🧵 Why Fabric Selection and Cutting Technique Define Garment Quality

Introduction

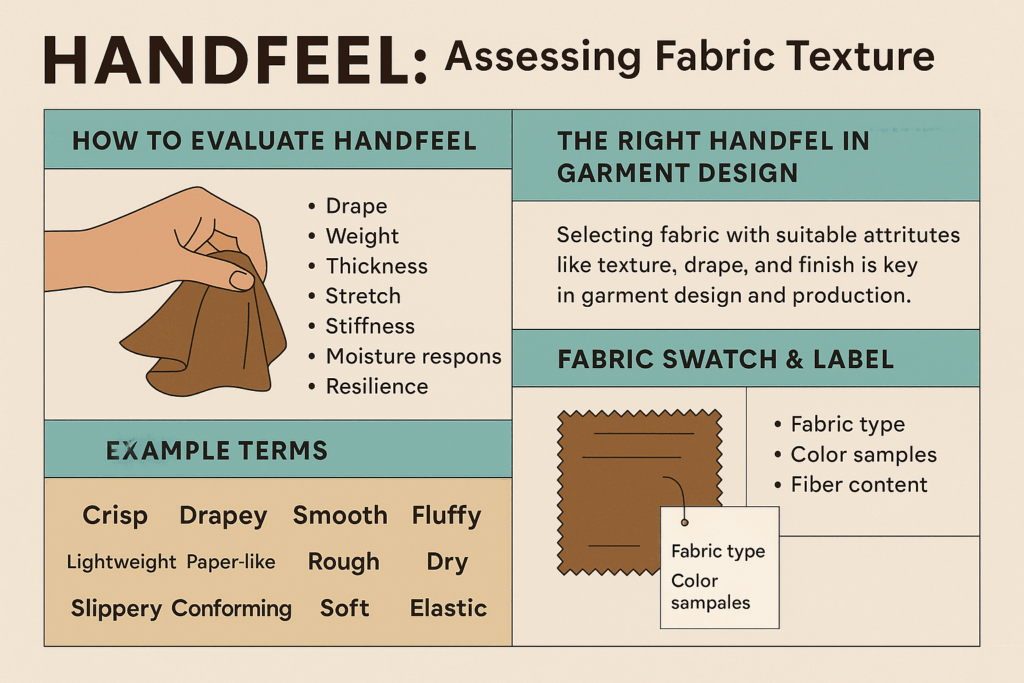

Fabric is not just a raw material — it’s the foundation of garment quality. From the feel of the fabric to the way it holds shape after washing, the material chosen directly influences how a product looks, fits, and performs. Whether you’re a fashion designer, production manager, or factory technician, understanding how to match fabric type with design intention is critical to producing functional, attractive, and cost-effective clothing.

Understanding Fabric as a Quality Indicator

The texture, behavior, and stability of a fabric determine more than just aesthetics — they define performance, comfort, and longevity. Some of the key quality factors impacted by fabric selection include:

- Durability and wear resistance

- Shape retention after stretching or washing

- Colorfastness and shrinkage

- Ease of sewing and finishing

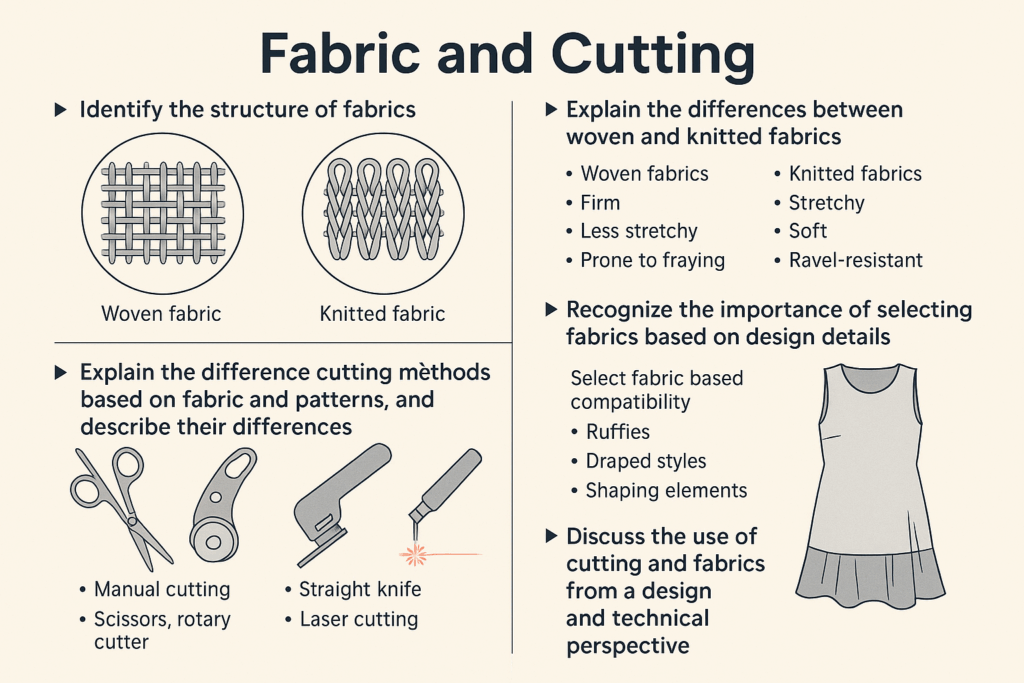

Woven vs. Knitted Fabrics: What’s the Difference?

