The Right Fabric: Matching Materials to Design, Quality, and Production

🧵 Why Fabric Choice Is Critical in Garment Manufacturing

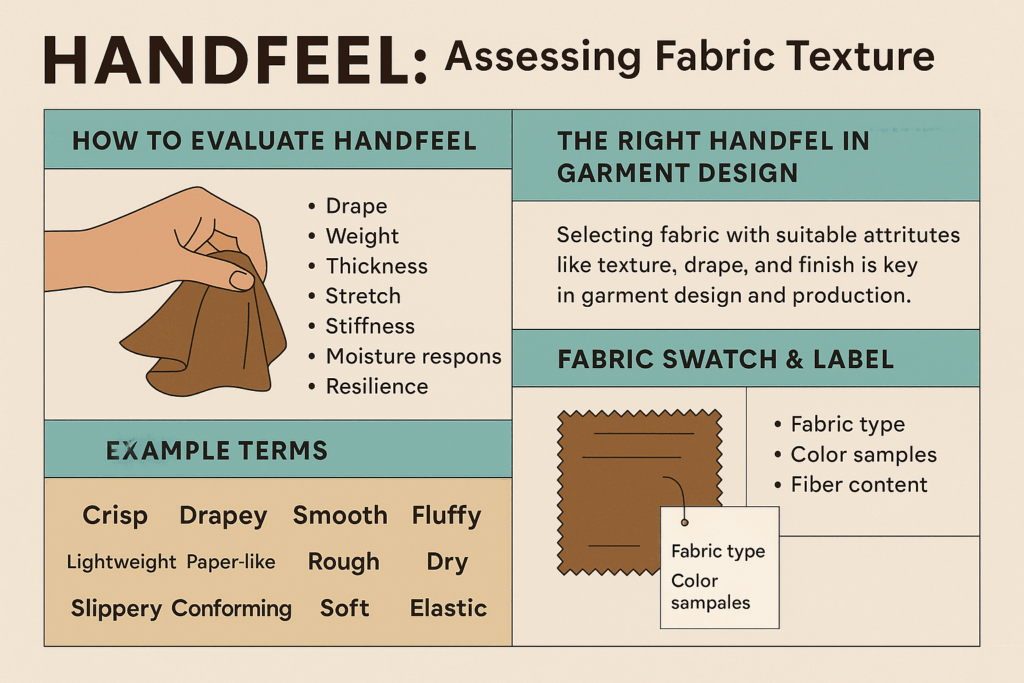

Fabric quality is one of the most visible indicators of overall garment quality. Even the most innovative or creative designs will fall short if the wrong fabric is selected during production. Each fabric has unique characteristics that affect appearance, construction, durability, and cost—making fabric selection a crucial decision at both the design and production planning stages.

🪡 Fabric Behavior & Garment Suitability

Different fabrics behave differently—and this directly impacts fit, drape, and finishing.

| Fabric Type | Key Properties | Suitable Garment Types | Unsuitable Uses |

|---|---|---|---|

| Stiff cotton twill | Holds shape, structured | Pants, jackets, uniforms | Draped dresses or flowy tops |

| Silk charmeuse | Lightweight, slippery, luxurious | Eveningwear, scarves | Rigid garments, casual trousers |

| Linen | Breathable, prone to wrinkles | Summer shirts, dresses | Heavy-duty workwear |

| Polyester blends | Easy-care, cost-efficient | Uniforms, casualwear | High-end tailoring |

| Stretch jersey | Flexible, body-conforming | T-shirts, leggings | Crisp formalwear |

📌 Choosing the wrong fabric can distort silhouette, compromise wearability, or increase production cost due to added complexity.

