Sizing Page: A Crucial Element for Accurate Garment Production

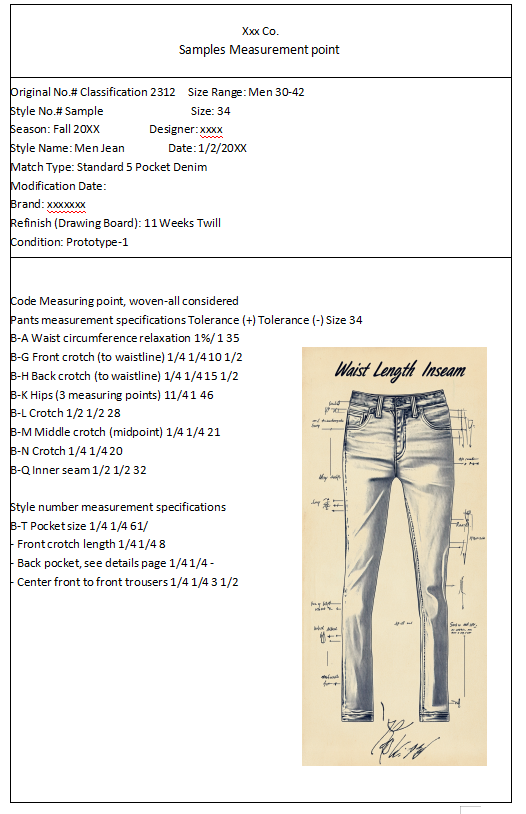

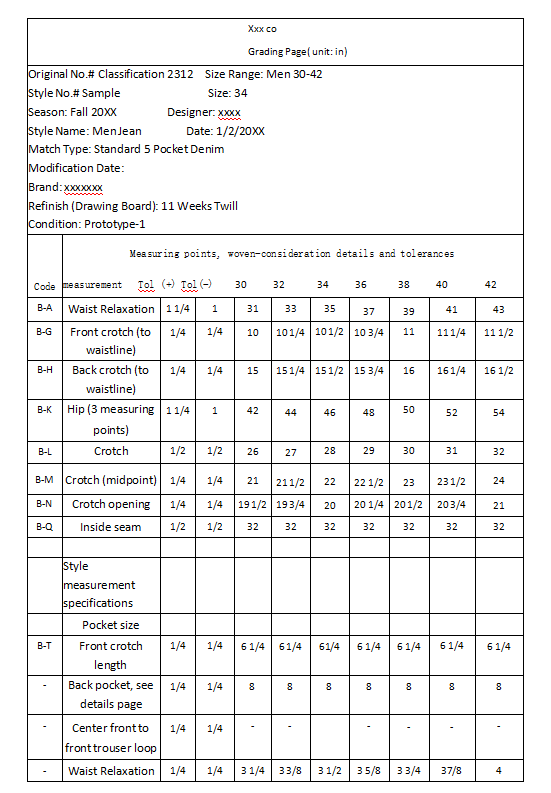

The Sizing Page in a process sheet plays a fundamental role in ensuring that a garment is manufactured to the correct dimensions across different sizes. This page provides the size range for the garment and details the specific measurements for each size, ensuring that the garment fits as intended, from the smallest to the largest size. It also outlines the grading principles used to adjust the garment for different sizes, which is essential for maintaining proportionality and fit across the size spectrum.

Purpose of the Sizing Page

The Sizing Page serves several key purposes in the garment production process:

- Defines the Size Range: It specifies the sizes for which the garment will be produced, ranging from small to large or any other size categories, such as XS to XXL or even custom sizing.

- Provides a Size Chart: The size chart offers the exact measurements for each size, allowing manufacturers to understand the garment’s fit and dimensions.

- Establishes Grading Rules: It explains how the garment measurements will change as the size increases or decreases. Grading ensures that the garment’s proportions are consistent, maintaining the desired fit across different sizes.

