🧵 Piled Fabrics: Understanding Directionality in Velvet, Corduroy, and Fleece Garments

Introduction

Piled fabrics — such as velvet, corduroy, cashmere, cotton fleece, and velveteen — offer rich texture and luxurious visual appeal. However, these fabrics demand precise cutting direction and thoughtful construction methods to avoid color inconsistency, texture misalignment, and garment defects.

What Are Piled Fabrics?

Piled fabrics are textiles with a raised surface (pile) created by loops or cut yarns. The pile reflects light differently based on direction, causing visible shade variation even within the same fabric roll. This makes fabric orientation critical during the cutting and sewing processes.

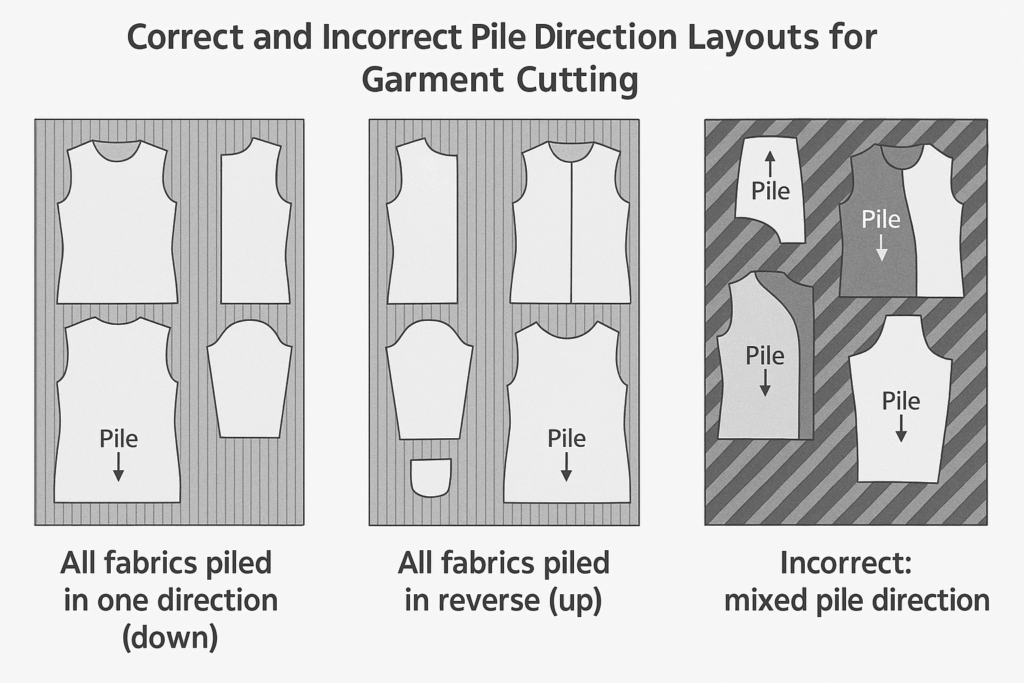

1. 💠 All Fabrics Piled in One Direction (Down)

- Technique: All pattern pieces are aligned with the pile facing down the garment.

- Effect: Produces deep, luxurious color and sheen.

- Best for: Velvet jackets, formal wear, or statement pieces.

- Downside: May fray more quickly over time due to fiber direction.

2. 💠 All Fabrics Piled in Reverse (Up)

- Technique: All pattern pieces are laid with the pile facing upward, often placed at the bottom of the marker.

- Effect: Slightly duller appearance but better wear resistance.

- Best for: Corduroy trousers, children’s wear, and casual outerwear.

- Advantage: Minimizes surface wear on high-friction areas.

3. 💠 Bidirectional Cutting (Mixed Pile Direction)

- Technique: Pattern pieces are laid in both directions to maximize fabric utilization.

- Effect: Increased fabric yield, reduced waste.

- Best for: Low-cost production, single-color garments, or styles where pile difference is subtle.

- Warning: Pieces may look mismatched under lighting or when paired in a coordinated set (like jacket + skirt).

4. ⚠️ Manufacturing Errors: Mixed Pile Within a Garment

Occasionally, a piece may be sewn in reverse pile direction by mistake, causing clear color contrast (especially visible on the front of jackets or coats). This defect is avoidable with experienced cutting and sewing teams, clear labeling, and stringent quality control procedures.

5. Best Practices for Factories and Designers

- Use cutting markers to ensure all pieces align correctly.

- Always label pile direction on the marker and fabric.

- If producing sets (e.g., jacket and skirt), cut from the same batch and direction.

- Train staff on how to identify face and reverse sides.

- Run test garments for high-pile directional fabrics to observe light reflection and consistency.

Conclusion

Cutting piled fabrics the right way ensures consistent appearance, color richness, and durability. While aligning the pile might increase fabric use, it pays off in garment quality and brand reputation. Whether you’re using corduroy, velvet, or fleece, understanding directionality is key to professional fashion construction.