Technical Flat: The Blueprint for Garment Design and Production

Meta Description: A technical flat is an accurate, proportioned sketch of a garment, showing its front, back, and sometimes side views. Learn how technical flats are used in fashion design and garment production.

What is a Technical Flat?

A technical flat is a detailed, proportioned sketch of a garment, providing a clear and accurate visual representation of the design. It serves as a blueprint for garment production and is a key element in the specification sheet used by designers, pattern makers, and manufacturers.

A technical flat typically includes:

- Front and back views of the garment

- Side view if necessary to show additional details

- Accurate proportions of the garment

- Design elements such as stitching, trims, and finishes

These sketches are used to communicate the design to the production team and ensure that the final garment matches the designer’s vision.

Key Features of a Technical Flat

✔ Proportioned and Accurate Sketches: Shows the garment in correct proportions and design details.

✔ Multiple Views: Includes front, back, and sometimes side views for a comprehensive understanding.

✔ Design Details: Highlights stitching, trims, finishes, and fabric types.

✔ No Fashion Model: Unlike fashion illustrations, technical flats focus on the garment itself rather than how it looks on a model.

✔ Used in Spec Sheets: Placed on the front page of the specification sheet for garment production.

Why Are Technical Flats Important?

1. Clarify Design Details

Technical flats are the visual reference for garment construction. They help manufacturers understand exactly how the garment should look, down to the details of stitching, closures, and pocket placements.

2. Facilitate Communication

These flats act as a language between the designer and the production team. By using accurate sketches, designers can avoid misunderstandings that may arise from verbal descriptions alone.

3. Guide Production

A technical flat is the starting point for creating the garment’s pattern. It helps the team know what to expect during cutting, sewing, and finishing processes.

4. Provide a Design Blueprint

They ensure that every garment is produced according to the exact design specifications, making them essential for maintaining consistency across multiple items in the production line.

How Technical Flats Are Created

1. Initial Design Sketch

The first step in creating a technical flat is the design sketch of the garment, showing the key features, silhouette, and proportions. This sketch is typically done by the designer or fashion illustrator.

2. Creating the Flat Drawing

Once the initial sketch is approved, the designer or technical designer will create a flat drawing. This involves straightening out the sketch and showing it in two dimensions, with accurate proportions.

3. Adding Design Details

The flat sketch will then have design details added, such as seams, stitches, trims, buttons, zippers, pleats, and other garment features. This is a crucial part to communicate how the garment should be constructed and finished.

4. Including Measurements

Technical flats often include measurements for key garment areas such as the bust, waist, hips, and length. This helps provide clarity on the exact size and fit of the garment.

5. Finalizing the Flat

After all the details are added, the final technical flat is placed on the specification sheet and shared with the manufacturing team. It serves as the blueprint for production.

Technical Flats vs. Fashion Illustrations

| Feature | Technical Flat | Fashion Illustration |

|---|---|---|

| Purpose | To communicate garment design for production | To showcase the garment’s look and feel on a model |

| Detail | Focuses on garment’s construction details | Focuses on overall aesthetic and style |

| Views | Shows front, back, and side views | Typically shows only the front of the design |

| Accuracy | Highly accurate with specific measurements | More artistic and expressive |

| Used by | Designers, pattern makers, manufacturers | Designers, marketing teams, clients |

How to Create a Technical Flat: A Step-by-Step Guide

Meta Description: Learn how to create a technical flat—a key tool for designers and manufacturers. This step-by-step guide will help you craft accurate, detailed sketches for garment production.

What is a Technical Flat and Why Do You Need One?

A technical flat is a two-dimensional, accurate sketch of a garment that represents its front, back, and sometimes side views. Unlike a fashion illustration, which shows a garment worn by a model, the technical flat focuses on details that are essential for garment production. It provides clear instructions for pattern makers and manufacturers to follow, ensuring that the design is correctly interpreted and the garment is constructed accurately.

