Uneven Checks in Garment Design: Alignment, Applications, and Cutting Techniques

Introduction: What Is Uneven Check Fabric?

Uneven check fabric refers to a woven textile featuring checks that differ in size, shape, or spacing, creating an asymmetrical or directional pattern. These fabrics are commonly used in fashion garments like jackets, skirts, and tailored suits to produce bold, modern aesthetics. Designers love using uneven checks for their ability to draw visual interest and create body-enhancing illusions.

Key Characteristics of Uneven Checks

- Asymmetrical pattern repeat: Unlike uniform checks, the repeating blocks in uneven checks are not mirrored equally.

- Directional appearance: The checks often lean or stretch in one direction, which must be considered when cutting and assembling garments.

- Visual dominance: Uneven checks often become the focal point of the garment design.

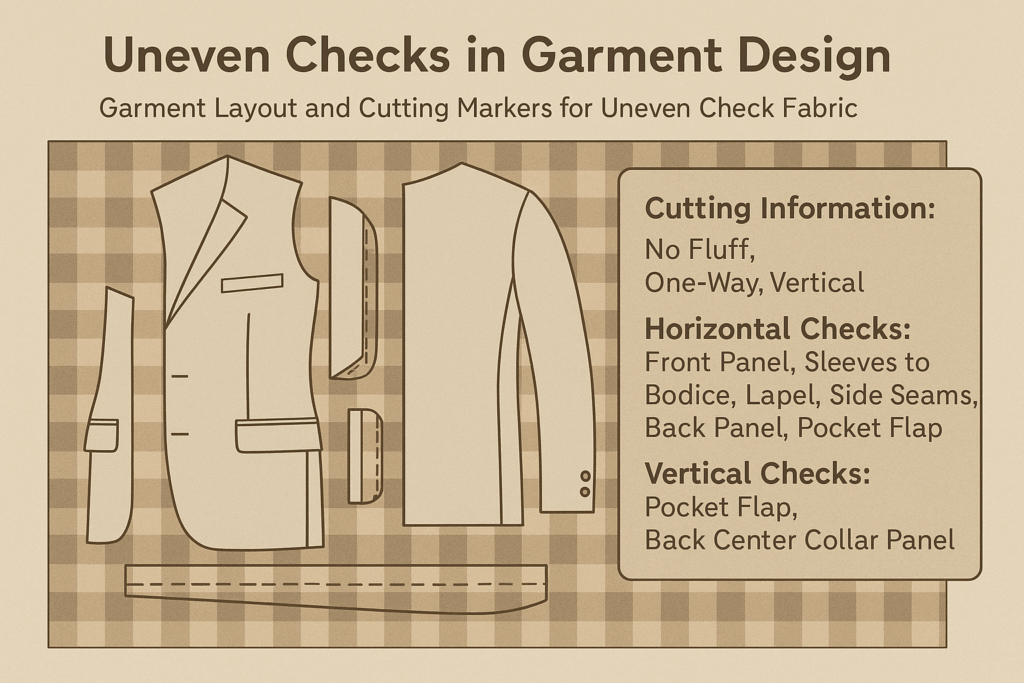

Cutting Techniques and Marker Instructions

Proper handling of uneven check fabrics begins with clear and precise cutting instructions. Cutting must account for the directionality of the pattern to ensure visual balance and symmetry across garment sections.

Important Guidelines:

- One-way cutting only: All pattern pieces must be cut in the same fabric direction to maintain consistency.

- Visual alignment: Dominant check lines must align at key junctions: side seams, lapels, back panels, and pockets.

- Fabric planning: Uneven checks often require more fabric to ensure alignment, impacting production cost and fabric utilization.

Example Cutting Instruction (As seen in industry sheets):

mathematicaCopyEditCutting Information: No Fluff, One-Way, Vertical

Horizontal Checks: Front Panel, Sleeves to Bodice, Lapel, Side Seams, Back Panel, Pocket Flap

Vertical Checks: Pocket Flap, Back Center Collar Panel

Garment Types That Use Uneven Checks

- Tailored jackets and suits: Benefit from directional control and bold visual impact.

- Pleated skirts: The check flows naturally around the body with minimal alignment requirements.

- Outerwear: Adds texture and asymmetry to coats or trench coats.

Sewing Considerations for Uneven Checks

Sewing uneven checks requires higher craftsmanship. Matching dominant lines across seams is critical for producing a quality garment. Specialized factories often handle garments requiring detailed check alignment.

Common Mistakes to Avoid

- Ignoring fabric direction: Leads to mismatched patterns and poor aesthetics.

- Assuming symmetry: Even when checks look similar, measuring the repeat is essential.

- Insufficient marker planning: Increases fabric waste and misalignment risk.

Conclusion

Designing with uneven check fabric offers exciting visual possibilities but demands precision in cutting and sewing. When used correctly, this pattern transforms simple garments into premium fashion pieces. However, it requires designers, cutters, and sewers to collaborate with precision and follow strict instructions for a successful outcome.