays in production.

For designers, the process sheet is an essential tool for transforming concepts into reality. For manufacturers, it serves as a detailed instruction manual that minimizes ambiguity and ensures the garment is produced accurately.

Conclusion: Why a Process Sheet is Essential for Successful Garment Production

A well-structured process sheet is the backbone of garment production, helping to bridge the gap between designers and manufacturers. By including all the necessary details—such as fabrics, measurements, production methods, and packaging information—the process sheet ensures that the garment meets both design and quality standards.

Whether you’re developing a new collection or refining an existing design, a comprehensive process sheet is vital for ensuring consistency, efficiency, and successful production outcomes. By investing time in creating a detailed process sheet, you can streamline the production process and bring your designs to life with precision and care.