Creating a technical flat is a crucial skill for fashion designers, as it helps bridge the gap between concept design and actual garment production.

Step-by-Step Guide: How to Create a Technical Flat

Here’s how to create an effective technical flat:

Step 1: Prepare Your Garment Design Concept

Before you start drawing, you should have a clear idea of the garment’s design. This includes:

- Silhouette (e.g., A-line, straight-leg, oversized, etc.)

- Key features (e.g., collars, pockets, pleats, buttons)

- Fabric choice (e.g., cotton, silk, leather)

- Details (e.g., trims, zippers, stitching)

If possible, sketch a basic fashion illustration to get a feel for the garment’s overall design before moving to the technical flat stage.

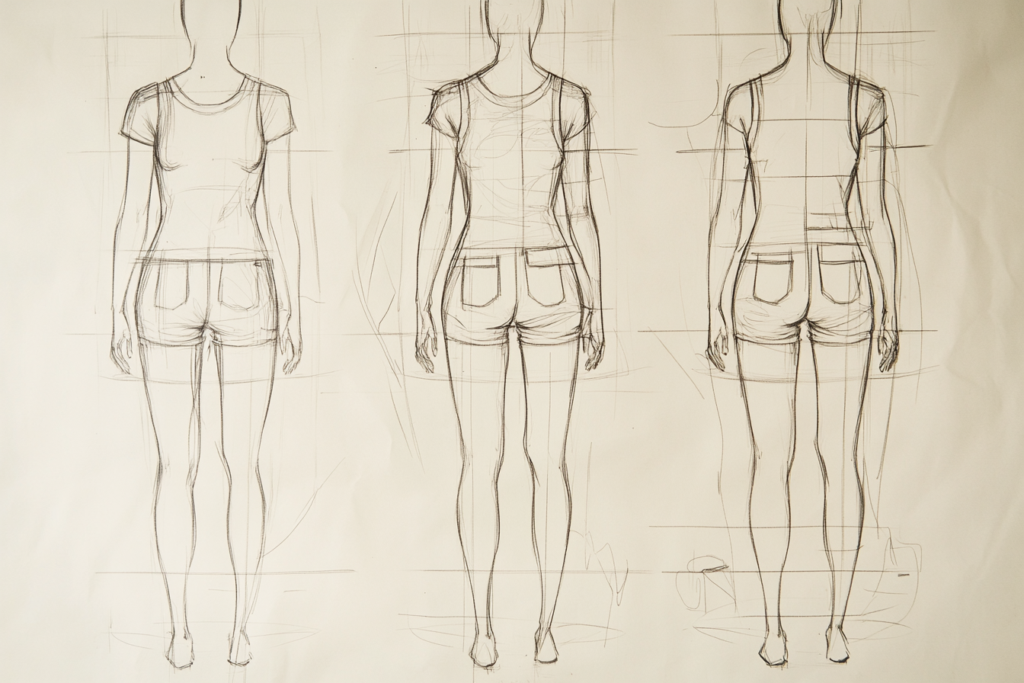

Step 2: Draw the Basic Outline of the Garment

Start by drawing the basic shape of the garment. You should use correct proportions, so the drawing accurately represents how the garment will fit and look. A standardized figure is often used as a template for the front and back views.

- For tops, include details like the neckline and armholes.

- For bottoms, focus on the waistband, side seams, and hem.

- Side views can be drawn if necessary to show additional design elements like pleats or darts.

Step 3: Add Design Details

This is the most important part of the process, as it conveys all the specific features that make the garment unique. Add:

- Stitching lines (e.g., topstitching, seam lines, or decorative stitching)

- Pockets, zippers, and button placements

- Collars, cuffs, and darts

- Trims, such as lace, bias tape, or appliqué elements

- Fabric textures, if needed (you can use color or cross-hatching for different materials)

Step 4: Use Annotations for Measurements and Details

Once the basic drawing is complete, you should add any measurements or specific construction details. These could include:

- Chest, waist, and hip measurements

- Length from shoulder to hem, inseam for pants, etc.