| Property | Woven Fabric | Knitted Fabric |

|---|---|---|

| Structure | Interlaced yarns (warp & weft) | Interlooped yarns |

| Stability | Less stretch, holds shape well | More flexible, stretches easily |

| Appearance | Crisp, structured | Soft, casual |

| Use Cases | Shirts, trousers, coats | T-shirts, sportswear, loungewear |

| Cutting Requirements | Straight grain important | Curling edges; needs special handling |

Each fabric type brings its own challenges to layout, alignment, and cutting techniques. For instance, knitted fabrics may curl at the edges and require underlay stabilizers, while woven fabrics require precise grain alignment to maintain silhouette.

Why Cutting Instructions Matter

Cutting instructions serve as the bridge between design and production. A well-developed cutting plan ensures:

- Efficient fabric utilization (reduced waste)

- Accurate pattern placement (better alignment and appearance)

- Clear communication between the designer and production team

- Lower production cost and consistent garment sizing

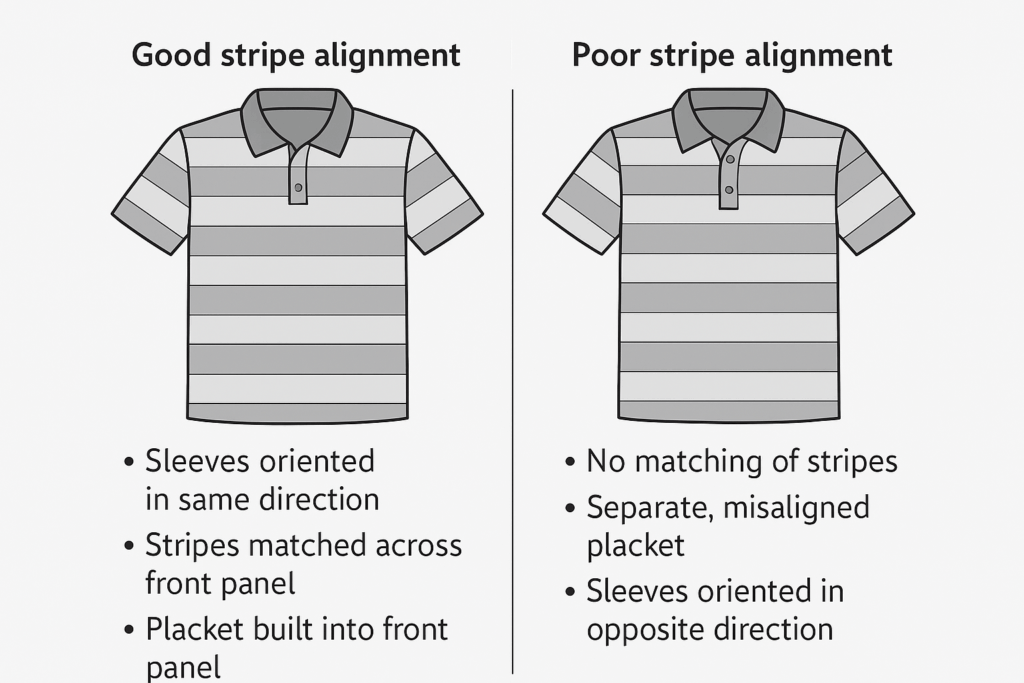

Professional tailoring instructions often factor in:

- Pattern directionality (e.g., pile, nap, prints)

- Fabric behavior (e.g., stretching, shrinkage, skew)

- Design intent (e.g., symmetry, seam alignment)

- Ease of assembly during sewing

Matching Fabric to Design

To create a high-quality garment, designers must balance:

- The intended silhouette

- The fabric’s drape and weight

- The fabric’s reaction to cutting and sewing

For example:

- A slim-fit thermal shirt needs a ribbed knit that won’t stretch out of shape.

- A structured suit needs a woven fabric with crisp body and no stretch.

- A loungewear set needs a soft, stretchy knit for comfort and ease.

Misalignment between fabric and design leads to issues like:

- Poor fit or drape

- Difficult sewing processes

- Increased returns due to quality complaints

Best Practices for Designers and Technicians

- 🔍 Test fabric behavior before bulk cutting.

- 📐 Use software (e.g., AccuMark) to plan efficient layout and markers.

- 📘 Document directionality, alignment points, and seam matching clearly.

- 🧵 Train factory teams to follow detailed cutting instructions.

- 🪡 Develop multiple prototypes when using complex or unfamiliar fabrics.

Conclusion

To deliver a functional, aesthetic, and high-quality garment, fabric selection and cutting technique must be synchronized. Garment professionals should understand how design intent, fabric characteristics, and technical layout influence cost, quality, and final product usability. The more detailed and thoughtful the planning, the more successful the outcome — both in production efficiency and customer satisfaction.