Marker in Garment Manufacturing: Optimizing Fabric Usage for Cost and Quality

🧵 Introduction

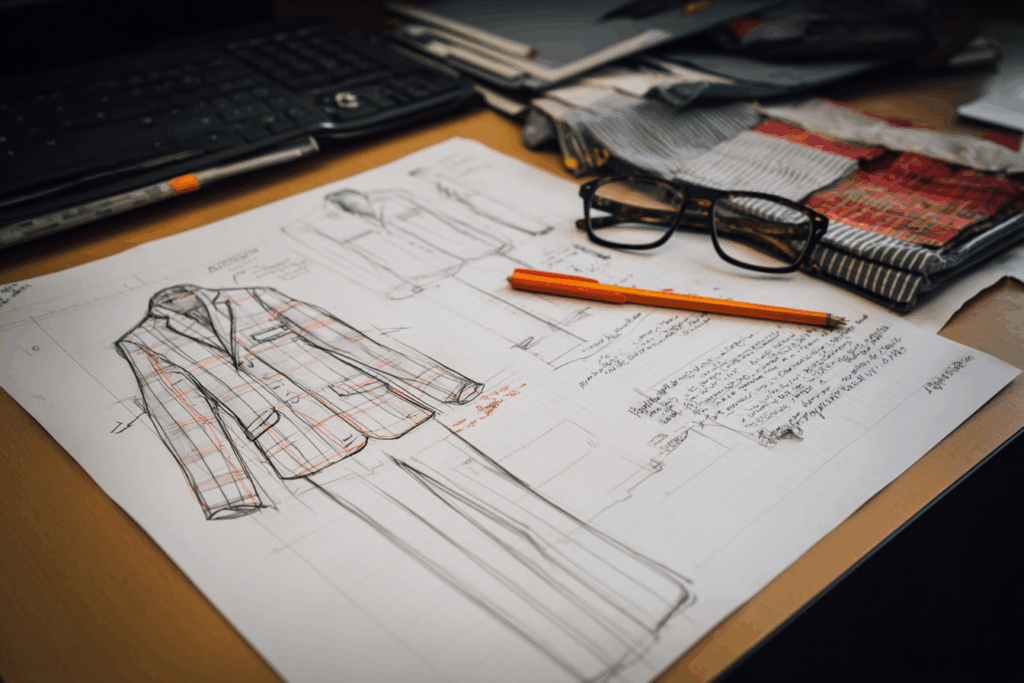

In garment production, the marker is a critical planning tool that outlines how fabric will be cut for manufacturing clothing. It plays a vital role in ensuring cost-efficiency, material utilization, and maintaining the desired appearance and alignment of patterned or solid-color fabrics. A well-prepared marker significantly reduces waste, supports accurate cutting, and directly influences production profitability.