- Fabric types and colors

- Finishing techniques (e.g., double-stitched seams, rolled hems)

These annotations ensure that everyone involved in the production process understands how to cut, sew, and finish the garment.

Step 5: Add Front, Back, and Side Views

If your garment design includes details that need to be viewed from the side or back, make sure to include these views. Each view should match up correctly with the corresponding part of the garment.

- The front view shows the overall design and features.

- The back view displays additional features such as back closures, back pleats, or pockets.

- The side view can be important for garments like jackets, where sleeve design or side vents are significant.

Step 6: Finalize and Present the Technical Flat

Once all the details are added and properly aligned, your technical flat is ready to be finalized. Double-check all annotations, measurements, and details for accuracy.

Ensure your flat is clear, neat, and easy to understand for those in the production process. The flat should be in black and white with no model illustrations—this is strictly about the garment construction.

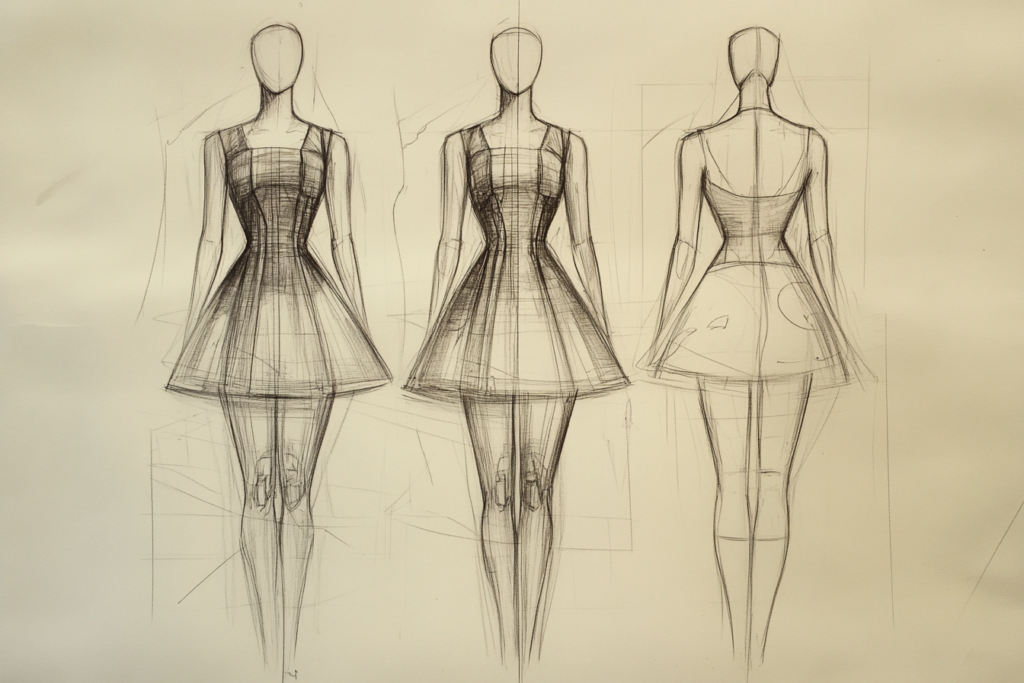

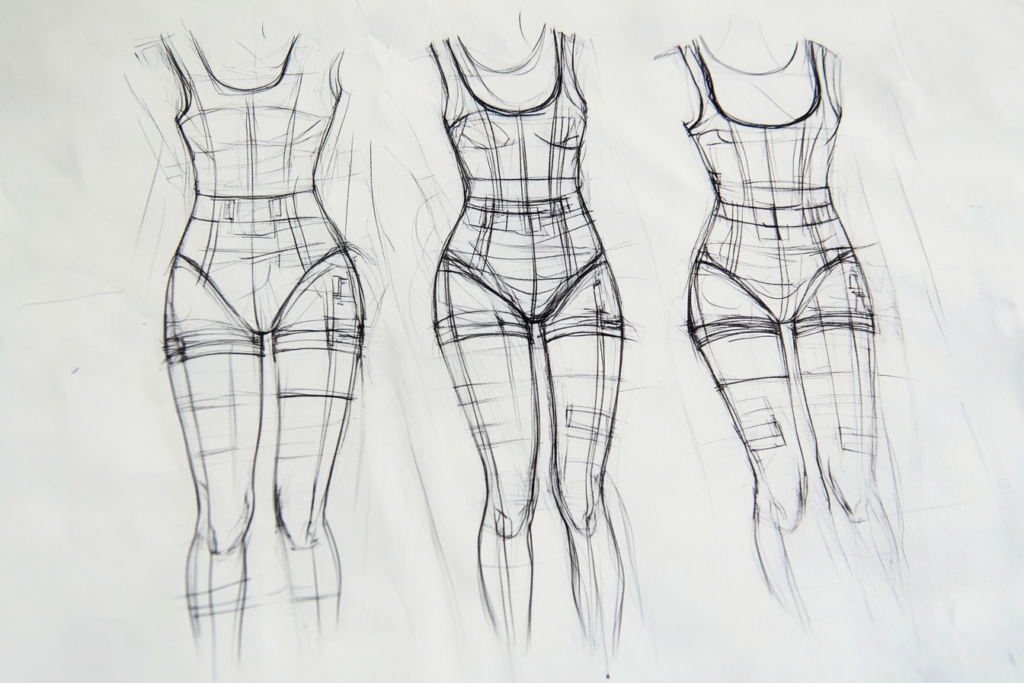

Illustration: Creating a Technical Flat

Here’s an example of what a technical flat might look like, with front, back, and side views showing various design elements:

- Front View: Main features of the garment, like buttons, necklines, and pockets.

- Back View: Any features such as zippers, vents, or back pleats.

- Side View: Detailed view of side seams, darts, or pleats.

- Annotations: Detailed notes on measurements, fabric choice, and construction.

please generate illustrion

ChatGPT said:

Importance of Technical Flats in Fashion Production

1. Clear Communication Between Designers and Manufacturers

Technical flats ensure that all design details are communicated accurately to the manufacturing team. Without a technical flat, misinterpretation of design details can result in production delays or incorrect garment construction.

