🌟 Understanding Raised & Piled Fabrics in Garment Manufacturing

Primary keyphrase: Raised fabrics

Synonyms: piled fabrics, napped fabrics

Related keyphrases: fabric direction in sewing, corduroy layout, velvet garment cutting

Meta Description: Discover how raised or piled fabrics like corduroy, velvet, and fleece affect garment cutting, alignment, and production techniques. Learn why direction matters.

🧵 What Are Raised or Piled Fabrics?

Raised fabrics, also referred to as piled or napped fabrics, feature a soft, elevated surface that gives the fabric a plush texture. These textiles include:

- Corduroy

- Velvet

- Velveteen

- Cashmere

- Cotton fleece

- Certain brushed knits

The pile or nap of the fabric is a result of additional yarn loops or brushed fibers that rise above the base fabric, creating a tactile and visual dimension.

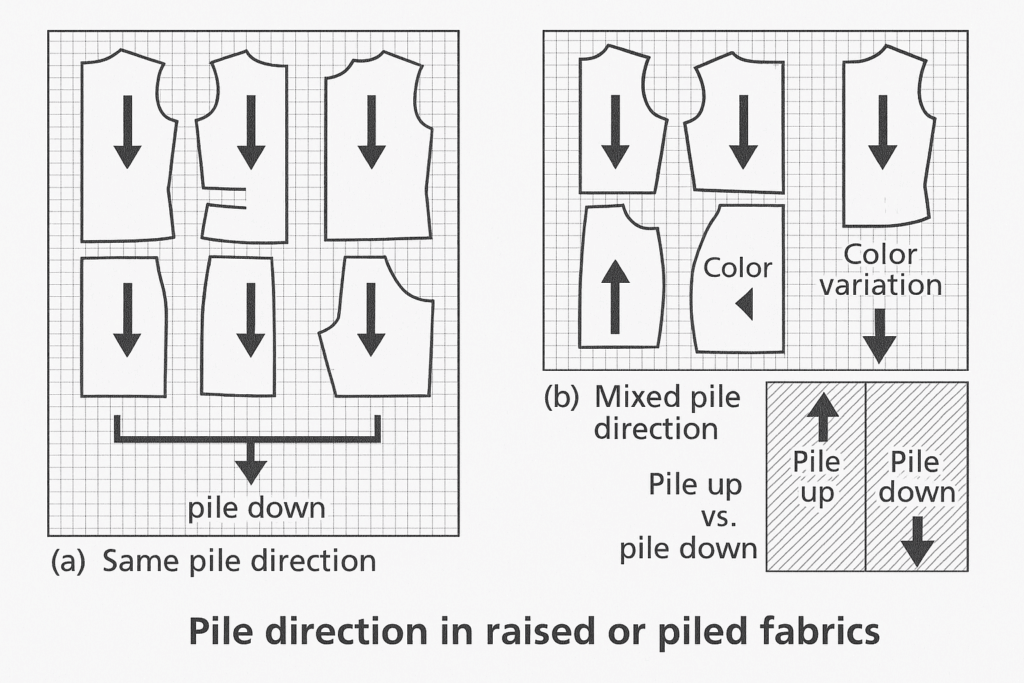

📐 Why Fabric Direction Matters

When working with raised fabrics, the direction of the pile becomes a critical factor in both appearance and production.

- Pile-Up Direction: Produces a lighter, shinier appearance because the light reflects off the pile tips.

- Pile-Down Direction: Appears darker and more matte, as light is absorbed more than reflected.

👉 Mixing pile directions on a single garment creates a mismatched or two-tone effect, even if the fabric is from the same roll.

✂️ Fabric Cutting Rules for Raised Fabrics

To maintain a professional and consistent appearance in the final garment, all pattern pieces must be laid out in the same direction—whether pile-up or pile-down—unless the designer deliberately wants contrast.

Garments commonly affected:

- Suits and jackets made from velvet or corduroy

- Soft outerwear in fleece or brushed cotton

- Trousers, skirts, and hats using cashmere or velveteen

🏭 Impact on Garment Production

1. Increased Fabric Usage

Since all pieces must follow a single direction, fabric cannot be flipped to optimize space. This typically requires 10–20% more yardage than cutting bidirectionally.

2. Cutting Instructions Must Be Clear

Technical packs and cutting instructions should explicitly state:

- “Pile Direction: DOWN” or “Pile Direction: UP”

- “One-way layout required”

- Marker planning for optimal yield while respecting nap

3. Seam & Design Coordination

The grainline must match the nap direction. This prevents visual distortion at side seams, sleeves, or plackets. Even pockets and waistbands must be aligned for color and texture consistency.

🎯 Pro Tip for Fashion Designers

Always test the fabric’s nap in both directions under varied lighting. Use larger swatches when sampling, as small pieces can mislead visual judgment. If unsure, make a prototype first before committing to large-scale production.

✅ Conclusion: Direction Defines Finish

Raised fabrics offer a luxurious touch and depth to garments—but only when cut with directional precision. From velvet jackets to corduroy trousers, mastering nap alignment ensures consistent color, texture, and high-end appeal in your final product.