- Prevents Fit Issues: A well-documented sizing page reduces the risk of sizing inconsistencies that could result in poorly fitting garments or wasted production time.

Key Elements Included in the Sizing Page

- Size Range

- The size range is the first critical piece of information on the sizing page. It defines the sizes that the garment will be available in, such as:

- XS, S, M, L, XL (Standard sizing)

- 0-14, 16-24 (Plus sizing)

- Petite, Regular, Tall (For varying body types)

- Custom sizes or special measurements if necessary.

- The size range is the first critical piece of information on the sizing page. It defines the sizes that the garment will be available in, such as:

Size Chart

- The size chart is a tabular representation that lists the specific measurements for each size within the defined range. These measurements are critical for ensuring that the garment is produced to the correct specifications and that each size fits well.

Key measurements typically listed in a size chart include:

- Bust: Measured around the fullest part of the chest, under the arms.

- Waist: Measured at the natural waistline, the narrowest part of the torso.

- Hip: Measured at the fullest part of the hips, typically 8–9 inches below the waistline.

- Sleeve Length: Measured from the shoulder seam to the wrist (or desired length).

- Shoulder Width: The distance from shoulder seam to shoulder seam.

- Inseam: The length of the pants, measured from the crotch seam to the hem.

- Center Front Length: Measured from the center of the neck to the hem at the front of the garment.

- Back Length: Measured from the center of the neck to the hem at the back of the garment.

- Armhole: The circumference of the armhole, which is crucial for comfortable sleeve fitting.

Example of a Size Chart:

Size Bust (inches) Waist (inches) Hip (inches) Sleeve Length (inches) Inseam (inches) XS 32 24 34 22 30 S 34 26 36 23 31 M 36 28 38 24 32 L 38 30 40 25 32 XL 40 32 42 26 33 This size chart provides the base measurements that will guide the production of garments in different sizes, ensuring consistency and quality across all units.

Grading Principles

- Grading is the process of scaling the garment’s pattern to different sizes. As a garment is resized, the dimensions change slightly, but the garment’s overall proportion and fit must be maintained. The grading principles outlined in this section explain how the measurements should be adjusted for each size.

Example of grading principles:

- Bust Measurement: Increase by 1 inch for each size.

- Waist Measurement: Increase by 0.5 inches for each size.

- Hip Measurement: Increase by 1 inch for each size.

- Sleeve Length: Increase by 0.25 inches per size.

- Inseam Length: Increase by 0.5 inches for each size.

The grading rules ensure that the proportions of the garment are maintained across the size range. For example, a bust measurement might be increased by 1 inch for each size, but the grading rules should also account for changes to other dimensions like sleeve length or hip measurement to keep the garment balanced and comfortable.

Tolerance Levels for Each Measurement

- Tolerance levels indicate how much variation is acceptable for each measurement. In production, slight discrepancies in measurements may occur, but these should remain within specified tolerance ranges to ensure a well-made garment.

For example:

- Bust: ±0.5 inches

- Waist: ±0.25 inches

- Hip: ±0.5 inches

- Inseam: ±0.75 inches

- Sleeve Length: ±0.5 inches

Tolerance levels allow manufacturers some flexibility while ensuring that the final product meets the designer’s fit standards. These levels help accommodate small variations during production and still maintain an acceptable fit.

Fit Descriptions for Each Size

- The fit of a garment refers to how closely it follows the body, and different sizes may require different fit descriptions. For example, a size medium might have a “regular fit” while a size large could require a “looser fit” to accommodate different body types.

The Sizing Page might include information on the type of fit for each size:

- Slim Fit: A closer-fitting garment that contours to the body.

- Regular Fit: A standard, more relaxed fit that’s not too tight and not too loose.

- Loose Fit: A garment with a relaxed, oversized style.

This ensures that manufacturers understand the intended fit for each size and make the necessary adjustments during production.