2. Quality Control

A well-made technical flat provides a standardized visual guide for quality control, ensuring that every garment is produced according to the designer’s specifications.

3. Time-Saving in Production

Technical flats speed up the design-to-production process by providing precise, ready-to-use sketches. Instead of relying on multiple back-and-forth revisions or unclear verbal instructions, the flat serves as a clear reference for everyone involved.

Where Are Technical Flats Used?

1. Fashion Design

Technical flats are essential tools for fashion designers, as they serve as the main communication tool between the designer and the production team.

2. Pattern Making

Pattern makers use technical flats to translate the design into flat patterns that can be used to cut the fabric for production.

3. Manufacturing

In the manufacturing process, the technical flat serves as a guide for production, ensuring each garment is produced according to the correct specifications.

4. Marketing and Sales

Technical flats are often used in sales presentations to show potential clients or buyers how the finished garment will look. They help sales teams showcase the product and sell the design.

Conclusion: The Essential Role of Technical Flats in Fashion Production

Technical flats are an indispensable part of the fashion design and production process. They serve as blueprints, ensuring that garments are produced according to the designer’s exact specifications. By accurately depicting the front, back, and side views, as well as including measurements, materials, and construction details, technical flats guide the entire manufacturing process, from pattern making to final production.

Whether you’re a designer, pattern maker, or manufacturer, understanding the importance of technical flats is crucial for ensuring that designs are accurately interpreted and successfully produced.