Technical Face: Understanding the Front Structure of the Plain Stitch

Meta Description: The technical face refers to the front side of a fabric created using the plain stitch. Learn how this structure is formed, its applications, and how it impacts fabric quality and appearance.

What is a Technical Face?

The technical face of a fabric is the front side that is created using a plain stitch (also known as the basic stitch or simple stitch). This is the side of the fabric that typically appears smooth, even, and uniform. The plain stitch structure is formed when the warp and weft threads are interwoven in a simple alternating over-and-under pattern, creating a basic weave that is the foundation of most woven fabrics.

The technical face is important because it determines the aesthetic appearance and texture of the fabric, making it key to understanding the fabric’s use and durability in garment construction.

Key Features of the Technical Face

✔ Smooth Appearance: The front side of the fabric is usually even and flat, with no visible threads protruding from the surface.

✔ Simple Weave Structure: The plain stitch creates a uniform grid of threads that forms a balanced weave, providing the fabric with strength and stability.

✔ Durable: The alternating weave makes it a strong structure, often used in basic fabrics like cotton, linen, and polyester.

✔ Commonly Used: Plain stitch is the most commonly used weave for creating shirts, pants, and upholstery fabric.

How the Plain Stitch Forms the Technical Face

The plain stitch is the most basic weaving method, where the warp (vertical) and weft (horizontal) threads are interlaced in an alternating pattern. This simple over-and-under weave ensures that the fabric is tight and durable, which is essential for creating everyday fabrics.

The technical face of the fabric refers to the side where the weft threads cross over the warp threads. This side usually has a neat, smooth finish that is ideal for the front-facing appearance of garments and products. The back side of the fabric, in contrast, might have a slightly rougher or more textured appearance due to the interlacing of the threads.

Applications of the Technical Face in Fabric Production

The technical face plays an important role in the appearance and application of woven fabrics. Here are some common applications:

📌 Shirts & Casual Wear: The smooth technical face created by plain stitching makes it ideal for comfortable and durable garments like shirts and blouses.

📌 Upholstery: Plain weave fabrics, with their balanced structure, are also popular for upholstery fabrics, where strength and durability are essential.

📌 Home Textiles: From bed linens to curtains, the smooth technical face provides the clean, neat look that is desired in home décor fabrics.

📌 Uniforms: The resilient and strong plain stitch is a common choice for work uniforms and activewear.

Advantages of the Technical Face in Fabrics

1. Durability and Strength

The plain weave is known for its strength because it creates a tightly woven fabric with good resistance to wear and tear. This makes it a long-lasting choice for garments that will endure heavy use.

2. Versatility

The technical face can be used for a variety of purposes, from casual clothing to high-performance fabrics, providing both functionality and aesthetic appeal.

3. Easy to Maintain

Since plain weave fabrics are simple in construction, they are also easy to care for, often being machine washable and resistant to shrinkage or wrinkling.

4. Affordable Fabric Option

Plain weave is one of the most cost-effective weaving methods, making it a popular choice for manufacturers who need affordable yet durable fabrics for mass production.

Technical Face vs. Back Face

| Feature | Technical Face (Front) | Back Face (Reverse) |

|---|---|---|

| Appearance | Smooth, neat, even | Slightly rough or textured |

| Thread Visibility | Warp and weft interlaced evenly | Threads may be more visible |

| Use | Visible side in finished garments | Not usually visible |

| Strength | Strong and durable | Similar strength |

| Texture | Flat and uniform | Less smooth |

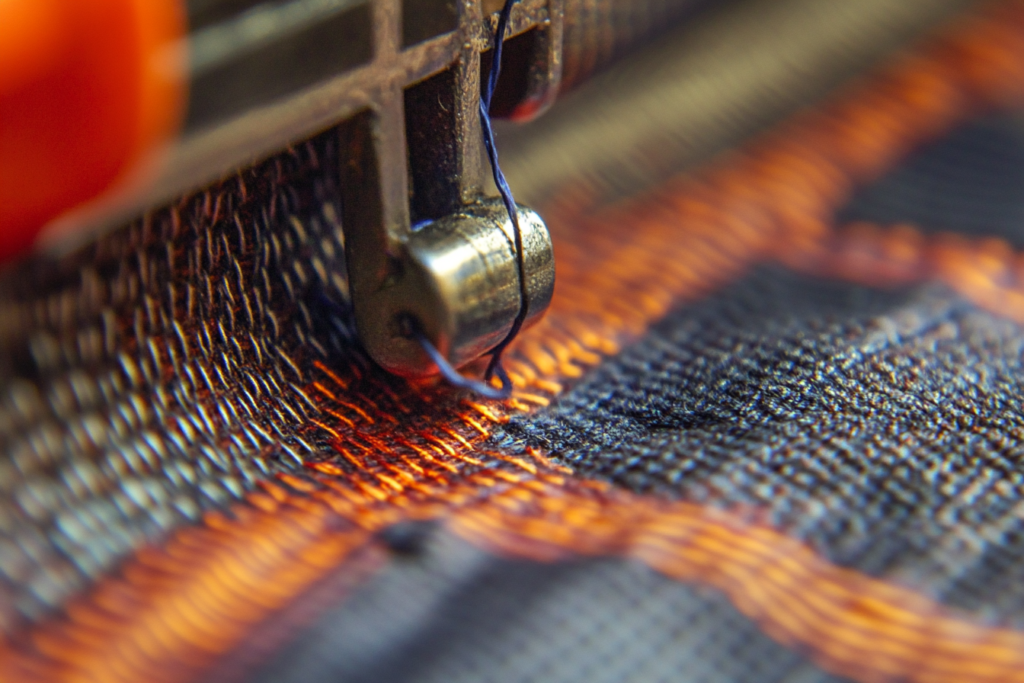

Illustration of the Technical Face of Plain Stitch Fabric

Below is an illustration showing the front side (technical face) of a fabric woven using the plain stitch. It highlights the even, smooth structure of the fabric’s surface, with horizontal rows of threads clearly visible. The back side of the fabric shows how the threads are less organized, creating a slightly rougher appearance.

Conclusion: The Importance of the Technical Face in Fabric Design

The technical face of a fabric is vital in determining its appearance, durability, and functionality. The plain stitch structure creates a strong, uniform, and smooth fabric that can be used in a variety of garments and textiles, from casual wear to home décor.

By understanding the importance of the technical face and the plain stitch, manufacturers and designers can create high-quality fabrics that offer both aesthetic appeal and practical functionality.