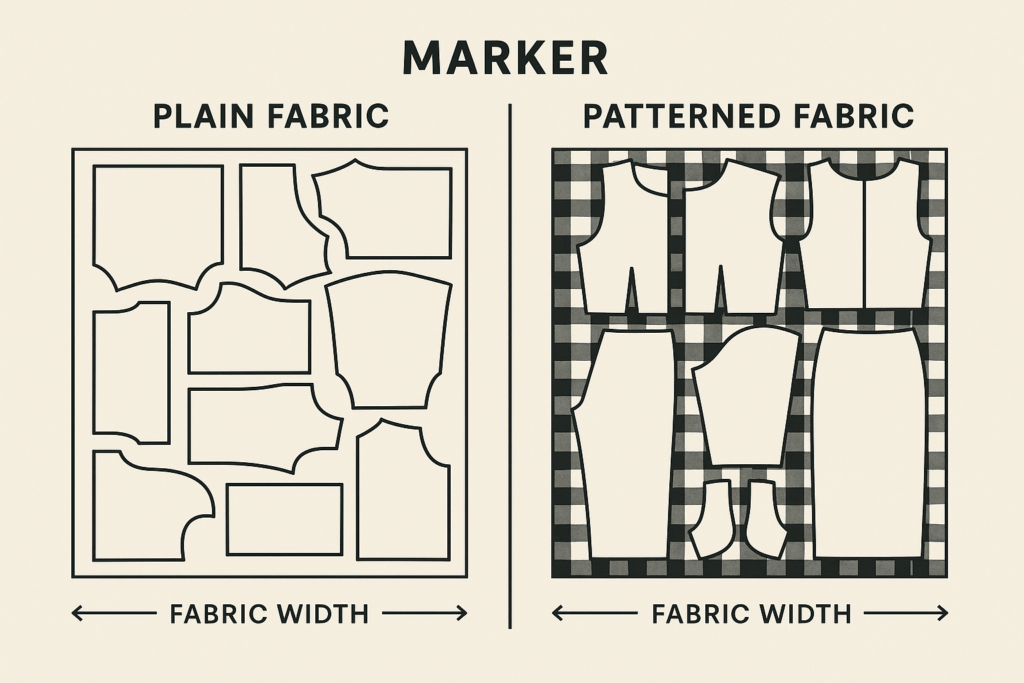

✂️ What Is a Marker?

A marker is a layout plan that shows how each piece of a garment pattern should be placed on the fabric before cutting. Created by technical staff or CAD software, the marker includes:

- Pattern outlines for all sizes and styles to be cut

- Fabric width and length constraints

- Grainline alignment to ensure proper drape and stretch

- Matching of fabric designs, such as stripes or checks

Markers are developed from a cutting instruction sheet (also called a process sheet), which specifies the garment style, fabric type, cutting requirements, and any special instructions.

🧷 Types of Fabrics and Marker Considerations

Different fabrics require different marker strategies:

| Fabric Type | Marker Consideration |

|---|---|

| Plain (Solid Color) | Easier to lay flat. Minimal restrictions. High efficiency. |

| Striped or Checked | Pattern matching is crucial. Requires alignment of motifs. |

| Nap or Pile Fabrics | One-way layout (e.g., velvet) to maintain visual consistency. |

| Twill Fabrics | Directional grains must be considered to avoid skew. |

| Brushed/Raised | Direction of brushing matters for texture consistency. |

For example, plaid or checkered fabrics require the placement of each piece to follow a strict visual pattern for proper alignment. If not aligned properly, garments may appear unbalanced or of lower quality.

🎯 Importance of Marker Planning

Effective marker planning supports:

- Fabric Utilization: Reduces scrap waste and saves cost.

- Cutting Accuracy: Ensures each piece is properly aligned and minimizes fabric defects.

- Design Integrity: Maintains visual harmony, especially in patterned or textured fabrics.

- Production Efficiency: Streamlines workflow from cutting to sewing.

Markers are often optimized using computer-aided design (CAD) systems to create tight layouts and calculate the fabric yield (percentage of fabric used).

🔍 Marker Instructions and Process Sheet

Each cutting instruction sheet includes:

- Garment style number and size breakdown

- Fabric width, roll length, and type

- Any one-way or matching requirements

- Information on directional grain and special placements

Technicians use this information to develop a marker layout that considers:

- Bias or straight cuts

- Size ratios (e.g., S:M:L = 1:2:2)

- Fabric constraints like defects, edges, or roll joining

🧮 Optimizing Cost Through Marker Efficiency

Every centimeter saved through optimized marker placement translates to cost reduction. Even a 1% improvement in marker efficiency can lead to significant savings in bulk production. This makes marker planning a critical cost-control point in the apparel manufacturing process.

📌 Conclusion

A well-designed marker is not just a layout — it’s a bridge between creative design and efficient production. It ensures that fabric is used wisely, garments are cut precisely, and production costs are minimized. Whether for basic T-shirts or high-end suits, marker planning is essential for ensuring quality and profitability in garment manufacturing.