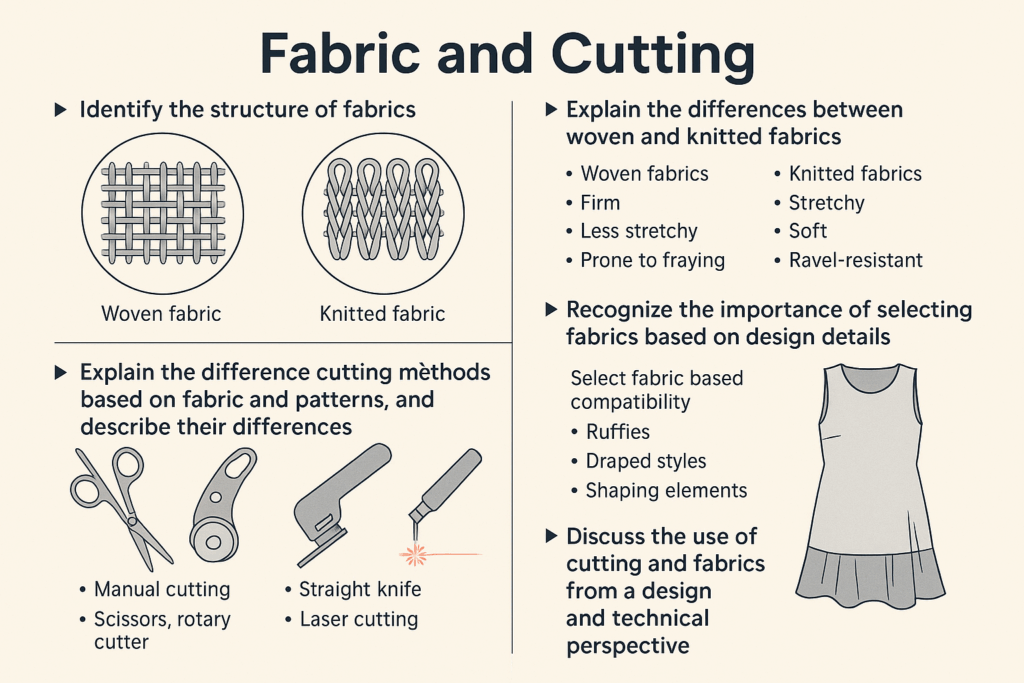

✂️ Fabric and Cutting: A Two-Way Relationship

Not all fabrics are cut the same. Depending on the material’s stretch, structure, or surface finish, cutting methods must be adapted to avoid quality issues:

🔸 Fabric Types Requiring Special Cutting:

- Silks and slippery synthetics: May require layered cutting or anti-slip tools

- Sheer fabrics: Demand precision to avoid edge distortion

- Heavy denim or canvas: Need sharp industrial cutting blades

- Plaids and patterns: Require alignment for visual consistency

✂️ Cutting errors can result in uneven seams, mismatched patterns, or visual distortion—affecting both aesthetics and wearability.

📋 Planning Fabric in Production Specifications

Fabric selection should be clearly outlined in the production specification sheet (tech pack), including:

- Fabric name and supplier

- Fiber content and weight (GSM)

- Shrinkage and stretch behavior

- Special treatments required (e.g., preshrinking, stabilizing)

- Required cutting method (e.g., laser cut, manual, layered)

- Acceptable tolerance for pattern distortion

✅ Early communication between designers, pattern makers, and production teams reduces costly mistakes.

🧷 Design Considerations: Beyond Aesthetics

While the visual impact of fabric is important, designers must also account for:

- Production feasibility: Can the fabric be processed within budget and time constraints?

- Sewing complexity: Will it fray, slip, or stretch during assembly?

- Final function: Will it meet the wearer’s comfort, durability, and maintenance expectations?

🔍 Garments should not only look right, but also function correctly in real-world use.

🌟 Summary

Choosing the right fabric is more than a creative choice—it’s a strategic decision that impacts the entire garment lifecycle, from design to production to the final consumer experience. Designers and production teams must work closely to ensure fabric matches the design intent, cost goals, and technical requirements of the garment. By considering cutting techniques, material properties, and construction limitations from the beginning, brands can create better garments, reduce production errors, and increase customer satisfaction.