Quality Issues with Knitted Fabrics: Understanding Torque

Knitted fabrics, while praised for their comfort, flexibility, and breathability, are not without their quality challenges. One of the most common structural issues in knitted garments is torque—a twist or spiral distortion that affects the garment’s symmetry and drape. This issue becomes especially noticeable along the side seams, and it can compromise both wearability and aesthetic quality.

🔍 What Is Torque in Knitted Fabrics?

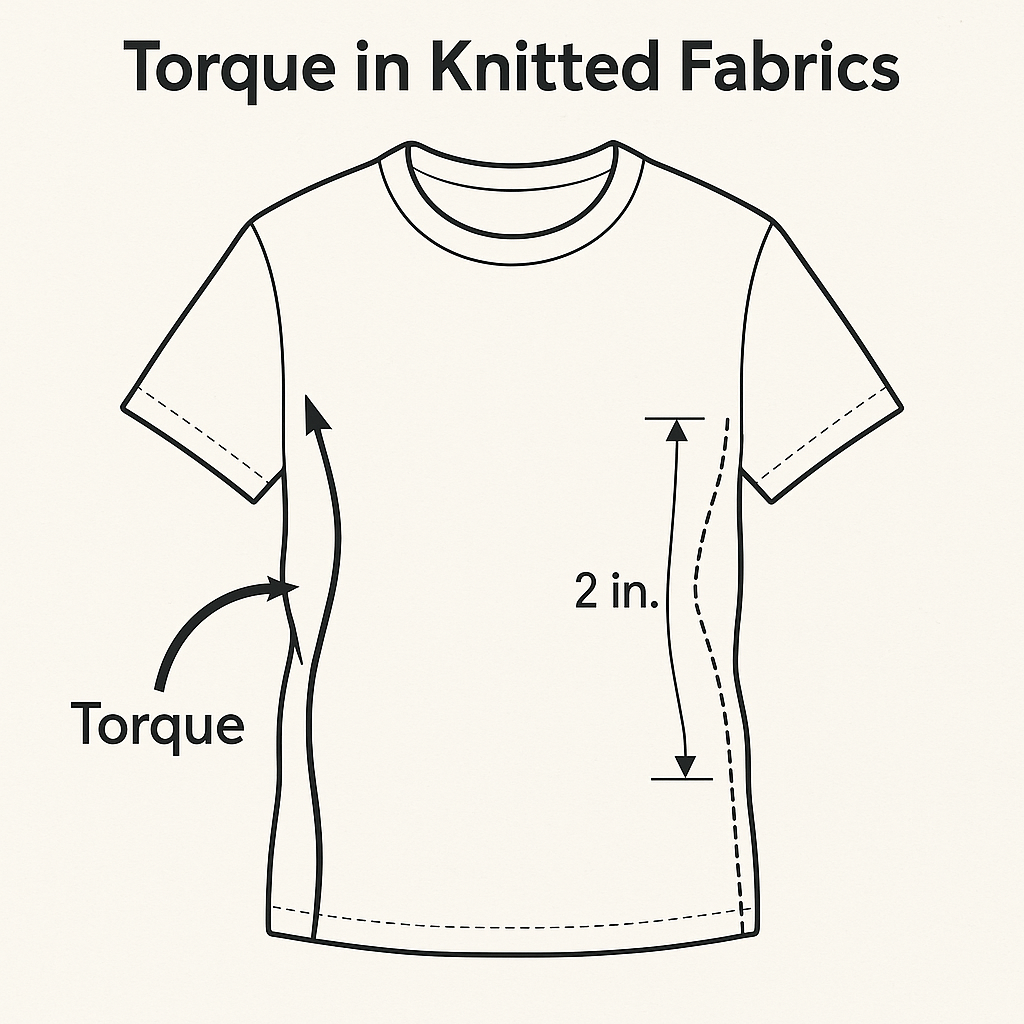

Torque refers to the twisting that occurs when one side seam of a knitted garment moves forward and the other shifts backward. This distortion results in the garment not hanging straight on the body. In severe cases, the front and back panels may become visibly misaligned, causing consumer dissatisfaction and returns.

This is not the same as torque in woven fabrics, which is often introduced during the finishing or dyeing process. In knitted garments, torque is typically embedded during yarn spinning or fabric knitting, long before finishing begins.

🧵 Causes of Torque in Knitted Garments

- Asymmetric Yarn Twist

Knitted fabric yarns, especially single jersey, have built-in twist due to the spinning process. If the twist is not balanced or neutralized, it can cause the fabric to spiral when laid flat or worn. - Improper Yarn Type Selection

Using Z-twist or S-twist yarns without balancing the direction during knitting can cause uneven torque. Some manufacturers use alternating twist directions to mitigate this. - Lack of Garment Pre-Shrinkage

If fabric relaxation is not properly handled before cutting, torque can occur post-laundry, which is often seen by consumers as a defect. - Cutting Direction Issues

Cutting garments without regard to wale and course direction (the vertical and horizontal loops) can worsen torque problems. This is why proper fabric lay planning is essential.

📏 How Is Torque Measured in the Industry?

To maintain quality, the textile industry sets torque tolerances. Most manufacturers consider more than 2 inches (5 cm) of torque deviation at the side seam as unacceptable. This is typically measured after the first wash or dry cycle, mimicking real-life use.

✅ Prevention and Solutions

- Use Balanced Yarn

Select yarns with neutral or low-twist construction. - Double Knitting or Interlock

Use more stable structures like double knit or interlock, which naturally resist torque better than single jersey. - Proper Fabric Relaxation

Let the fabric rest (relax) overnight or longer before cutting. - Pattern Adjustment

Some manufacturers pre-compensate for torque in the pattern itself, especially in T-shirts and stretch tops.

👗 Impact on Garment Appearance

Torque is not always apparent when a garment is on the hanger, but once worn, it can become visible and annoying—especially in garments like:

- T-shirts

- Slim-fit dresses

- Knit tops

- Leggings

In some fashion cases, intentional torque is used as a design element, though this requires careful planning and symmetrical execution.

🧠 Conclusion

Understanding torque in knitted fabrics is crucial for maintaining garment quality, wearability, and customer satisfaction. From yarn choice to pattern cutting and finishing, every step in the production process must be optimized to avoid unwanted twisting and distortion.